rice husk Pellet Plant

in Indonesia

Pellet Diameter:

6mm

Raw Material:

Rice husks, wood chips

Application:

Rice husk fuel pellet production

Project Name:

High-Quality rice husk Pellet plant in indonesia (Turnkey Project)

capacity:

1.8-2 T/H

Indonesia rice husk Pellet Market

Indonesia is a major rice-growing nation that produces large quantities of rice husk waste each year. However, producing rice husk pellets can reduce wastage of resources and pollution. The government provides policy support for rice husk pellet production. Meanwhile, international demand for them continues to grow. Overall, Indonesia has excellent market prospects for rice husk pellets.

Although the supply is increasing, high-quality pellets remain scarce. The most significant challenge in pellet production currently lies in low formation rates and insufficient compaction. This results in a low calorific value and poor durability of the fuel. Therefore, it is essential for rice husk pellet plants to possess advanced production line equipment, thereby achieving better investment returns.

This rice husk pellet plant in Indonesia specifically chose us for professional equipment and superior service system. This production line solution features an efficient pelletizing system and an energy-saving process segmentation. It enables our clients to produce compact, plump fuel with a high calorific value, providing them with enhanced economic benefits.

CLIENT PROJECT DETAILS

The client operates a small turnkey rice husk pellet plant Indonesia. They have extensive factory space and abundant supplies of rice husks. Therefore, they wanted to invest in a production line to manufacture high-quality rice husk fuel. After an on-site visit and detailed discussions, the client selected our turnkey project.

Our engineering team conducted meticulous research and planning, followed by on-site construction and commissioning, to successfully deliver an ideal production line for the client. This line has now been operating smoothly for three years, producing rice husk pellets that significantly exceed market averages. The rice husk pellet plant in Indonesia has achieved an excellent return on investment.

For this project, the source of the rice husk feedstock is processing plant waste, which contains minor impurities of metal and sand. To ensure its cleanliness, we supplied a cylindrical primary cleaner and a suspended magnetic separator.

The client required 6 mm diameter rice husk fuel pellets, primarily for use in commercial and residential heating systems. Our pellet mill features an innovative ring die and roller system that can produce compact, fine pellets.

Solutions to Production Issues

In this project of rice husk pellet plant in Indonesia, we successfully overcame several challenges encountered during the construction of the production line and manufacturing operations. These included optimizing the layout of the equipment, improving the formation rates of rice husk pellets, and conducting worker training programs.

These are also common production issues that most rice husk pellet plants experience.

Many manufacturers have long struggled to achieve high pellet formation rates with rice husk. Our rice husk pellet mill boasts advanced granulation capabilities. Its dual-roll system provides powerful compression to significantly enhance the efficiency of pellet formation.

An unstable pellet structure leads directly to transportation losses and reduced storage life. To address this issue, we have incorporated a pellet cooling section. This ensures that rice husk pellets rapidly achieve a stable structure, making them easier to transport and store.

This project has a substantial engineering component, and the layout of the equipment is a key consideration. Our experienced engineers have designed a multi-level production line. This design saves space and enables more streamlined and efficient production.

However, workers at the rice husk pellet factory Indonesia lacked a basic understanding of production line operations. Therefore, we provided them with operational training to help them get up to speed more quickly. It covered topics such as equipment usage and daily maintenance.

