Rice Husk pellet Machine

RICHI manufactures professional rice husk pellet machines. Our equipment features scientific design and undergoes rigorous testing. They meet high-quality standards and can accommodate rice husk pellet production across various capacities.

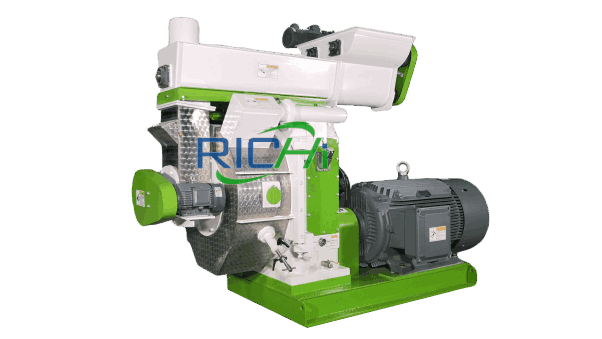

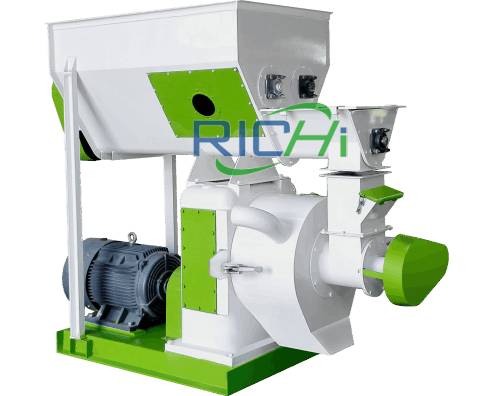

Efficient Rice Husk Pellet Machine

Our rice husk pellet making machine produces denser pellets. These pellets provide a clean energy alternative to coal and natural gas, delivering higher combustion heat with low emissions.

By processing rice husks through a pelletizer, you can produce supplementary feed suitable for ruminants that enhances digestion and nutrient absorption. These uniformly textured pellets also have excellent water absorption properties, making them ideal for use as bedding material for poultry and livestock.

Our equipment boasts an energy-efficient and eco-friendly design. Besides reducing dust emissions and saving on material costs, it lowers production energy consumption by 20%. It is the ideal solution for farms and biomass pellet plants looking to reduce energy consumption and achieve environmental goals.

How does a rice husk pellet machine work?

RICHI rice husk pellet mill operates at a high temperature of 80°C during the pelletizing process. This improves the binding properties of the raw material, resulting in high-quality pellets.

Thanks to professional structural design, it operates more efficiently.

First, you need to ensure that the raw materials are clean and in the form of a fine powder, with a particle size of 3–5 mm or finer. This enhances the efficiency of the pelletizing process. The materials then enter the anti-caking bin, which is equipped with two rollers to prevent agglomeration of the powder and ensure rapid delivery.

Then, material may accumulate at the feed inlet of the pelletizing chamber. A forced feeder is installed here to ensure fine powdered raw materials enter smoothly. These materials then enter the ring die under the squeezing force of the twin rollers. The sustained high pressure effectively compresses the material, which is then extruded through the die holes. This structural design produces denser pellets.

Passing through the ring die aperture, rice husk feedstock forms uniformly textured cylindrical pellets. Subsequently, these pellets are cut into standard lengths by blades mounted on the inner shell. The finished pellets then discharge through the outlet beneath the pelletising chamber.

The aperture of ring die can be customised from 4 to 12 mm, accommodating a wider range of pellet sizes. The ring die features a scientifically optimised design to achieve the ideal compression ratio. When combined with the powerful pressure exerted by the dual rollers, it produces longer rice husk pellets.

Scientific Design

As a leading manufacturer of advanced pelletising equipment, our rice husk pellet machine benefits from years of research and technological innovation, delivering high efficiency and energy savings. Its scientifically engineered design is unmatched by conventional pelletisers. It can process a wide range of raw materials to meet various pelletizing requirements.

In addition to outstanding pelletizing capabilities, our pellet mills are available in a range of production capacity models to meet all your output requirements. We can also design customized rice husk pellet maker based on varying production standards to fulfill your specific pellet needs.

01

Feed Inlet

It is equipped with an arch-breaking feeder featuring counter-rotating paddles to prevent material buildup and ensure smoother feeding.

