Husk Pellet Production Line

Our husk pellet production line have low raw material costs and a variety of applications. It can provide clean, low-cost fuel and ideal animal feed. The compact pellet structure also exhibits excellent water absorption, making it ideal for animal bedding and soil-improving fertilizers. We provide cost-effective, high-yield husk pellet production solutions.

BEST SOLUTION FOR HUSK PELLET PRODUCTION LINE

With over three decades of industry experience, we have become a leading manufacturer of pellet equipment. Therefore, we can offer you the optimal solution for husk pellet. Thanks to the professional technical team and large-scale manufacturing plant, we can deliver highly efficient equipment for clients.

In order to meet a range of output requirements, we offer husk pellet production lines with capacities ranging from 0.6 to 100 T/H. Our comprehensive range includes small, medium and large-scale production equipment to fulfill all your capacity requirements.

This meticulously designed processing lines can create denser husk fuel pellets with a calorific value of up to 14 MJ/kg, equivalent to 35% of the calorific value of diesel fuel. Their high-density structure also delivers superior moisture absorption. Our ring die pelletizers maximize raw material utilization, achieving higher output and quality standards.

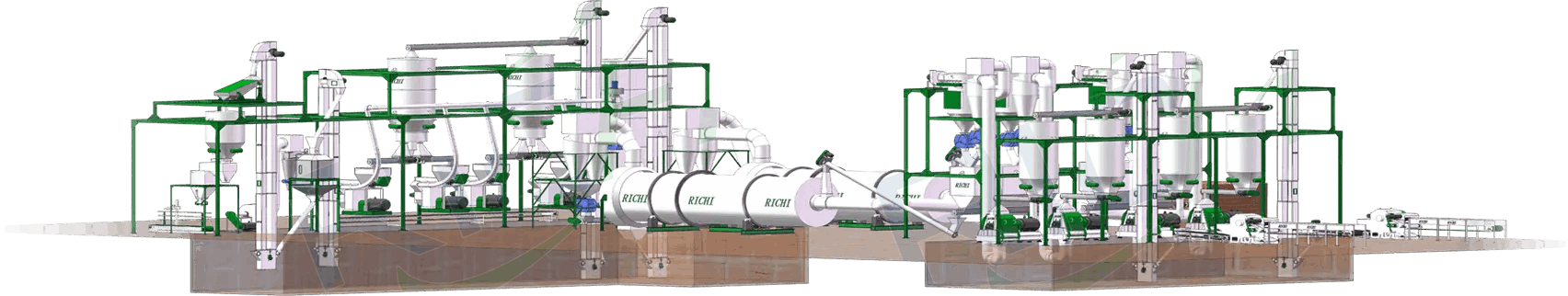

Complete process flow

Below are the six fundamental processes of this line.

Crushing

Drying

Pelletizing

Cooling

Screening

Packaging

WHAT KIND OF HUSK pellet PRODUCTION LINE DO YOU WANT?

Husk pellets represent a cost-effective and environmentally sustainable form of biomass pellet, making them suitable for a wide range of industrial applications, including husk pellet plant, power generation and animal husbandry. Whatever your application, our husk pellet production solution also offers seamless compatibility.

Process Flow of Husk Pellet Production Line

Leveraging years of industry R&D experience and user feedback, we have scientifically divided the husk pellet processing line into specialized modules. By optimizing the equipment and adhering to stricter production standards, we can ensure more stable and efficient husk pellet production. This approach meets your dual requirements for output and quality.

01

Husk Screening Stage

Many husks that have been dehusked by machine contain impurities, such as plastic and iron filings. These impurities can compromise pellet quality and accelerate equipment wear. If your raw materials are similar, this screening stage can help remove the dust and other impurities.

02

Husk Crushing Stage

This stage processes coarse husks into finer material, making it highly suitable for handling mixed materials. While husks themselves may be small enough to be made into pellets, mixed straw materials often contain long fibres that are not suitable for direct pelletisation. Crushing ensures optimal pellet density and formation rates.