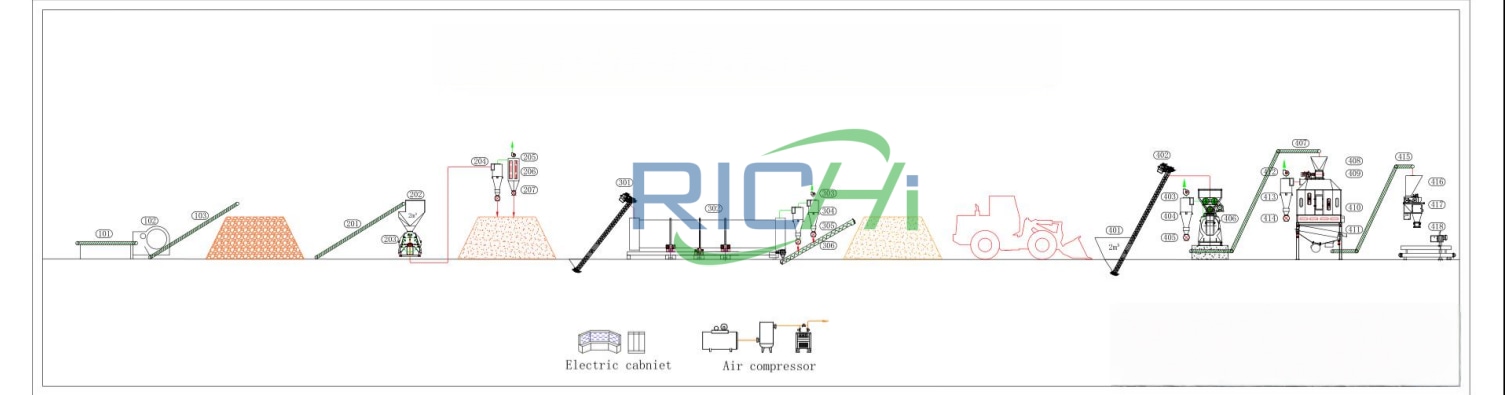

Process Design for the rice husk pellet plant in indonesia:

To meet the demand for efficient production processes and high-quality pellets, we have designed specialized solutions. This production line features scientifically divided process sections, and each section is equipped with robust machinery and auxiliary systems. This design is also ideal for other rice husk pellet plants with similar requirements.

01

Cleaning

Rice husks often contain impurities such as iron filings, sand, stones and plastic. These can damage equipment and affect pellets quality. Therefore, we have designed this processing stage to clean the raw materials.

02

drying

Rice husks have excellent moisture-absorbing properties, which can make large stockpiles prone to dampness. We provide a high-capacity drying drum to ensure the optimal moisture levels required for granulation.

03

Pelletizing

This section is equipped with an efficient rice husk pellet machine with a production capacity of 1.8–2.0 T/H. It can combine loose rice husks and wood chips to create hard, uniform rice husk pellets with high calorific value.

04

cooling

This section is equipped with a counterflow cooler to rapidly stabilize the pellet structure. This quickly reduces the temperature of rice husk pellets to ambient levels, facilitating packaging, transportation and extended storage.

05

screening

The screening section accurately separates standard-sized rice husk pellets to ensure uniform specifications. It also removes other materials for secondary granulation, thereby reducing raw material costs.

06

Packaging

We provide a fully automated pellet packaging scale for this section. This ensures consistent packaging specifications while reducing labor costs. A finished product bin with a 2m³ capacity is also integrated for a smooth transition.

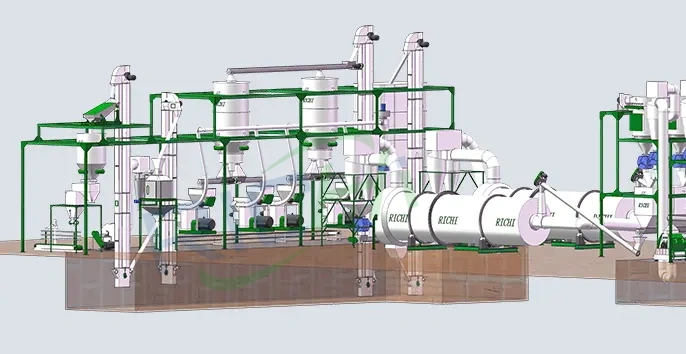

Configuration for this project

This project of rice husk pellet plant in Indonesia features energy-efficient production equipment and user-friendly auxiliary devices. Every piece of equipment has a meticulous design and undergoes rigorous testing. Our engineers will carry out on-site installation and commissioning to ensure optimal production performance.