02

Pelletizing chamber Inlet

This is equipped with a forced feeding device that pushes material accumulated at the inlet of the pelletising chamber into the bin.

03

Double-Roll System

Unlike the rollers in feed pellitizers, this system has a larger working area, making them more suitable for processing various lightweight materials.

04

Ring Die Mold

Due to an innovative design of the ring die and die holes, these moulds achieve optimal compression ratios and meet stricter pelletisation standards.

05

Power System

Each rice husk pellet machine is equipped with a robust, industrial-grade Siemens motor to ensure smooth operation throughout the process.

06

Ventilation Outlet

The design incorporates outlets and fans that extract high-temperature steam from the granulation chamber promptly, thereby safeguarding the production environment.

Parameters of Rice Husk Pellet Machine

| Model | MZLH320 | MZLH350 | MZLH420 | MZLH520 | MZLH678 | MZLH768 |

| Main Motor Power(kw) | 22 | 37 | 90 | 132 | 185 | 250 |

| Breaker Feeder Power(kw) | 2.2 | 2.2 | 3 | 3 | 3 | 4 |

| Forced Feeder Power(kw) | 0.75 | 0.75 | 1.5 | 1.5 | 1.5 | 1.5 |

| Ring Die Inner Diameter(mm) | 320 | 350 | 420 | 520 | 673 | 762 |

| Pellet Diameter(mm) | 4-12 | |||||

| Capacity(T/H) | 0.5-0.6 | 1.0-1.2 | 1.8-2.0 | 2.8-3.0 | 4-5 | 6-8 |

The above table details the power ratings and production capacities of rice husk pellet mills. You can choose the most suitable model based on your requirements, or consult us for tailored recommendations. If you require alternative production capacities or pellet sizes, we can provide bespoke design services.

Advantages of Rice Husk Pellet Machine

With over three decades of production expertise, we have extensive experience in manufacturing rice husk pellet making machine. Our products have been tested by customers worldwide and represent the latest advances in pellet production technology, delivering the results you want.

Applications of Rice Husk Pellet Machine

Our highly versatile pellet machines can be used to produce rice husk pellets from a wide range of raw materials. Regardless of the feedstock selected, our equipment consistently delivers optimal production results.

Processable Raw Materials

The raw material is usually rice husks. In addition to this, our rice husk pellet mill can efficiently pelletize other materials, such as peanut shells, cottonseed hulls, sunflower seed husks, and even harder materials. If you require processing for other specialized raw materials, we can provide tailored equipment solutions.

Rice Husk

Peanut Shell

Sunflower Seed Husk

Cotton Seed Husk

Walnut Shell

Coconut Husk

The Perfect Pellets

Our rice husk pellet machine deliver excellent pellets. These pellets produced by it have a compact structure and higher density, which significantly enhances their calorific value. Their stable structure also makes them easy to transport and store.

Even when processing hard-shelled raw materials, it consistently produces exceptional quality pellets. We also offer customised solutions to meet your specific pellet production needs.

Below are pellets produced from various raw materials using our equipment. By selecting our rice husk pellet mill, you can also manufacture flawless pellets.

