EFB Pellet Plant

in Malaysia

Pellet Diameter:

8mm

Raw Material:

Empty fruit bunches, wood chips

Application:

Carbonizing EFB pellet production

Project Name:

Automated EFB Pellet plant in malaysia (Turnkey Project)

capacity:

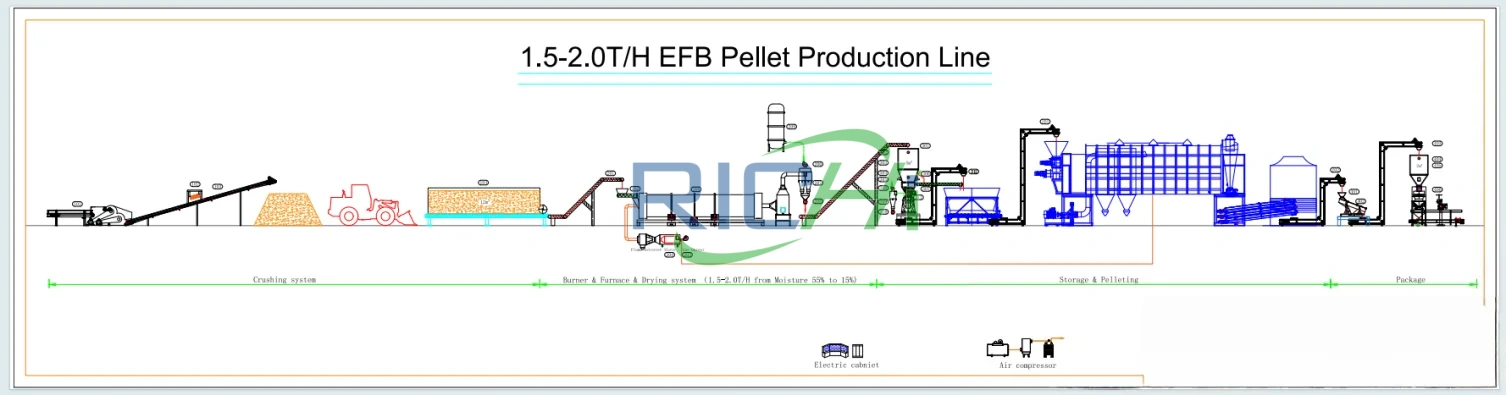

1.5-2 T/H

Malaysian eFB Pellet Market

Malaysia boasts not only large-scale palm cultivation, but also a well-developed palm oil industry. Consequently, it produces vast quantities of empty fruit bunches each year. The local government prioritizes the recycling of this waste material, and considers it a key part of green economic development. Overall, the EFB pellet plant Malaysia holds promising prospects for growth.

Although the EFB pellet factory Malaysia is gradually emerging, the quality of products on the market is inconsistent. Many EFB pellet plants struggle to achieve the ideal pellet formation rate, which often results in loose structures and low calorific values. While EFB pellet production offers the advantages of low cost and high returns, optimizing production technology is equally crucial.

Subsequently, several manufacturers decided to undertook optimization and upgrades. This EFB pellet plant in Malaysia is a case in point. Using the production line solution we provided, this manufacturer has successfully produced higher-quality fuel products. These pellets meet the highest market standards and deliver significant economic benefits to this EFB pellet manufacturing plant Malaysia.

CLIENT PROJECT DETAILS

Our client is a small EFB pellet plant in Malaysia. This project uses empty fruit bunches as raw material, sourced from surrounding oil mills, which have a relatively high moisture content. Their previous production line was simple, making it difficult to ensure consistent output and quality. Consequently, upgrading and optimizing the production line equipment is necessary.

As the client needed to ramp up production quickly, they selected our turnkey solution. Subsequently, after analyzing their production challenges, we provided a highly efficient production line. This line features a powerful drying system, which is ideal for processing their high-moisture empty fruit clusters. The quality of the resulting pellets has also been significantly improved.

