EFB Pellet Plant

This EFB pellet plant solution is an advanced, industrial-grade production line. It applies to biomass pellet production with a capacity of 0.6-40 T/H. Through multi-stage processing, it efficiently converts empty fruit bunches into high-quality fuel pellets. We also provide turnkey solutions and customized solution.

advanced efb Pellet plant solution

Our EFB pellet production solution features advanced equipment for producing pellets of various sizes. This solution produces EFB pellets with diameters ranging from 4 to 12 mm and lengths of up to 4–5 times the diameter. It fulfills your high-standard pellet specifications.

Additionally, it incorporates a robust raw material processing section. The processed empty fruit bunches meet optimal pelletization standards, delivering high formation rates while reducing costs and maximizing raw material utilization.

We also offer solutions with varying capacities and automation levels, which can be tailored to your diverse production requirements. The production capacity of these lines ranges from 0.6 to 40 T/H. Highly automated solutions meet the demand for high efficiency and low costs. Semi-automated lines save space and reduce investment costs. Whatever solution you choose, you can expect a rapid return on investment.

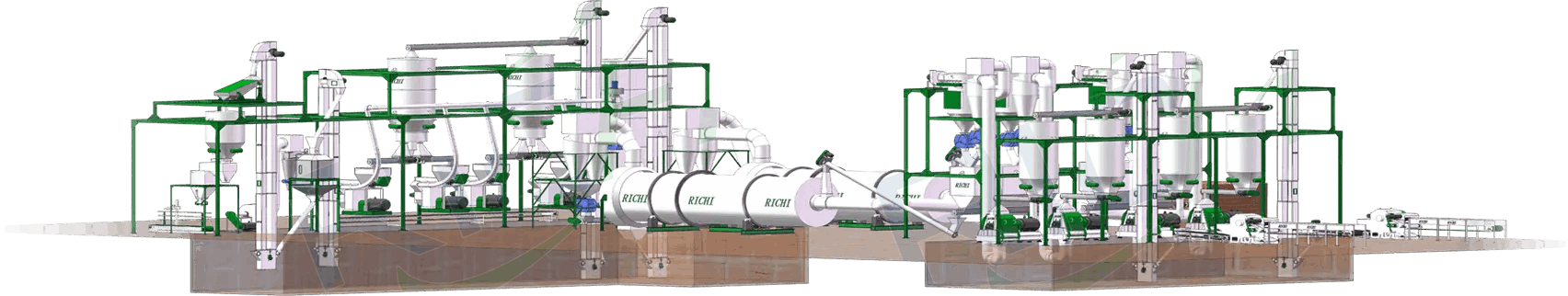

Complete process flow

The following is the standard production process.

Crushing

Drying

Pelletizing

Cooling

Screening

Packaging

application of EFB pellet plant solution

Besides the EFB pellet factory, our solutions has a wide range of applications. As well as producing premium biomass fuel, it can supply raw materials for organic fertilizer and biochar production, and enable the making of livestock bedding. Choose our EFB pellet making plant solution to take your EFB pellet processing to the next level.

Process Flow of EFB Pellet Plant

In order to enhance production efficiency, this EFB pellet manufacturing line has been divided into several sections. Each section is equipped with high-efficiency production machinery and control systems. We also offer customized production processes to help you achieve the ideal pellet results.

01

Slicer Stage

Empty fruit bunches have a large size and are rich in plant fiber. Therefore, they require crushing before granulation. This step involves cutting them into smaller pieces to make them easier to crush and turn into pellets.

02

drying Stage

Fresh empty fruit bunches have a moisture content of between 55% and 65%. However, the ideal moisture level for granulation is just 15%–18%. Therefore, we have designed a large-capacity drying drum for this process. It delivers rapid, uniform drying results.

03

pelletizing Stage

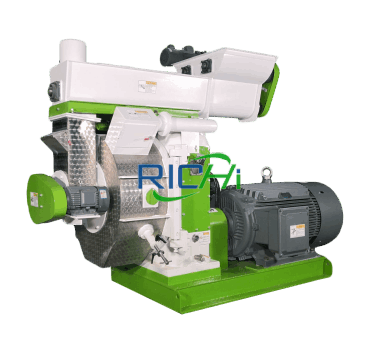

We have designed a specific husk pellet machine for processing EFB pellets. This machine offers multiple capacity models and can handle different raw material ratios. We can also provide customized pellet machines to meet your specific requirements.

04

cooling Stage

This section is equipped with rapid pellet cooling equipment. This enables the EFB pellets to harden quickly, achieving a stable structure. This not only facilitates subsequent packaging and transportation, but also extends the storage life of the pellets.

05

screening Stage

If you require uniform pellet size, this process stage can achieve that perfectly. We have designed multiple pellet screening devices. These devices can screen EFB pellets of various sizes, while also facilitating secondary granulation.