Rice Husk Pellets

Peanut Shell Pellets

Sunflower Seed Husk Pellets

Walnut Shell Pellets

Cotton Seed Hull Pellets

Coconut Shell Pellets

Coffee Husk Pellets

Palm Kernel Pellets

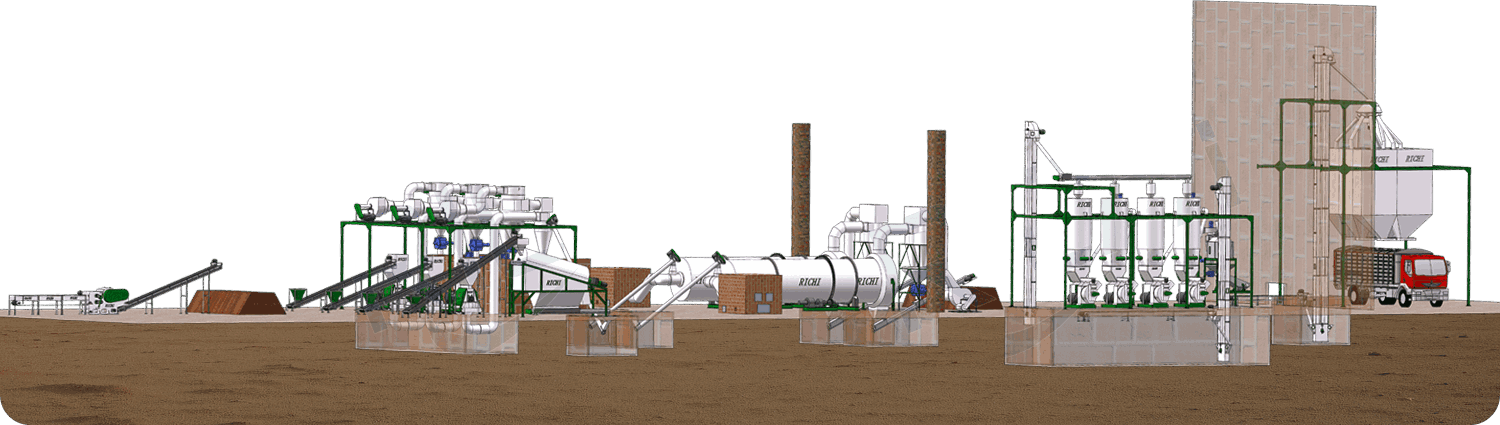

Rice Husk Pellet Production Line

We supply specialized rice husk pellet machines and complete rice husk pellet production lines with capacities ranging from 0.6 to 100 T/H. These lines feature scientifically rationalized configurations that incorporate high-efficiency equipment and flexible auxiliary units. Below is an overview of the standard rice husk pellet production process. Furthermore, we provide turnkey production solutions tailored to particular raw materials and operational requirements.

01

Cleaning

Rice husk materials usually contain impurities. We offer a variety of configurable devices for cleaning these materials according to specific needs. The cleaning process removes contaminants such as metal, plastic and dust.

02

Drying

The ideal moisture content for rice husk is 15–18%. Excessively high or low moisture levels can have an adverse effect on rate of pellet formation. This stage uses a large-capacity dry drum to enable rapid and uniform drying.

03

Pelletizing

The rice husk pellet mill is a key equipment in the production line. Our pellet mills can handle standard rice husk pellet production and more demanding tasks. They offer various production capacities and tailored equipment solutions.

04

Cooling

Due to the high-temperature steam conditions, the resulting pellets are damp and pliable, making them unsuitable for transportation and storage. Consequently, an efficient cooling device is essential to rapidly reduce the temperature.

05

Screening

To ensure uniform pellet sizes in the finished product, we have designed grading screens, which are available in multiple formats. This stage also separates smaller particles for re-pelletisation, thereby helping to minimise material wastage.

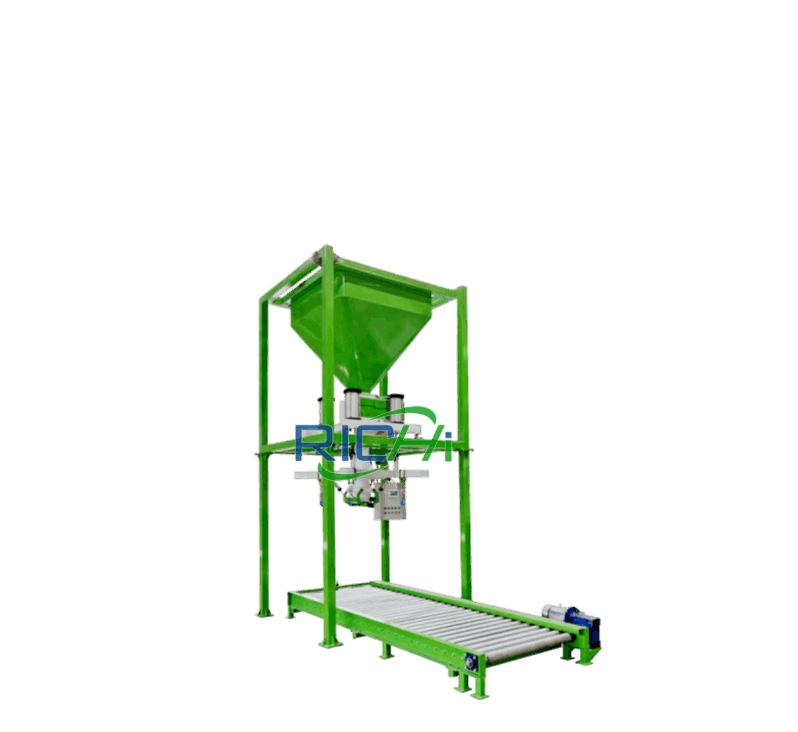

06

Packaging

Our packaging machines include tonne-bag scales and fully automatic scales, with options to suit your requirements. They enable fully automated weighing and packaging, ensuring uniform specifications and reducing labour costs.