The moisture content of the empty fruit clusters is 55%. However, by utilizing our drying equipment, this level can be reduced to the ideal pelleting level of 15%.

The project of empty fruit bunch pellet plant Malaysia is energy-efficient and environmentally friendly. The equipment we provide meets these needs fully, achieving a 20% reduction in energy consumption.

Solutions to Production Issues

The project of EFB pellet plant in Malaysia encountered several challenges during its implementation. These included site height restrictions, the heat source for the drying drum and the storage of pellets to prevent moisture. Ultimately, with the help of our professional engineering team, these issues were resolved.

The following are also common issues encountered in production of most EFB pellet production.

This project requires large-scale units for processing raw materials and conveying equipment. Consequently, the production line requires a lot of space. Our engineers have extensive project experience and have achieved an optimal layout for each process section.

The selection of heat sources for the drying unit has a direct impact on production costs. This EFB pellet plant Malaysia uses production waste as the heat source for drying. This is the most economical and eco-friendly heating method, enabling the maximum utilization of raw materials.

According to the customer, previous EFB pellets were prone to moisture absorption, which affected sales. Therefore, we installed storage bins at critical points. When combined with specialized moisture-proof packaging bags, this provides full protection against moisture.

The client requires EFB pellets with specific mixing ratios. Therefore, we have optimized the pelletizer parameters to achieve the optimal compression ratio. Together with a carbonization treatment unit, this improves the combustion performance of the pellets.

Process Design for the EFB pellet plant in Malaysia:

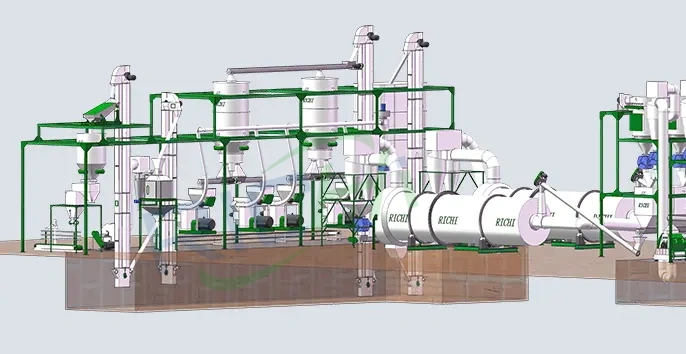

In order to meet higher standards of pellet quality, we have developed a highly automated EFB pellet production line. This line features robust main equipment, efficient auxiliary devices and control systems. Accordingly, it facilitates highly efficient operation at every stage. It is now the backbone of this EFB pellet plant Malaysia.

01

Crushing

EFB has a high fiber content, which means that direct pelleting would compromise the forming results. Therefore, this section has a powerful crushing unit to convert the material into a powder for easier pelletization.

02

Drying

The customer’s EFB has a relatively high moisture content, so we designed this drying section. By using a drying drum with a hot air furnace as the heat source, they can reduce the moisture content of the raw materials.

03

Pelletizing

We offer high-efficiency EFB pellet machine, which has a production capacity of 1.8–2.0 T/H. It produces EFB pellet with a perfect structure. When paired with a 4 m³ storage bin, this ensures a smoother integration process.

04

carbonizing

To meet customers’ higher standards for pellet quality, a specialized carbonization process is employed in this stage. This results in upgraded EFB pellets that deliver superior combustion performance.

05

screening

To ensure optimal pellet specifications, we have installed a high-frequency vibrating screen for our customers. This unit connects to the prior and subsequent processing stages via a Z-type bucket elevator.

06

Packaging

We provide our customers with a fully automatic packaging scale. This equipment helps to reduce labor costs. It features a front-mounted storage bin with a capacity of 2m³ for finished pellets.

Configuration for this project

For this project of EFB pellet plant Malaysia, the client required high energy efficiency and a high level of automation in the configuration. Consequently, we provided robust raw material handling equipment, high-efficiency pellitizer and automated packaging machinery. These solutions, combined with auxiliary systems, enabled the biomass pellet plant to achieve their production goals.