06

packing Stage

In this production section, we have designed packaging equipment with different automation levels. These machines ensure efficient packaging while reducing labor costs. We also offer various packaging methods, including heat sealing, wire sealing and hybrid sealing.

The above outlines the standard production process design for EFB pellet making plant. This system is designed based on actual production conditions, which is suitable for plant setup and related application fields. We also offer customized solutions to suit your raw materials and production needs. Contact us to obtain your tailored solution.

Raw Materials of EFB Pellet Production

This EFB pellet plant solution is specifically designed for processing husks. It not only produces EFB pellets, but also efficiently handles other husk pellets, such as crop husks and hard fruit shells. Whatever your raw material, it delivers perfect pellet production results.

Empty Fruit Bunches

palm shells

Walnut shell

Peanuts Shells

coffee husks

Almond Shells

Cotton seed hulls

rice husks

sunflower seed shells

Corn Cobs

In addition to these materials, this solution can also process mixed-ratio feedstock into pellets. For instance, adding some wood chips can improve pellet formation rates, as well as increasing the combustion heat output. If you require a customized pellet production solution, please feel free to contact us at any time.

Pellets from EFB Pellet production system

This industrial EFB pellet plant solution is also suitable for producing other husk pellets. These pellets feature a compact structure, hard texture and excellent combustion performance. If you’re looking for a production line solution for manufacturing high-quality pellets, you can rely on us.

EFB pellets

This production system is equipped with powerful crushing equipment. It can pulverize high-fiber empty fruit bunches into powder. Our EFB pellet mill features an innovative roller system and ring die. These factors combine to ensure perfect EFB fiber pellet production.

peanut husk pellets

This production line is also ideal for processing peanuts. The highly efficient drying system ensures the material has the optimal moisture level. Whether you are producing peanut shell fuel pellets or bedding material, this system will consistently deliver high-quality results.

Sunflower seed husk pellets

If you need high-quality sunflower seed husk pellets, this production line is ideal. We can also provide efficient raw material cleaning screens for this process. Furthermore, by adjusting the pelletizer parameters, it can produce pellets of various sizes.

coffee husk pellets

This production line can also produce coffee husk pellets for different applications. Such as animal bedding and fuel pellets. It features highly efficient cooling and packaging systems for the pellets. This ensures high quality while reducing material waste and labor costs.

Customization of EFB Pellet Plant Capacity

We provide customized capacity for all husk pellet production lines. Regarding EFB pellet production, we offer capacities solutions from 0.6 to 40 T/H, or even higher. Consequently, they are suitable for pellet production at various scales. If you would like further information, please feel free to contact us.

0.6-40 T/H

EFB Pellet plant

This pellet plant solution is designed to meet standard capacity requirements. We offer tailored equipment configurations and process segments. Therefore, it is ideal for palm EFB pellet making plant, oil mills, plantations and similar operations. If you require a quick start-up, we recommend our turnkey solution.

0.6-1 T/H

1-2 T/H

3-4 T/H

5-6 T/H

7-8 T/H

8-10 T/H

11-12 T/H

15-20 T/H

20-40 T/H

Configuration of EFB Pellet Plant

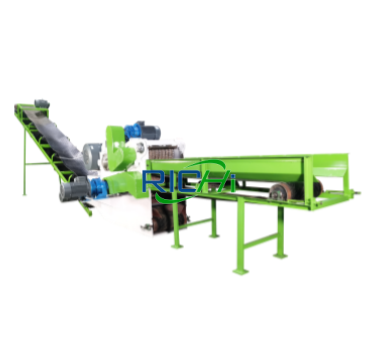

Raw Material Slicer

This is a high-capacity twin-shaft crusher. Its internal blades are made of 6GrW2Si, which offers excellent hardness and wear resistance. It efficiently crushes empty fruit bunches into fragments sized 20–40 mm.

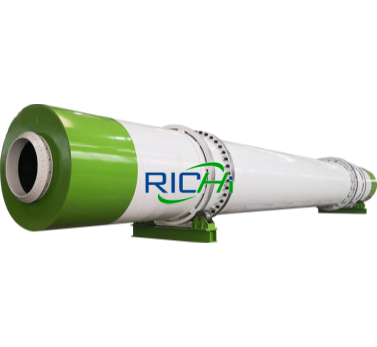

Drum Dryer

The drying drum has a dual-barrel design with inner and outer cylinders. The internal baffle plates mix materials thoroughly with hot air. It dries powder from empty fruit bunches to an ideal moisture level for granulation.

eFB Pellet Machine

This pelletizer comes in multiple models and delivers higher pellet formation rates. With a dual-roll system and an innovative ring die, it can handle complex feedstocks and achieve optimal compression ratios.

