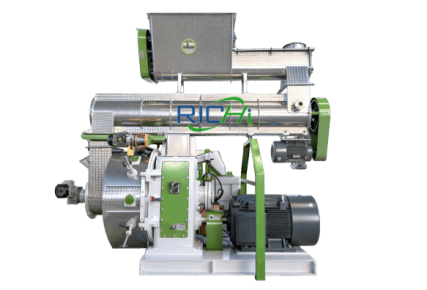

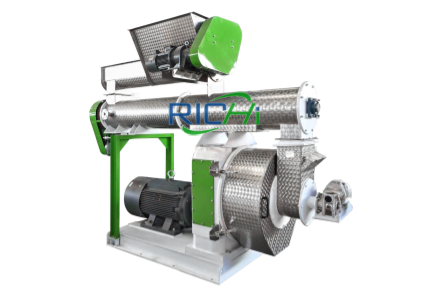

Wood Chip Pellet Machine

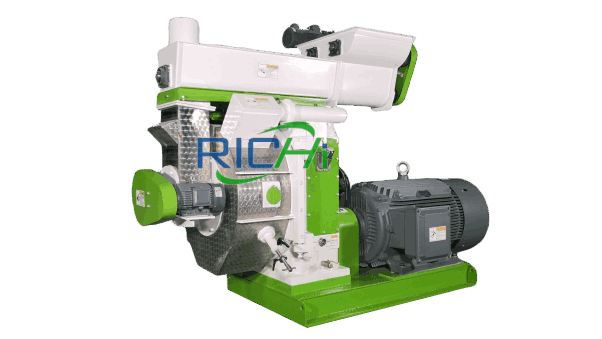

This wood chip pellet machine is an advanced, industrial-grade device. It features an excellent pelletizing system that can compress loose wood chips into compact wood pellets. We offer a range of production capacity options and customized equipment solutions.

industrial wood chip Pellet machine For Sale

We have many years of experience in manufacturing equipment. This industrial-grade production solution can meet all your production needs. With a robust structure and convenient installation, it is easy to operate.

This wood chip pelletizer machine can produce pellets in various sizes. The optimized die design can produce pellets with diameters ranging from 6 to 12 mm, with lengths up to five times the diameter. Even smaller pellets deliver high combustion heat.

It produces wood pellets with a stable structure. This makes them easy to transport and store, while also extending burn duration. As well as being energy-efficient and environmentally friendly, it enhances the rate of pellet formation. Overall, utilizing this equipment significantly reduces costs.

Parameters of Wood Chip Pellet machine

| Model | MZLH320 | MZLH350 | MZLH420 | MZLH520 | MZLH678 | MZLH768 |

| Main Motor Power(kw) | 22 | 37 | 90 | 132 | 185 | 250 |

| Breaker Feeder Power(kw) | 2.2 | 2.2 | 3 | 3 | 3 | 4 |

| Forced Feeder Power(kw) | 0.75 | 0.75 | 1.5 | 1.5 | 1.5 | 1.5 |

| Ring Die Inner Diameter(mm) | 320 | 350 | 420 | 520 | 673 | 762 |

| Pellet Diameter(mm) | 4-12 | |||||

| Capacity(T/H) | 0.5-0.6 | 1.0-1.2 | 1.8-2.0 | 2.8-3.0 | 4-5 | 6-8 |

The above outlines the primary specifications and production capacity of this wood chip pelletizer machine. Each model offers exceptional performance and energy-saving advantages. If you require additional specifications, we can provide bespoke solutions.

Advantages of wood chip Pellet machine

As professional wood chip pellet machine supplier, we are committed to technological innovation. Consequently, our equipment boasts a range of technical advantages. It delivers high-efficiency production and has a robust, durable design. We can provide you with the ideal wood pelletizer.

Production Process of wood chip Pellet machine

This pellet press machine has a unique structural design that enables highly efficient pelletizing processes. It can operate at higher temperatures, making it better suited to processing wood raw materials.

We provide highly efficient biomass fuel production equipment for sale.

The loose wood chips are first fed through a break-arch feeder. After processing by this device, the material enters the pelletizer smoothly. This high-temperature steam environment activates the lignin in raw material, enhancing its binding properties.