01

Crushing System

Our dual-shaft crusher boasts high capacity and robust performance. We use specialized dynamic balancing equipment to rigorously control rotor precision, which enables the effortless processing of materials of all difficulty levels.

02

Storage Bin

To ensure a smoother integration of the crushing and drying processes, and to minimize unnecessary downtime, we have provided our clients with a 12 m³ storage bin. It can temporarily hold crushed material awaiting drying.

03

Drying System

This drying drum has a dual-cylinder design with an inner and outer barrel. Additionally, a spiral agitator plate ensures rapid and uniform drying results. We have also incorporated a thermometer and control system for easy adjustment of the drying duration.

04

pelletizing System

This husk pellet machine is specifically designed for the production of EFB pellets. It incorporates a dual-roll system, an innovative ring die and a bridge-breaking feeder. These structural designs enable the machine to effortlessly pelletize raw materials of varying difficulty levels.

05

Screening System

For the screening stage, we offer a high-frequency vibrating screen. This machine uses a self-balancing vibration mechanism to deliver excellent screening performance. Its screen clamping mechanism enables quick and easy screen replacement.

06

Packaging System

To help our customer achieve high-quality product packaging, we offer fully automatic packaging scale. This device weighs and packages products automatically, reducing labor costs. When used with moisture-proof packaging bags, it also extends the storage life of pellet products.

The EFB pellet production line project began in 2025. Since then, the EFB pellet plant in Malaysia has consistently produced exceptional quality pellets. We have maintained a strong cooperative relationship with our client.

For this project of EFB pellet factory Malaysia, we provided comprehensive services, including pre-sales consultation, exclusive customization, post-sales follow-up and ongoing support. As an equipment manufacturer with over three decades of industry experience, we operate large-scale manufacturing facilities capable of delivering solutions tailored to all your EFB pellet production needs.

RICHI Services

Through years of customer service, RICHI Machinery has developed a comprehensive service system. This includes end-to-end solutions from equipment consultation and project planning to construction, worker training and so on. Just as we do for this EFB pellet plant in Malaysia, we provide optimal support for every pellet manufacturer.

Customized Solutions

RICHI has extensive experience in customer service. We can provide customized design solutions for EFB pellet production. Whether you require customization of a single machine or of an entire production line, we will ensure that your actual production needs are met.

Production Line Solution

We provide professional EFB pelletizers and production line solutions. They feature energy-efficient designs which achieve high forming rates and meet high quality pellet needs. By choosing our turnkey solutions, you can maximize your return on investment in the shortest possible time. (View YouTube)

One-Stop Service

All of our production equipment comes with a one-year warranty. We also have a global spare parts network, ensuring the rapid delivery of components such as ring dies and press rolls, which are prone to wear and tear. We also offer long-term technical guidance. You can contact us at any time.

Professional Manufacturer

RICHI operates large-scale, professional manufacturing plants. Each equipment that we deliver is meticulously designed and rigorously tested. To date, we have successfully completed over 2,000 outstanding pellet production projects worldwide. Partner with us to propel the growth of your EFB pellet plant.

Other Husk Pellet Production Line Solutions

Our husk pellet production line has a wide range of applications. In addition to the EFB pellet plant in Malaysia, it has gained the support and trust of other pellet manufacturers. Even hard fruit shells can be transformed into excellent pellets.

EFB Pellet Plant solution

The production line is suitable for manufacturing various oil palm processing residues. Such as, EFB, PKS, coconut shells, walnut shells, peanut shells, etc.

Sunflower Seed husk Pellet Production Line

It can efficiently process sunflower seed shells and produce pellets of various diameters and lengths.

Coconut Shell Pellet Production Line

It can crush hard coconut shells into a fine powder and process them into compact, plump pellets.

rice husk Pellet Plant solution

It boasts an efficient pelleting system that can produce high-quality fuel, animal feed, and bedding.

peanut shell Pellet Production Line

It can turn fluffy peanut shells into high-density pellets that can serve as fuel or agricultural substrates.