eFB pellet Machine

The EFB pellet machine is a specialized device used for producing pellets. Thanks to the innovative structural design, it can convert high-fiber empty fruit bunches into high-calorific-value pellet fuel. Contact us to find the perfect equipment for your EFB pellet production needs.

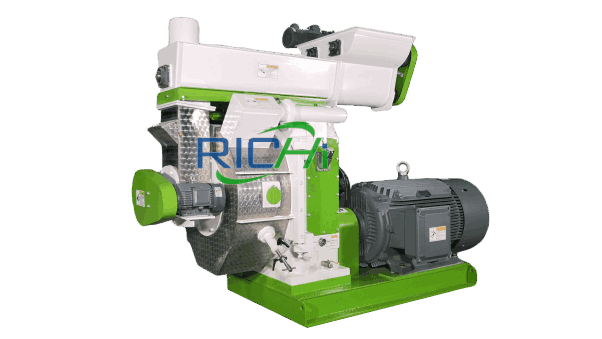

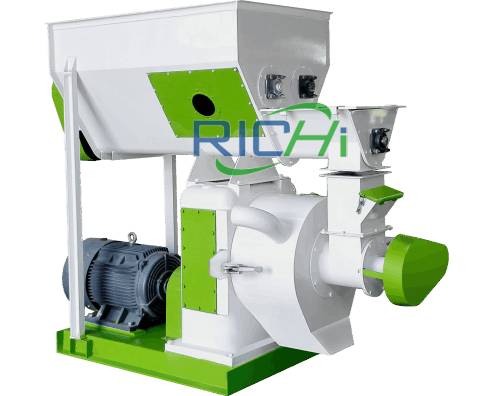

Professional EFB Pellet Machine

RICHI EFB pelletizer boasts exceptional pelletizing capability, producing densely compacted pellets. It not only extends the fuel’s combustion duration, but also facilitates transportation and storage, ensuring greater durability. Thus, it is an environmentally beneficial pelletizing solution.

Empty fruit bunches provide an abundant supply of raw material, offering seven times the volume of natural timber. Our innovative EFB pellet mill transforms these into high-quality pellet fuel. This enhances thermal efficiency while avoiding the environmental pollution caused by direct combustion.

Empty fruit bunches are made up mainly of cellulose, hemicellulose and lignin, with a moisture content of around 65%. Our pelletizer uses a high-temperature process where the steam environment maximizes the binding properties of lignin. This results in higher pellet formation rates and increased production efficiency.

How Does an EFB Pellet Machine Operate?

Each EFB pellet mill is the result of years of innovative research and development, as well as rigorous testing. We are committed to providing you with reliable, high-performance pellet machines.

Our pelletisers have been meticulously engineered to deliver superior pelletisation results.

Due to the substantial size, empty fruit bunches present challenges to direct pelletisation. Therefore, it is essential that the feedstock entering the pelletiser has been crushed first. The standard particle size should be 3–5 mm, or reduced to a finer powder. To ensure smooth progression of processed material into the pelletisation stage, the feed inlet incorporates an arch-breaking device.

Here, the conditioning effect of high-temperature steam fully releases the lignin within the material. Once the desired viscosity level is reached, the material enters the pelletising chamber. A forced feeding device at the inlet pushes any accumulated material into the chamber. The material is then efficiently fed into the die through the powerful compression of the dual roller system.

Thanks to multiple innovative improvements, the mould now produces the desired diameter for EFB pellets. The roller system continuously compresses cylindrical raw material, extruding it through the aperture. At this stage, blades inside the housing start to operate and cut the material into uniformly sized pellets.

These pellets are then discharged via the outlet beneath the pelletizing chamber under the force of gravity. You may then inspect the pellets to ensure they meet your requirements. If further refinement is necessary, the pellets can be reintroduced through the feed inlet above the pelletizing chamber for further processing.

Innovative Design

We have incorporated numerous technological innovations into the design and manufacturing of EFB pellet machine. Furthermore, we have conducted extensive customer research to tailor the manufacturing process, ensuring it meets clients’ actual production requirements. Consequently, we now have the ability to provide you with highly efficient EFB pelletizer.

In addition to the scientifically informed innovative design, we offer EFB pellet making machines with a range of production capacities to accommodate your needs. If you require customization services, we can also provide dedicated solutions.

01

Feed Inlet

Featuring an enlarged, widened design and an arch-breaking device, it enables the simultaneous feeding of larger quantities of raw materials.