The material then undergoes intense compression by dual rollers and is extruded through the ring die apertures. At this stage, blades on the inner wall of the shell cut them into uniformly sized pellets. The finished pellets are then discharged from the bottom of the pelletizing chamber.

Following this process, the wood chip pellets achieve a higher quality standard. Once cooled to room temperature and fully set, they are ready for packaging and transportation. We also provide pellet production equipment for other process stages. Please contact us at any time to discuss your requirements.

Innovative Design

RICHI has a team of experienced designers that can customize production equipment to meet client needs. Our industrial-grade wood chip pellet machine incorporate a variety of innovative technologies, making them suitable for biomass pellet plants of all sizes.

Every wood pellet-making machine undergoes a rigorous testing process. We use professional dynamic balancing testers to carry out precise rotor inspections, which eliminates any imbalance during operation. This ensures our equipment meets safety standards and safeguards your production.

Additionally, to ensure production safety, each pelletizer is equipped with a robust electronic control system. This system promptly detects operational irregularities. The safety shutdown function reduces potential losses and enables issues to be identified and addressed promptly.

01

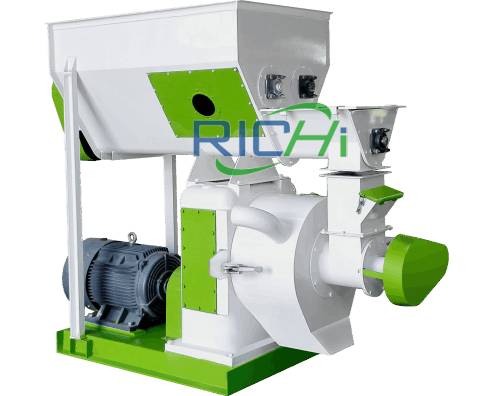

Arch-Breaking Feeder

This design features an enlarged, widened structure. Its internal mechanism comprises counter-rotating feed plates that effectively prevent material arching.

02

Forced Feeder

The device forces accumulated wood chips into the pelletizing chamber. This accelerates the production process and enhances capacity.

03

Double-Roll System

This dual-pressure roller system has been specifically engineered for biomass material. This design effectively aids the shaping of wood chips.

04

Ring Die Mold

It is made of 42 CrMo alloy steel, offering exceptional hardness and corrosion resistance. Its optimally arranged apertures increase output efficiency.

05

Exhaust Vent

This outlet allows water vapor within the granulation chamber to be vented. It protects the production environment and prevents pellets escaping.

06

Power System

Each pelletizer is equipped with an industrial-grade drive motor from Siemens. This enhances production efficiency while reducing maintenance costs.

Applications of wood chip Pellet machine

RICHI wood chip pellet making machine can efficiently produce pellets from various types of wood. It is ideal for capacities of over 300 kg/h. Examples include biomass pellet plants, heating systems and energy companies.

Processable wood Materials

Our equipment offers excellent compatibility. As well as wood chips, you can use other wood materials for production. If you’re looking for a versatile wood chip pelletizer machine, this is the ideal choice.

Wood Chips

Sawdust

Wood Shavings

Wood Blocks

Branches

Bark

Available Wood Pellets

In addition to wood chip pellets, this equipment can be used to produce other types of wood pellet. Unlike conventional wood pellet machines, it can handle more complex ratios of raw materials. Therefore, it can meet diverse pellet production needs.

We will provide the appropriate pelletizer based on your requirements and the conditions of raw materials. This includes various ring die hole sizes, production capacity models and parameters. If you require customization, our engineers will deliver a bespoke design.

The wood pellets below are produced using our wood chip pellet machine. If you need efficient equipment for making these pellets, please feel free to contact us at any time.

Wood Chip Pellets

Sawdust Pellets

Wood Shavings Pellets

Branch Pellets

wood Board Pellets

Log Pellets

Wood Bark Pellets

Wood powder Pellets

Global Projects

RICHI has extensive experience in manufacturing wood pellet equipment. We have provided superior project services to over 150 countries and regions worldwide. Whether a single wood chip pellet machine or complete production line solutions, they consistently deliver excellent performance.

Wood chip Pelletizer in Singapore

The raw materials for this project are wood chips and shavings. We have supplied a 2 T/H wood pelletizer, meeting the needs.