Application Scenarios

Our rice husk pellet machines have successfully enabled clients worldwide to produce perfect pellets. The majority of our customers use the devices to process pellet fuel, animal roughage and organic fertiliser fermentation materials. With a range of robust, stable machine models, our solutions cater to biomass pellet plants and livestock farms of all sizes.

We offer free consultations on production solutions and equipment around the clock.

We also provide husk pellet project planning and production line turnkey solutions.

Biomass husk Pellet making Plant

Livestock Farms

Rapid Customisation Services

High Return on Investment

Global Projects

Drawing on three decades of industry expertise, we have successfully delivered high-quality rice husk pellet mills to over 150 countries and regions worldwide. We offer a range of collaborative projects, including the sale of individual rice husk pellet maker, production line solutions and turnkey services.

Rice Husk Pellet mill for Sale Kazakhstan

The raw materials for this project are rice husks and sunflower seed hulls, with a target pellet diameter of 6-8 mm. The client selected our pellet machine to produce rice husk feed pellets.

Thailand Rice Husk Pellet Production Project

The client bought our pellet machine to produce cat litter. The raw materials used are locally sourced rice husks and cassava. Our machine produces pellets measuring 4–6 mm in diameter.

Rice Husk Pellet Machine for Sale Vietnam

The client’s raw material for this project is rice husks, and the aim is to produce rice husk pellets for sale. We supplied a high-efficiency pellet machine with a capacity of 2 T/H.

USA Rice Husk Feed Pellet Project

This client runs a large livestock farm and needs to process a lot of rice husks and peanut shells into animal feed. Our pellet machine has enabled them to produce perfect results.

Rice Husk Pellet plant in Indonesia

This project uses rice husks and wood chips. The client owns a rice husk pellet plant and requires high-quality rice husk fuel for sale. The equipment effectively meets the mixed peletization.

Rice Husk Pellet Machine for Sale Dutch

The client has a lot of rice husks on their own farm and needs to produce biomass husk pellets for combustion. We provided equipment that combines high output with superior quality.

Indian Rice Husk Pellet Production Plant

In this case, the material was hard coconut shells, and target pellets were 5–6 mm cat litter. We therefore supplied a high-efficiency, precision pelletizer that perfectly met the client’s needs.

Bangladesh Rice Husk Pellet Processing Plant

The client required high-capacity pelletisers and efficient raw material handling systems. We supplied an energy-efficient production line that achieved the desired outcome.

Why Choose RICHI?

We are a leading brand in the manufacturing industry for pellet equipment.

RICHI Machinery was established in 1995, and we have remained dedicated to providing customers with the best pellet solutions. We are driven by customer satisfaction and are engaged in the research of pellet machinery. To date, we have successfully supplied high-quality rice husk pellet machine to clients worldwide.

Drawing upon extensive customer service experience, we have a thorough understanding of your production needs and the challenges at every manufacturing stage. Consequently, we offer an integrated solution combining pre-sales and after-sales support to protect your rice husk pellet production operations.

Our after-sales service includes a one-year warranty and a prompt response to any quality issues. To ensure rapid dispatch of components, we also maintain a global network of spare parts. If you encounter any production challenges, we will provide solutions to help you resume operations swiftly. We also offer the following services:

Free consultation Service

At RICHI, our experienced engineers and sales team are ready to provide free consultations for rice husk pellet making machines. We understand our clients’ production requirements and queries, so feel free to ask us any questions you have about the production solutions.

Customised Equipment Service

Should you have specific requirement for output and standard for pellets, we can provide tailored solutions to meet your needs. Our specialist technical team and large-scale manufacturing facilities can accommodate all your equipment needs.