03

Husk Drying Stage

The moisture content of raw materials directly impacts the effectiveness of pelletisation. Therefore, we have designed a drying stage. Using an efficient drum dryer, you can reduce the moisture content of the raw materials to an ideal range of 15–18%. This results in a more compact structure of the finished pellets, further improving the formation rate.

04

Husk Pelletizing Stage

Our husk pellet machine uses a high-precision ring die design with optimized parameters to achieve a high compression ratio and ensure efficient pelletization. Under high-temperature and high-pressure conditions, the binding properties of the raw material are enhanced and output is increased due to the rapid activation of lignin.

05

Pellet Cooling Stage

Pellets processed through high-temperature steam compression remain hot, which poses a safety risk if they are packaged and transported directly. Their moist, soft texture also makes them susceptible to deterioration if stored improperly. Rapid cooling in this section preserves the structural integrity of the pellets, facilitates transportation and extends storage life.

06

Pellet Screening Stage

In order to ensure the uniform appearance and consistent quality of husk pellets, a screening process is incorporated. High-intensity vibrating screens separate the pellets into standard sizes to ensure high-quality output. Smaller particles and powder are screened out for re-pelletisation, thereby reducing material costs.

07

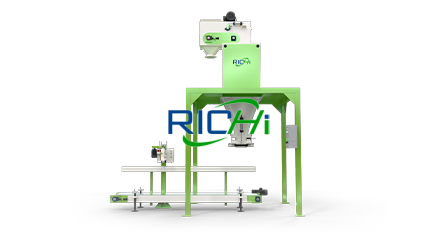

Product Packaging Stage

As the final stage of the production line, we use highly automated packaging equipment, from automatic weighing to rapid bagging. This significantly reduces labour costs and pellet loss, while ensuring consistent packaging that meets storage and sales standards.

The above outlines the main stages of the RICHI husk pellet production line. We also provide auxiliary equipment to further streamline the production process. If you are interested in the production line or would like to find out more about our equipment, please feel free to get in touch at any time.

Husk Pellets Produced By RICHI Equipment

These pellets are produced using our husk pellet production line equipment. Whether you need them for enhanced combustion efficiency or as animal feed and bedding, we can provide you with the ideal results. By choosing our production line solution, you can produce such high-quality husk pellets.

Rice husk pellets

Rice husks generally have low density and cannot burn efficiently. Pellets processed through the RICHI husk pellet production line measure 8-10 millimetres in diameter and are densely compacted, making them easier to ignite. Additionally, the ash content after combustion is reduced to 6-7%, further mitigating environmental pollution.

Sunflower husk pellets

Sunflower husks are prevalent agricultural byproducts with multiple applications. However, their lightweight nature presents a challenge in effective utilization. The pellets produced by our equipment are plump and glossy, with a calorific value of 16-17 GJ/MT. They serve as a highly competitive alternative to wood pellets.

peanut husk pellets

Some husk pellet raw materials, such as peanut shells, contain relatively long fibers and a low moisture content, which can result in poor pelletization. Our husk production line includes high-performance crushing equipment and pelletizers. The peanut shell pellets have a smooth surface and dense texture, as well as excellent fire resistance.

Smooth husk pellets

Our production lines feature scientifically designed, robust equipment, enabling you to easily produce any type of pellets. These husk pellets have a uniform texture and stable structure, which maximizes the retention of raw material nutrients. They are an excellent choice for combustion, animal feed, and bedding applications.

Suitable Raw Materials of Husk Pellet Production Line

The primary raw materials employed in the production of husk pellets are agricultural waste products, including crop husks and other straw-based materials. You might also consider mixed formulations of raw materials. Our advanced equipment can produce husk pellets with various formulations, ensuring consistently superior quality output across different raw materials.

rice husks

Peanuts Shells

sunflower seed shells

palm shells

cashew shells

Cotton seed hulls

coconut husks

Soybeans Hulls

sugarcane bagasse

coffee husks

The above are the common raw materials of our production line solution. If you have similar materials or are looking for efficient, reliable production equipment, this husk pellet processing line is the best choice for you.