Wood chip Pellet mill for sale in Canada

This project involves turning waste boards and wood chips into 6 mm pellets. We provided all the production line equipment.

Wood chip Pellet project in Australia

This project is a customized solution. It includes a wood pelletizer with capacity of 2–2.5 T/H, as well as other production machinery.

Wood Chip Pellet plant in South Africa

The raw material is waste furniture wood, including wood blocks and chips. We provide a 2 T/H wood pelletizer.

biomass Wood Chip Pellet making plant in USA

This turnkey solution features a capacity of 10 T/H. We provide a production line incorporating customized pellet mill.

Wood Chip Pellet project in Bangladesh

This turnkey project has a production capacity of 20 T/H. We supplied the automated production line and large-scale wood chip pelletizer.

wood chip Pellet mill for Sale in Indonesia

The project uses sawdust and wood shavings as raw materials. We have supplied a 1.8–2.0 T/H pelletizer to produce 6 mm pellets.

wood chip Pellet production in Romania

The customer selected our 2–2.5 T/H wood chip pellet making machine to produce wood pellets measuring 8 mm in diameter.

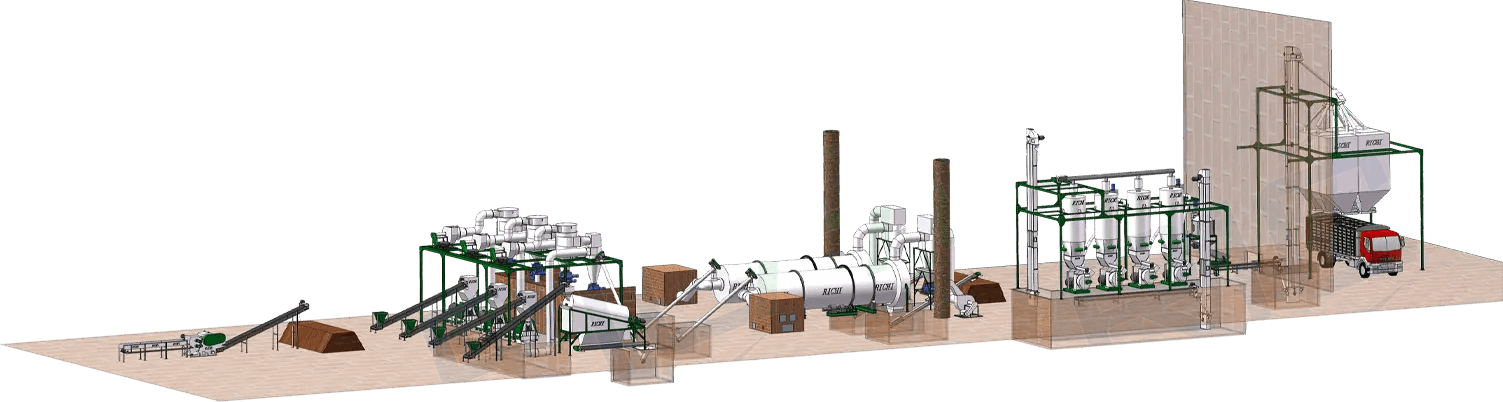

wood chip Pellet Production Line

We offer advanced wood chip pellet machine for sale and provide complete production line solutions. This production system features customizable capacities ranging from 0.6 to 40 T/H. Through segmented processing, it can significantly boost your production efficiency. Each wood pellet production line features energy efficiency and high performance. We can also deliver turnkey solutions to meet your more project requirements.

01

Crushing

Wood chip pellets can be produced from various types of wood. If your raw material exceeds 5 mm in size, this process is ideal for you. Our range of shredding equipment can crush the wood into uniform particles measuring 3–5 mm.

02

Drying

The ideal moisture content for producing wood chip pellets is 15–18%. If your wood has a higher moisture content, this section offers drying capabilities. We have designed an efficient drum dryer. It delivers rapid and uniform drying results to facilitate pelletization.

03

Pelletizing

Powdered wood shavings are prone to clumping, which can reduce output. Our wood pelletizer features multiple anti-clumping designs and an excellent ring die compression ratio. These factors allow it to consistently produce high-quality wood pellets.