Turnkey Production Solutions

Besides exceptional rice husk pellet maker, our production line solutions have earned the trust and support of clients. Our turnkey solutions, in particular, offer complete service including project planning, construction, equipment installation and operator training.

Other Related Production Equipment

RICHI operates large-scale manufacturing facilities for equipment. As well as advanced rice husk pellet machine, we design and manufacture other high-efficiency production machinery. This includes cleaning screens, drum dryers, coolers and automatic packaging scales. They also play vital roles within rice husk pellet production lines.

Cleaning Screen

It rapidly separates impurities from powdered materials through high-frequency vibration.

Drum Dryer

It features a large capacity and a dual-barrel design for efficient, uniform drying of materials.

Cooling Machine

This machine rapidly cools pellets to maintain optimal structure.

Packaging Scale

It provides fully automated weighing and uniform packaging. Packaging options include heat-sealed bags and conventional sacks.

Frequently Asked Questions

Thanks to our global customer service, we are familiar with the various issues that you may face during the rice husk pellet production process. These include rice husk pellet machine price, models, equipment maintenance, raw material selection and after-sales support, among others. Our compiled responses are provided below for your reference.

–

Is it necessary to use a binder when operating a rice husk pellet making machine?

Typically, it is not necessary. Although rice husks contain lower levels of lignin than wood materials, this has minimal impact on the process of making pellets. Our rice husk pellet maker operates at a temperature of 80°C. When combined with the high-intensity compression from the roller system and die, this softens and plasticises the lignin. Consequently, the rice husk material binds together tightly.

Only when the raw material is particularly dry or has a complex composition, is it necessary to improve the forming effect by adding a small amount of moisture or a natural binder.

–

How to maintain and service a rice husk pellet mill?

A comprehensive user manual is provided upon delivery of the rice husk pellet machine. This document details the operational procedures and key points for routine maintenance. We advise you to adhere strictly to these instructions when servicing the equipment.

Our machinery uses robust stainless steel and alloy materials to enhance wear resistance. Regular inspection of wear components, including press rollers and moulds, is essential. If mould wear reaches the warning line, replace the ring die promptly to prevent compromised pelletisation quality and output.

It is important to maintain thorough cleanliness to prevent corrosion caused by material residue. After shutdown, clear all residual material promptly to ensure the unit remains dry and clean, thereby safeguarding subsequent pellet production.

–

What other materials can the rice husk pellet machine process besides rice husks?

Our versatile and adaptable equipment can handle most types of biomass material. Beyond rice husks, it can process various shell materials and other agricultural and forestry residues. These include sunflower seed shells, cotton seed hulls, peanut shells, walnut shells, wood shavings, sawdust and various types of crop straw. If you have any questions, please do not hesitate to contact us.

We also offer bespoke customisation for specialised raw materials and production capacity requirements. We will adjust the structure of the rice husk pellet machine based on the characteristics of different materials, their compaction difficulty, and actual operational needs to ensure optimal production outcomes.

–

How to select the appropriate rice husk pellet making machine?

Selecting the right model is crucial for effective pellet production. The following factors should be considered:

Firstly, determine your required output. You should also consider whether the produced rice husk pellets will be sold commercially. Select a rice husk pellet machine based on output volume and intended use.

Secondly, you must assess the characteristics of your raw materials. For example, evaluate the moisture content of your feedstock to determine whether auxiliary drying equipment is required. If the rice husk material contains impurities, it is advisable to incorporate a raw material cleaning unit.

Finally, select a reputable equipment supplier. Comprehensive pre-sales and after-sales support can help resolve issues that may arise during production. Key considerations include long-term warranties, the speed of spare parts delivery and ongoing technical support. We offer thorough pre-sales and after-sales support to facilitate your long-term, stable pellet production. And don’t worry about this rice husk pellet machine price, we can offer a discount!

–

Does the rice husk pellet machine require specialized operators?

Not at all. We have a strong grasp of our customers’ production needs and are dedicated to producing user-friendly equipment. Upon delivery, we provide comprehensive operating manuals and video tutorials. Even if your staff lack prior pellet production experience, the operation is straightforward enough for them to master quickly.

Furthermore, for production line solutions, we offer on-site installation services. The engineers will assist with equipment wiring connections and parameter adjustments, as well as providing operator training. Following this training, your ordinary workers will be ready to take up their duties.