Customization of husk Pellet Production Line Capacity

We have designed production solutions with varying capacities to meet diverse manufacturing needs. This production line is suitable for industrial-grade husk pellet production with capacities ranging from 0.6 to 100 T/H. We also offer customization services and turnkey solutions.

0.6-100 T/H

Husk Pellet manufacturing Line

This production line is one of the most popular among customers, delivering consistent, high-quality pellets through constant and reliable performance. It is ideal for medium-sized biomass pellet plants or animal feed processing facilities, ensuring high output and excellent economic returns.

0.6-1 T/H

1-2 T/H

3-4 T/H

5-6 T/H

7-8 T/H

10 T/H

8-12 T/H

15-20 T/H

20-40 T/H

Equipment on Husk Pellet Production Line

Material Screening Machine

RICHI screening process employs a high-efficiency cleaning screen to swiftly and accurately remove impurities such as stones, metal, and others. This process guarantees the purity and high quality of husk pellets, while also protecting other equipment from wear and tear.

Raw Material Crusher

Our innovative crusher can finely pulverize high-fiber and hard-shelled components within raw materials. The resulting material, reduced to 3-5 millimeters, can significantly enhance the uniformity and smoothness of the husk pellets.

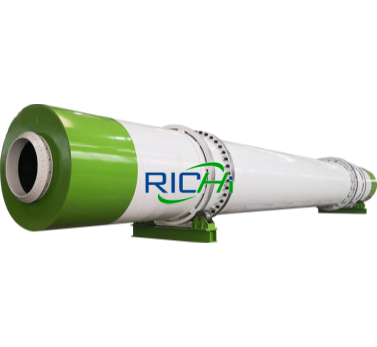

Drum Dryer

The drum dryer uses airflow to rotate materials within the drum, ensuring thorough and uniform drying. Featuring an innovative dual-barrel design, it maintains stable internal temperatures for highly efficient drying. It allows flexible adjustment of drying time.

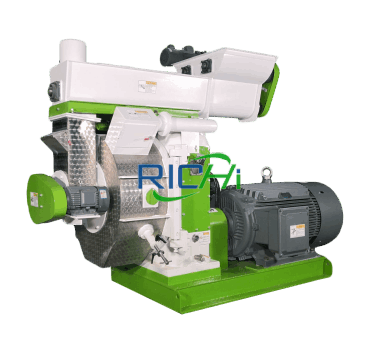

Husk Pellet Machine

The pellet machine is equipped with anti-blocking devices to effectively enhance the production rates. The innovative ring die utilizes the more wear-resistant alloy steel 42 CrMo. For feed production, we incorporate a conditioner to improve material gelatinization and palatability.

Counterflow Cooler

RICHI cooler features an enlarged capacity design. Utilizing counterflow convection cooling achieves rapid pellet temperature reduction. This enables pellets to set quickly, ensuring a smooth surface and promoting long-term structural stability.

Vibrating Screen & Bagging Scale

The screening and weighing system works in harmony to achieve rapid and precise particle sorting and packaging, ensuring consistent finished product quality. They can lead to a significant reduction in material and labour costs.

These husk pellet production equipment features high efficiency and stability, as well as a high level of automation. This provides you with reliable and flexible production. We prioritize outstanding equipment performance and excellent adaptability, enabling seamless integration into various biomass pellet production processes. Paired with our flexible and convenient auxiliary systems, this ensures that you maximize your return on investment.

GLOBAL CASES

We have provided premium husk pellet production solutions to customers worldwide to date. We have a deep understanding of each customer’s needs and expectations, ensuring our production equipment aligns perfectly with your requirements.