04

Cooling

This stage rapidly cools the pellets in order to achieve a stable structure. This stage is essential if you require quick packaging and transportation. It not only facilitates subsequent packing, but also extends the storage life of the pellets.

05

Screening

If you require uniform biomass pellet specifications, we can offer efficient screeners. This process can separate pellets into different sizes to meet higher biomass pellet sales standards. Other materials that are screened out can undergo secondary pelleting.

06

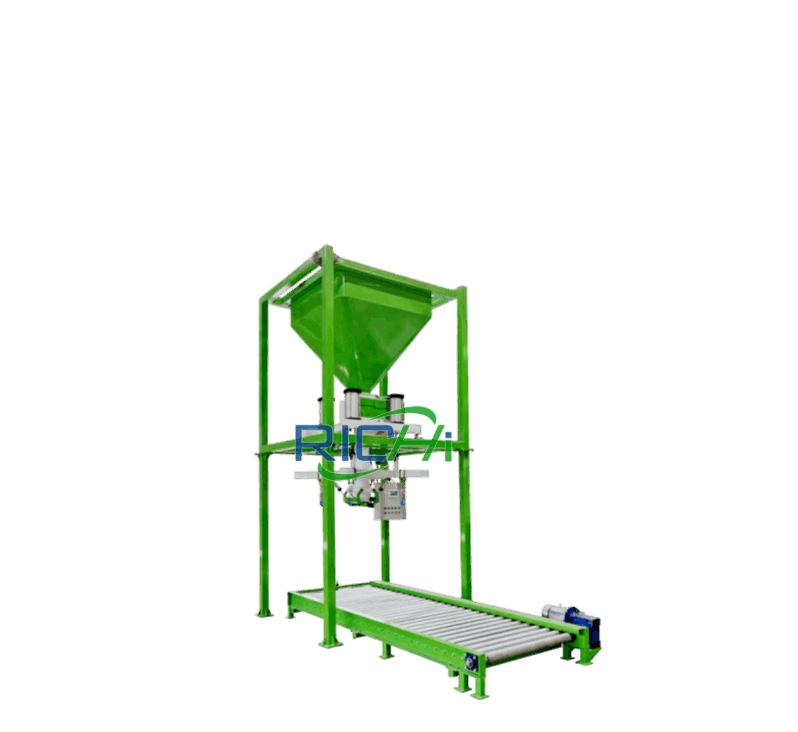

Packaging

We offer fully automated packaging units to help your efficient wood pellet production. You can choose different levels of automation and packaging methods based on your needs. This stage ensures high-quality packaging and reduces labor costs and pellet loss.

Application Scenarios

We provide advanced biomass fuel production equipment. Its rapid pelletizing capability meets the demands of high-efficiency production. It ensures premium pellet quality even with complex raw material ratios. Thus, it is suitable for various biomass pellet manufacturers, wood processing plants and heating applications.

This wood chip pellet production line features scientifically divided process stages. It also offers different automation levels. If you require an industrial-grade production solution, please feel free to contact us at any time to arrange a consultation.

We offer free consultations on production solutions and equipment around the clock.

We provide a one-stop service for wood chip pellet production projects.

Biomass wood Pellet Plant

Wood Processing Plant

Rapid Customization Services

High Return on Investment

Why Choose RICHI?

We offer industrial wood chip pellet machine for sale, along with the most comprehensive service.

RICHI Machinery was established in 1995, and we have remained dedicated to providing customers with the best wood chip pellet solutions. We are driven by customer satisfaction and are engaged in the research of pellet machinery. To date, we have successfully supplied high-quality wood pellet machines to clients worldwide.

Drawing upon extensive customer service experience, we have a thorough understanding of your needs and the challenges at every production stage. Consequently, we offer an integrated solution combining pre-sales and after-sales support to protect your wood pellet production operations.

Our after-sales service includes a one-year warranty and a prompt response to any quality issues. To ensure rapid dispatch of components, we also maintain a global network of spare parts. If you encounter any production challenges, we will provide solutions to help you resume operations swiftly. We also offer the following services:

Free consultation Service

At RICHI, our experienced engineers and sales team offer free consultations on the wood chip pellet making machine. We understand our clients’ production requirements and queries, so feel free to ask us any questions you have about the production solutions.