02

Pelletizing chamber

With forced feeding and specially designed feed and discharge ports, it allows for manual feeding and observation of the pelletising process when required.

03

Ring Die Mould

The optimised ring die provides the ideal compression ratio for processing a variety of complex materials and completing challenging granulation tasks.

04

Press Roll System

The dual-roll design and increased working area enhance the compression force on the material, resulting in a more compact pellet structure.

05

Heat Dissipation System

An exhaust vent and fan are fitted above the chamber to promptly discharge high-temperature vapour, thereby reducing the temperature of the equipment.

06

Power System

Multiple industrial-grade Siemens motors are installed throughout the unit, ensuring efficient and stable operation at every stage of the granulation process.

Parameters of EFB Pellet Machine

| Model | MZLH320 | MZLH350 | MZLH420 | MZLH520 | MZLH678 | MZLH768 |

| Main Motor Power(kw) | 22 | 37 | 90 | 132 | 185 | 250 |

| Breaker Feeder Power(kw) | 2.2 | 2.2 | 3 | 3 | 3 | 4 |

| Forced Feeder Power(kw) | 0.75 | 0.75 | 1.5 | 1.5 | 1.5 | 1.5 |

| Ring Die Inner Diameter(mm) | 320 | 350 | 420 | 520 | 673 | 762 |

| Pellet Diameter(mm) | 4-12 | |||||

| Capacity(T/H) | 0.5-0.6 | 1.0-1.2 | 1.8-2.0 | 2.8-3.0 | 4-5 | 6-8 |

The above details the standard operating power and production capacity of the EFB pellet mill. If you require models with different output capacities or higher pellet specifications, we can design and manufacture customized solutions to meet your needs. Please contact us to discuss your production solution.

Advantages of eFB Pellet Machine

Our EFB pelletizer not only produces pellets efficiently, but also offers multiple advantages. Following years of market validation and testing through global customer applications, it has been proven to deliver tangible benefits, such as energy efficiency, environmental friendliness, an extended service life and high operational safety.

Applications of EFB Pellet Machine

Our empty fruit bunch pellet machine is highly versatile and can produce pellets from a variety of agricultural husks and fruit shells. Regardless of your feedstock, it delivers flawless results.

Processable Raw Materials

The high fibre content of empty fruit bunches enables our equipment to pelletise other high-fibre materials, such as palm shells, betel nut shells, coconut shells and other biomass husks. Below are some of the most common feedstocks for pellet production. We also offer customised equipment solutions for producing pellets from other shell materials. Please feel free to enquire at any time.

Empty Fruit Bunch

Palm Kernel Shell

Areca Nut Shell

Coconut Husk

Walnut Shell

Peanut Shell

The Perfect Pellets

Empty fruit bunches usually has a relatively light texture and high fiber content, which makes it difficult to pelletize. However, this husk pellet machine for EFB has a superior structural design that effortlessly handles the pelletization of various husk pellets.

The resulting pellets have a uniform structure and compact texture thanks to the robust pelletizing system. This not only facilitates storage, but also extends their combustion duration. Whatever your specific pellet production requirements, it delivers consistent quality every time.

Below are various types of pellets produced using our EFB pellet mill. If you are interested in purchasing an excellent pelletizer, please feel free to contact us at any time.