01

Cleaning System

This cleaning device is a cylindrical primary screen. It can remove impurities, such as stones and sand, from husk materials. When used alongside a magnetic separator, they work together to effectively clean rice husk material.

02

Drying System

The high-capacity drying drum has a dual-barrel design and internal spiral agitator plates, which work together to rapidly and evenly dry rice husks. An external thermometer allows you to monitor and control drying temperatures in real time.

03

Pelletizing System

The high-capacity rice husk pellet machine provide consistently produces premium pellets over the long term. It is constructed from food-grade stainless steel and alloys, offering exceptional wear resistance and an extended service life.

04

cooling System

This counterflow cooler reduces the temperature of the pellets by circulating cold air and using convection. Its large capacity enables it to cool more pellets at once while providing energy-saving and eco-friendly benefits.

05

Screening System

The vibrating screen uses high-frequency vibration to separate pellets precisely. Its compact and flexible design allows for the simultaneous sorting of two pellet specifications while facilitating maintenance.

06

Packaging System

This fully automated packaging scale performs weighing and bagging tasks independently. It ensures consistent packaging specifications while reducing labor costs. The project utilizes heat-sealed packaging.

Since commencing operations in 2022, this production line has consistently delivered high-quality pellet products. Throughout this period, we have maintained a solid partnership with the rice husk pellet factory Indonesia. For example, we have provided various forms of technical support and ensured the rapid supply of spare parts.

For this turnkey rice husk pellet plant Indonesia, we provided our client with comprehensive services, including pre-sales consultation, exclusive customization, post-sales follow-up and ongoing support. As an equipment manufacturer with over three decades of industry experience, we operate large-scale manufacturing facilities capable of delivering solutions tailored to all your production needs.

RICHI Services

Through years of customer service, RICHI Machinery has developed a comprehensive service system. This includes end-to-end solutions from equipment consultation and project planning to construction, worker training and so on. Just as we do for this rice husk pellet plant in Indonesia, we provide optimal support for every pellet manufacturer.

Customized Solutions

RICHI has extensive experience in customer service. We can provide customized design solutions for rice husk pellet production. Whether you require customization of a single machine or of an entire production line, we will ensure that your actual production needs are met.

Production Line Solution

We provide professional rice husk pelletizers and production line solutions. They feature energy-efficient designs which achieve high forming rates and meet high quality pellet needs. By choosing our turnkey solutions, you can maximize your return on investment in the shortest possible time. (View YouTube)

One-Stop Service

All of our production equipment comes with a one-year warranty. We also have a global spare parts network, ensuring the rapid delivery of components such as ring dies and press rolls, which are prone to wear and tear. We also offer long-term technical guidance. You can contact us at any time.

Professional Manufacturer

RICHI operates large-scale, professional manufacturing plants. Each equipment that we deliver is meticulously designed and rigorously tested. To date, we have successfully completed over 2,000 outstanding pellet production projects worldwide. Partner with us to propel the growth of your rice husk pellet plant.

Other Husk Pellet Production Line Solutions

In addition to the rice husk pellet plant in Indonesia, we have provided high-quality production solutions for clients worldwide. As well as rice husk pellet production lines, we offer solutions for other types of husks, such as peanut shells, sunflower seed husks and walnut shells. Please feel free to contact us if you would like further information.

rice husk Pellet Plant solution

This production line can process loose rice husks into hard, compact rice husk pellets. It produces high-quality pellets for a variety of applications.

Sunflower Seed husk Pellet Production Line

It can efficiently process sunflower seed shells and produce pellets of various diameters and lengths.

Coconut Shell Pellet Production Line

It can crush hard coconut shells into a fine powder and process them into compact, plump pellets.

Cottonseed husk Pellet Production Line

This production line efficiently turns cottonseed hulls into pellets for use as fuel, organic fertilizer and others.

peanut shell Pellet Production Line

It can turn fluffy peanut shells into high-density pellets that can serve as fuel or agricultural substrates.