Customized Equipment Service

Should you have specific requirement for output and standard for pellets, we can provide tailored solutions to meet your needs. Our specialist technical team and large-scale manufacturing facilities can accommodate all your equipment needs.

Turnkey Production Solutions

Besides exceptional wood pelletizer, our production line solutions have earned the trust and support of clients. The turnkey solutions, in particular, offer complete service including project planning, construction, equipment installation and operator training.

Other Related Production Equipment

In addition to the wood chip pellet machine, we also supply equipment for other production stages. Below are some of the main units that are commonly used. RICHI boasts an experienced manufacturing team and large-scale equipment production facilities. Therefore, we can provide the ideal solution for your wood chip pellet production.

wood chipper

It can crush wood into particles of 0.5 mm-30 mm. Its screen mesh size can be customized.

Drum Dryer

It features a large capacity and a dual-barrel design for efficient, uniform drying of materials.

Cooling Machine

It rapidly cools high-temperature wood pellets to room temperature through counter-current cooling.

Packaging Scale

It provides fully automated weighing and uniform packaging. Packaging options include heat-sealed bags and conventional sacks.

Other pellet machines

We have also designed other innovative pellet machines. Like the wood chip pellet machine for sale, they offer energy-saving, eco-friendly and highly efficient performance. We are committed to providing you with premium pellet production in the long term.

EFB Pellet Machine

It features a robust pelletizing system for processing hard-shelled materials into pellets.

rice husk pellet machine

This machine produces both highly calorific clean fuel and high-quality animal feed.

hay pellet machine

Our practical hay pellet machines can produce premium livestock feed and fuel pellets.

alfalfa pellet machine

Our alfalfa pellet machine is ideal for meeting your high-standard feed requirements.

Corn stalk pellet machine

We offer efficient corn stalk pellet machines that produce high calorific fuel pellets.

Frequently Asked Questions

We have extensive experience in serving clients worldwide. Accordingly, we understand the concerns you may have when selecting wood chip pellet machine. We have compiled answers to the following frequently asked questions, which we hope will be helpful. If you have any further questions, please do not hesitate to contact us.

–

What factors should you consider when selecting a wood chip pellet maker?

Your choice should be based on the condition of the raw material, your production capacity requirements and your budget. Our equipment can pelletize a wide range of wood materials. Under normal processing conditions, it produces consistent, high-quality results over extended periods.

Furthermore, the price of wood pelletizer is directly correlated with their production capacity. You can choose an appropriate capacity according to production scale.

If your budget allows, we recommend choosing high-efficiency industrial-grade equipment. We can provide tailored recommendations for suitable machines based on your specific needs.

–

What types of timber are suitable for wood pellet production?

Various types of timber can be used to manufacture wood pellets. However, they must possess suitable pelletization properties and moisture content. For raw materials such as logs, branches and bark, efficient crushing and drying processes are required.

If your raw material is waste wood, impurities must also be removed. We offer a range of wood crushing, cleaning and drying equipment. Our crusher can also be fitted with magnetic plates to capture ferrous contaminants.

–

What other biomass materials can our wood chip pellet machine process?

This equipment is a versatile industrial-grade wood pellet mill. As well as producing pellets from various types of timber, it can also process other types of biomass. These include crop husks and fruit shells. Each pellet meets the highest market standards.

In addition, we offer customized solutions for other biomass pellet machines. These include peanut shell pellet machine, sunflower shell pellet machine, cassava pellet machine, bamboo pellet machine and much more. (View YouTube)

–

Are wood chip pellet making machines expensive to invest in?

We supply commercial wood pellet makers. The investment cost depends on the production capacity. All of our models offer excellent pelletizing capability and the same energy-saving advantages.

We recommend you select based on your production scale. Lower-capacity wood chip pelletizer start from several thousand dollars. If you require a specific quotation, please do not hesitate to contact us.

–

What maintenance does a wood chip pellet machine require?

Our machines feature a simple design for easy maintenance. We suggest regularly checking key components for wear, such as the ring die and roller system. Our global spare parts network ensures a reliable supply.

It is equally important to clean the equipment daily. We advice clearing residual material promptly after each use. Moreover, after prolonged operation, apply lubricating grease to critical areas. This will minimize subsequent wear. Please strictly adhere to the equipment maintenance manual for routine maintenance.