Empty Fruit Bunch Pellets

Betel Nut Shell Pellets

Coconut Shell Pellets

Walnut Shell Pellets

Peanut Shell Pellets

Coffee Husk Pellets

Rice Husk Pellets

Sunflower Seed Husk Pellets

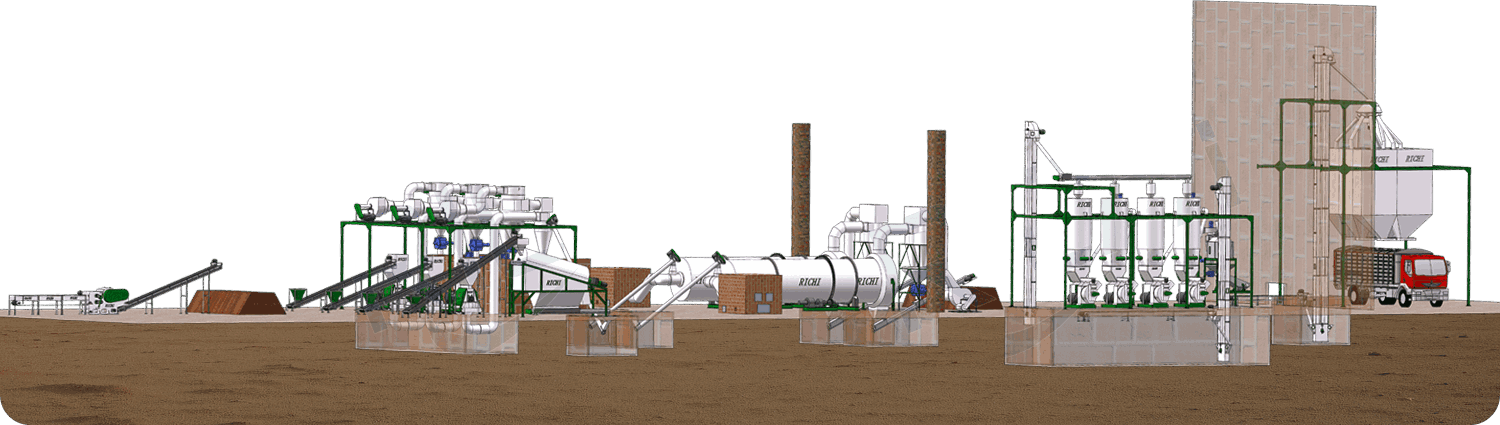

eFB Pellet Production Line

EFB pellet machine is the core piece of equipment in husk pellet production line for EFB. We offer comprehensive production line solutions with throughput capacities ranging from 0.6 to 40 T/H, capable of efficiently processing diverse raw materials. This production line delivers stable and consistent output of high-quality pellets through scientifically organised process stages. We also provide turnkey production solutions tailored to your needs.

01

Crushing

Empty fruit bunches are very bulky, which makes direct pelletisation impractical. Consequently, we have added a dedicated crushing stage. This stage uses high-efficiency crushers to reduce the material to fine particles measuring 3–5 mm, which facilitates subsequent pellet formation.

02

Drying

Fresh EFB contains around 65% moisture. Direct pelletisation would be ineffective due to poor formation. Consequently, this stage incorporates a large-capacity drying drum. This can dry large quantities of material at once, controlling the moisture content to the ideal range of 15-18%.

03

Pelletizing

As the core equipment in this production line, our EFB pellet mill boasts exceptional performance. We have enhanced its ring die and roller system. So that, when combined with the action of high-temperature steam at 80°C, it can produce premium-quality pellets that meet the highest standards.

04

Cooling

Pellets manufactured in a high-temperature steam environment are usually moist and soft. Our range of cooling units rapidly reduces their temperature to ambient levels. This preserves the optimal structure of the pellets, facilitates packaging and transport, and minimises the risk of deterioration.

05

Screening

A range of screening units designed for this stage are available. Screening retains standard-sized finished pellets to ensure marketability. Fines can be re-pelletised to conserve material costs. The vibrating screens can be integrated with coolers to save space.