Counterflow Cooler

Its unique structural design allows cold air and pellets to flow in opposite directions. This allows pellets to cool gradually to room temperature. Its high level of automation and octagonal structure minimize material loss.

Rotary Classifier Screen

This device can separate pellets of three different sizes. It causes the pellets to move in a circular motion across a horizontal surface. Consequently, it achieves high screening accuracy with minimal vibration.

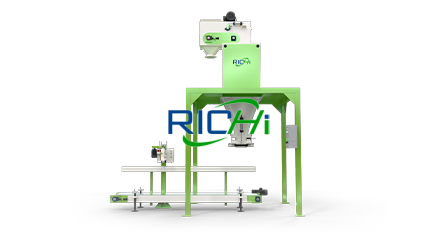

Automatic Bagging Scale

This packaging scale is highly automated. It allows for standardized weighing and packaging, thereby reducing waste and labor costs. There are also multiple models and feeding options to choose from.

The above outlines the primary equipment for the EFB pellet factory setup. In addition to these components, we also supply auxiliary devices, including screw conveyors, pneumatic conveying systems and storage bins. All equipment is customizable. We welcome your enquiries at any time.

GLOBAL CASES

Our EFB pellet production solutions have been validated by customers around the world. They boast advanced production capabilities and deliver high returns on investment. We provide the most comprehensive services, whether you require a small-scale production line or a turnkey solution.

CUSTOMER REVIEWS

Our EFB pellet production solutions have earned recognition from clients worldwide. We also provide attentive pre-sales and after-sales services. The following customer reviews provide further insight into our EFB pellet plant equipment and services.

Click to chat with us online

VIDEOs of EFB

PELLET plant production

Our pellet plant projects have provided convenience for numerous EFB pellet manufacturers. These pellet plant equipment can handle a wide range of complex tasks. The videos below showcase their smooth operation around the world.

EFB Crushing Section

EFB Pellet machine Tial Run

EFB Pellet Plant In Malaysia

Frequently Asked Questions

With years of industry expertise, we have built up extensive experience in project services. Therefore, we understand the concerns you may have when choosing an solution for your EFB pellet plant. Below are our answers to the most frequently asked questions. If you have any further questions, please feel free to contact us at any time.

What is the calorific value of the pellets produced by this EFB pellet processing solution?

+

Our palm biomass pellet line equipment boasts highly efficient pelletizing capabilities. The EFB pellets produced undergo high-intensity compression, achieving a calorific value of between 3,800 and 4,300 kcal/kg. This value may vary slightly depending on your specific raw materials.

While the calorific value of the pellets is slightly lower than that of wood pellets, the raw material costs are significantly lower. Unlike rice husk pellet production, this system can process a wide range of harder shell materials.

Therefore, it has broad applicability and can reduce investment costs. Producing EFB pellets offers excellent economic advantages.

Is there a difference in design between EFB pelletizer and wood pellet machine?

+

Absolutely. The EFB pelletizers we offer are specialized equipment for producing EFB pellets. They feature thickened molds and alloy materials, enabling them to handle high-fiber, shell-based raw materials. Their internal structure is significantly more wear-resistant than conventional wood pelletizers.

We also provide wear-resistant pelletizers with an extended service life. For example, wood chip pellet machine, rice husk pellet machine, sawdust pellet machine, peanut shell pellet machine, hay pellet machine and much more.

How should an EFB pellet plant supplier plan the budget?

+

The EFB pellet plant cost depends on the following factors:

Firstly, consider the raw material situation. If your raw material is fresh empty fruit bunches, you will require crushing and drying equipment.

Secondly, consider the level of automation required — we offer fully automated and semi-automated production line solutions. You can choose the option that best suits your needs.

Finally, select the capacity that best matches your production scale. Generally, small-scale lines require lower investment, while large, fully automated biomass pellet plants incur higher costs. Our palm biomass pellet line offers lower investment costs and faster payback periods, making it an ideal solution.

Does the EFB pellet plant require specialized operators?

+

Our production lines have a simple structural design and are user-friendly. The equipment comes with an operation and maintenance manual to facilitate future maintenance.

We also provide on-site installation and operational training services for EFB pellet manufacturers. This includes methods of operating, precautions and maintenance of the production line. Users without specialized production experience can quickly master the operation methods.

Does this production system generate high ash content during operation?

+

Our production line is eco-friendly and energy efficient. All of the equipment features innovative designs that comply with multiple international environmental standards. These designs significantly reduce ash content during production.

Additionally, proper processing of the raw materials further lowers ash levels. Our specialized crushing and drying systems effectively control dust generation.

Furthermore, we have installed pneumatic conveying systems and material filtration devices at critical stages in the production process. Together, these measures meet your low-ash requirements. (View YouTube)