CUSTOMER REVIEWS

For years, we have focused on the innovative research and development of husk pellet equipment. Furthermore, we are committed to providing customers with reliable and durable production line solutions. Below are reviews from our global customers. You can learn more about our equipment and services through these testimonials.

Click to chat with us online

VIDEO TAKES YOU INTO

HUSK PELLET PRODUCTION LINE

Our industrial-grade production line solutions have earned recognition from customers worldwide. Below are examples of their actual operation across the globe, including various types of pellet production and specific pellet demonstrations. Through these, you can gain a deeper understanding of our solutions.

5 T/H Sunflower Meal Pellet Production Line

Husk Production Line Crushing and Pelletizing Section

Husk Pellet Production Line

Frequently Asked Questions

We possess extensive experience in customer service. Therefore, we fully understand your concerns when selecting a straw pellet production solution. We have compiled a Q&A to address these issues, covering topics such as raw material suitability, equipment maintenance and after-sales service. Should you have similar concerns, the answers you need can be found below.

What conditions must raw materials meet for producing husk pellets?

+

There are three criteria that must be satisfied: appropriate moisture content, cleanliness and a small particle size. Our husk pellet production line can perfectly address these issues.

● The moisture content should be around 15% for husk feedstock. Excessive moisture causes a loose pellet structure and poor formation, while insufficient moisture reduces binding strength and similarly impacts yield.

● You raw materials must be free of impurities such as metal or stones to ensure clean and high-quality pellets while preventing wear and tear to machinery.

● If the fibers in the husk material are excessively long or large, pre-processing through crushing and screening is usually required. Crushing ensures pellet uniformity and a smooth production flow.

We also offer pellet production lines suitable for high-fiber shells, such as the EFB pellet production line. For pellet solutions involving other crops and fruit shells, please feel free to contact us anytime.

What are the key parameters affecting pellet formation and quality?

+

The conditioning process and the ring die compression ratio are both critical parameters that influence final pellet quality.

The conditioning process refers to the preliminary treatment of the material to achieve the best rates of pellet formation.

Furthermore, it is essential to control the ring die compression ratio correctly, based on the raw material characteristics and pellet specifications. Incorrect equipment parameters have the potential to impact pellet structure and output.

What standards do the products from husk pellet production line comply with?

+

Particle Durability Index (PDI): This assesses the structural integrity of the pellets, their resistance to breakage and their density.

Moisture content: Husk pellets typically require a moisture content below 12% to facilitate optimal storage and transportation.

For specific durability and moisture content benchmarks, refer to the target market’s industry standards or internationally recognized specifications.

Regardless of the standard, our husk pellet production line delivers flawless results. (View YouTube)

What are the key points for daily maintenance of husk pellet production line equipment?

+

This production line incorporates numerous pieces of equipment. Please ensure you follow the maintenance instructions in the equipment manual strictly. There are several key maintenance points to consider.

If your equipment requires extended operation, please apply grease regularly. This helps reduce wear and tear on the machinery. However, you must still inspect the molds and pressure rollers periodically and promptly replace severely worn components.

Routine cleaning is equally important. Residual materials must be removed promptly to prevent corrosion. Proper maintenance not only ensures long-term stable operation but also minimizes equipment wear, thereby significantly reducing the risk of production downtime.

When selecting equipment suppliers, we recommend evaluating the following aspects:

+

Industry experience: RICHI Machinery has accumulated over 30 years of experience in the industry. We can provide an efficient husk pellet production line. We have successfully served clients in over 100 countries and regions worldwide, receiving consistently high praise.

Customization capabilities: Please confirm whether they have the capacity to modify production lines according to your raw materials, production requirements and operational needs. Our technical team is proud to deliver truly bespoke production solutions.

Equipment technology: Please evaluate the automation levels, innovative design features and component quality.

After-sales support: We provide dual-track services, combining online and offline solutions, as well as a global spare parts network. These services ensure you receive satisfactory support throughout every production phase.