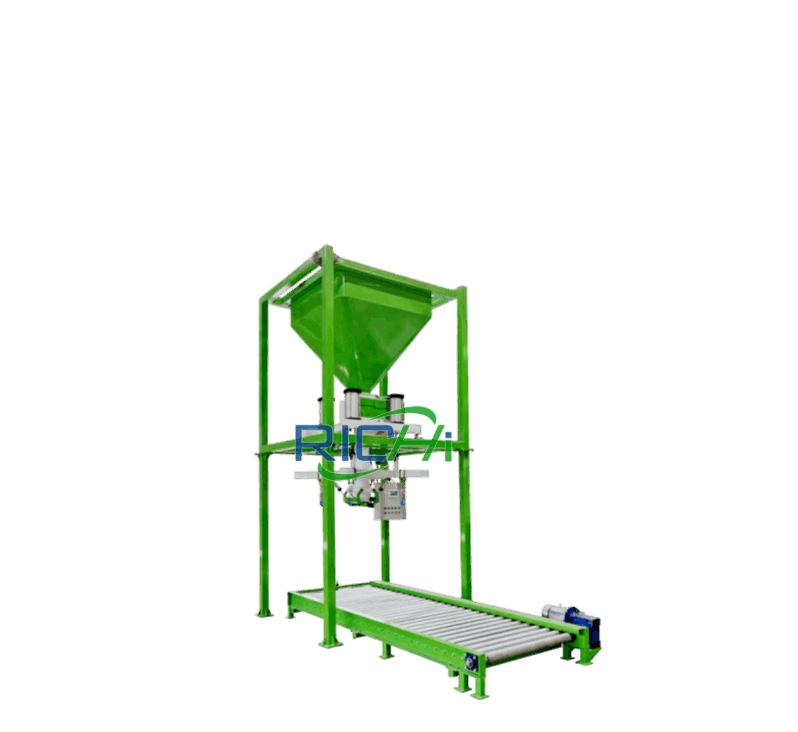

06

Packaging

You can select packaging scales with varying levels of automation to suit your needs. Our fully automated scales can weigh and package items independently, ensuring consistent specifications and reducing labour costs. Packaging options include heat-sealed pouches or conventional bags.

Application Scenarios

Our EFB pellet machine has multiple applications. Firstly, its exceptional pelletizing capability offers significant convenience to oil palm plantations and processing enterprises. This enables the utilization and enhancement of the value of EFB. Secondly, it produces high-quality fuel that is highly competitive in the market, thereby earning the trust of numerous biomass pellet manufacturers.

We offer free consultations on production solutions and equipment around the clock.

We also provide EFB pellet project planning and production line turnkey solutions.

Biomass Fuel Manufacturing Plants

Oil Palm Processing Enterprises

Rapid Customisation Services

High Return on Investment

Global Projects

Thanks to advanced production capabilities and excellent customer service, our EFB pellet making machines have been successfully sold in numerous countries and regions worldwide. Whether you are looking to purchase a single unit or invest in a complete production line, we can provide the most satisfactory production solution for your needs.

EFB Pellet mill For Sale Malaysia

This client is an efb pellet plant in Malaysia that generates substantial by-products, including EFB and palm kernel shells. Our equipment efficiently processes these materials, producing pellet fuel.

EFB Pellet machine for Sale Thailand

This client operates extensive oil palm plantations and requires a machine to process substantial quantities of empty fruit bunches. We supplied a EFB pellet mill with a capacity of 2-3 T/H.

Indonesia EFB Pellet Manufacturing Plant

As a biomass pellet manufacturer, the client has access to large quantities of empty fruit bunches. We supplied a high-capacity pellet machine to produce premium-quality pellet fuel.

EFB Pellet press for Sale Papua New Guinea

They operate oil palm plantations with an ample supply of raw materials, requiring to process palm kernel shells, oil palm trunks and fronds. We supply pelletisers producing pellets with a diameter of 6–8 mm.

Nigeria EFB Pellet Production Project

Our client operates a biomass pellet making plant with abundant oil palm feedstock. The primary raw material consists of palm kernel shells blended with palm wood chips. They selected our efficient pellet mill alongside a complete pellet production line.

Ghana EFB Pellet Production Plant

The client’s existing palm efb pellet press machine struggled to meet daily production demands. Our EFB pellet mill delivers superior pelletization results and higher output, fulfilling the client’s production expectations.

EFB Pellet mill For Sale Côte d’Ivoire

In this project, our client has an oil mill with substantial waste empty fruit bunches. RICHI’s pelletiser produced high-quality fuel with a diameter of 8-10 mm, meeting efficient processing requirements.

Colombia EFB Pellet Project

This project utilises palm fronds, palm wood, and fruit shells as raw materials. We provided a complete production line solution, including efficient raw material crushing, drying equipment, pellet mills, and a pellet screening and packaging system.

Why Choose RICHI?

We are a leading brand in the manufacturing industry for pellet equipment.

RICHI Machinery was established in 1995, and we have remained dedicated to providing customers with the best pellet solutions. We are driven by customer satisfaction and are engaged in the research of pellet machinery. To date, we have successfully supplied high-quality EFB pellet machine to clients worldwide.

Drawing upon extensive customer service experience, we have a thorough understanding of your production needs and the challenges at every manufacturing stage. Consequently, we offer an integrated solution combining pre-sales and after-sales support to protect your EFB pellet production operations.

Our after-sales service includes a one-year warranty and a prompt response to any quality issues. To ensure rapid dispatch of components, we also maintain a global network of spare parts. If you encounter any production challenges, we will provide solutions to help you resume operations swiftly. We also offer the following services:

Free consultation Service

At RICHI, our experienced engineers and sales team are ready to provide free consultations for EFB pelletizer. We understand our clients’ production requirements and queries, so feel free to ask us any questions you have about the production solutions.

Customised Equipment Service

Should you have specific requirement for output and standard for pellets, we can provide tailored solutions to meet your needs. Our specialist technical team and large-scale manufacturing facilities can accommodate all your equipment needs.

Turnkey Production Solutions

Besides exceptional EFB pellet mill, our production line solutions have earned the trust and support of clients. Our turnkey solutions, in particular, offer complete service including project planning, construction, equipment installation and operator training.

Other Related Production Equipment

At RICHI, we have extensive experience in equipment research and development, supported by our large-scale manufacturing facilities. We supply advanced EFB pellet machine and produce equipment for processing raw materials, as well as pellet cooling units, screening systems and packaging systems. Whatever production solution you need, we can provide the ideal equipment.

Raw Material Crusher

It can pulverise large clusters of EFB into particles measuring 3–5 mm, thus facilitating granulation.

Drum Dryer

It can reduce the moisture content of fresh EFB material to an ideal range of 15–18%.

Cooling Machine

This machine rapidly cools EFB pellets to maintain optimal structure.

Packaging Scale

It provides fully automated weighing and uniform packaging. Packaging options include heat-sealed bags and conventional sacks.

Frequently Asked Questions

At RICHI, we have extensive experience in equipment research and development, supported by our large-scale manufacturing facilities. We supply specialized EFB pelletizer and raw material processing equipment, pellet cooling units, and screening and packaging systems. Whatever production solution you need, we can provide the ideal equipment.

–

Can the EFB pellet mill handle co-granulation with other raw materials?

Our EFB pellet mill is highly versatile and fully capable of processing mixed granulation with a variety of different raw materials. For example, you could combine EFB with wood chips and palm kernel shells, which is a common production ratio. Furthermore, our equipment allows for the co-granulation of empty fruit bunches and straw.

Blended pelletization can utilize the natural adhesive properties of the lignin present in different materials to enhance pellet formation rates. If required, our engineering team can provide suitable moulds and adjust the process parameters to match your specific raw materials.

–

Is the EFB pellet machine complicated to operate?

The innovative structural design of our equipment makes it user-friendly. It is not only easy to operate, but also facilitates subsequent maintenance and regular component replacement. Each unit is dispatched with a full instruction manual and video tutorials to help you quickly learn how to use it.

We also offer other user-friendly pelletizing equipment, such as peanut shell pellet machine, rice husk pellet machine, sawdust pellet machine, rice straw pellet machine, and more.

For production line projects, we send professional engineers to carry out on-site installation. They will verify equipment connections and conduct commissioning work. Once complete, they will provide operational training to ensure your subsequent production runs smoothly and efficiently.

–

What is involved in the daily maintenance of an EFB pellet mill? What is the service life of its key components?

This equipment has a scientifically designed structure that makes routine maintenance simple and convenient. Primary tasks include periodically lubricating critical areas and inspecting components for wear. The parts most susceptible to wear are the press rollers and ring die. These require regular observation and replacement based on operational frequency.

The service life of these parts depends on the abrasiveness of the raw material, how frequently it is used, and how it is maintained. Our ring die components are manufactured from corrosion-resistant alloy materials, thereby extending their operational lifespan. We operate a global spare parts network to ensure the rapid delivery of replacement components.

–

How are EFB pellet machines different from wood chip pellet machines?

We have adjusted the internal structure and pelletisation process of our equipment to accommodate differing feedstocks. EFB pellet mills are designed for high-fiber, low-lignin materials, while wood chip pellet mills are optimized for lignin-rich woody substrates and achieve higher natural formation rates.

Our EFB pellet mill has undergone specialized optimization to handle the challenge that long fibers in EFB present in terms of forming. For example, the forced feeding and arch-breaking systems have been reinforced and the die compression ratio enhanced. Using our equipment, you can achieve more efficient and stable production results.

–

What safety precautions should be observed when operating an EFB pellet machine?

It is essential to follow the operating manual for the equipment strictly. The following are key safety points:

Ensure that the raw materials are clean to prevent contaminants, such as metal or stones, from entering the pelletizing process and causing unnecessary wear to the equipment.

Before starting up, check that all components are securely fastened. Our equipment incorporates overload protection devices, so do not open the housing or rotate any moving parts during operation.

Should the EFB pellet mill exhibit abnormal vibration or noise while running, cease operation immediately and carry out an inspection. Before undertaking any inspection or maintenance work, ensure that the power supply has been safely disconnected. (View YouTube)