Alfalfa Pellet Machine For Sale

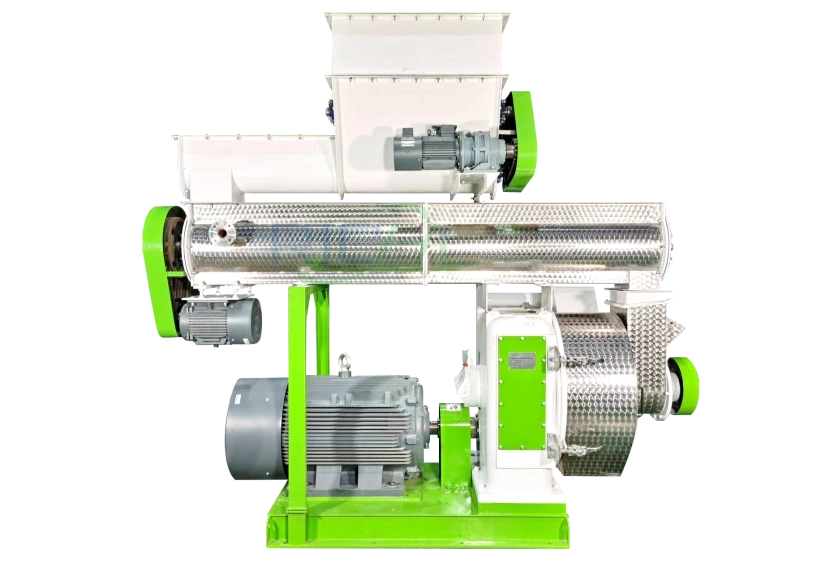

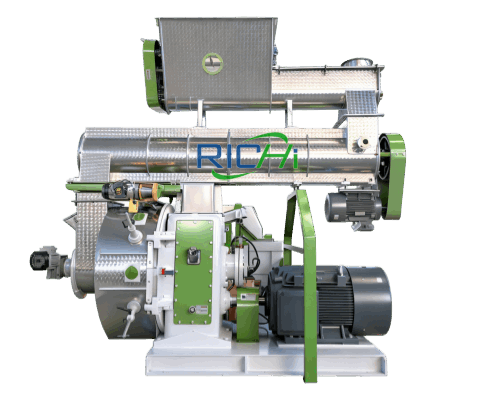

The alfalfa pellet machine for sale has multiple production capacities to meet a variety of needs. It can process different types of alfalfa grass into high-quality feed pellets. Contact us for customised equipment solutions.

Efficient Alfalfa Pellet Machine For Sale

RICHI alfalfa pelletizer are professional, industrial-grade equipment. They can effortlessly turn alfalfa hay, fresh alfalfa grass and alfalfa powder into pellets. The resulting pellets are plump and compact. Choose us for your ideal pellet production solution.

Alfalfa hay is rich in nutrients, including protein and dietary fiber. Our alfalfa pellet mill for sale is equipped with conditioner that optimally condition the raw material to preserve its nutritional structure. This ensures the pellets have superior palatability and enhanced digestibility.

However, alfalfa feedstock has a relatively light texture, which makes it difficult to guarantee consistent formation rates and output yields with traditional pellet mills. Our alfalfa pellet mill for sale is specifically engineered for lightweight materials. Its enlarged, widened structure and optimized pelletizing system ensure superior results.

Work Process Of Alfalfa Pellet Machine For Sale

Each pelletizer is specially designed to produce high-quality pellets consistently. Using a unique roller system and ring mold, it ensures highly efficient production of high-quality pellets.

We offer customizable alfalfa pelletizer, which meets your diverse production needs.

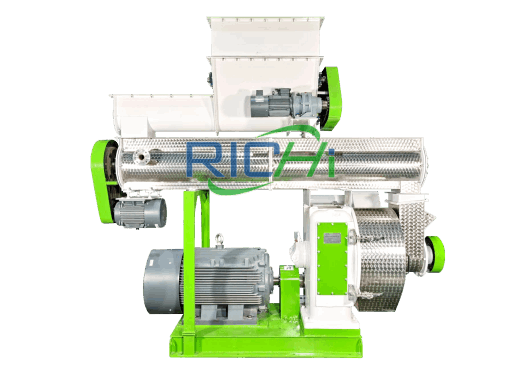

The materials have a high fiber content, which require pulverization before being fed into the pellet machine. After this, powdered material can proceed into the pelleting process. They first pass through a de-bridging device, which ensures smooth progression into the conditioner.

The conditioning temperature reaches 80–90°C, ensuring thorough gelatinisation of alfalfa forage. To prevent accumulation, a forced feeder conveys the gelatinised material into the pelletising chamber. With a powerful pressure exerted by the dual-roller system, the material is then extruded through the ring die apertures into pellets.

Finally, blades on the pellet chamber will cut the material into uniformly sized alfalfa pellets. These pellets then fall through the outlet beneath the pellet chamber by gravity. Freshly produced pellets are moist and soft. It is only after cooling to room temperature that the pellets achieve a stable structure.

Innovative Design

Drawing on our extensive experience in designing and manufacturing pelletising equipment, we offer advanced alfalfa pellet machine for sale. Our machine is designed to meet clients’ specific production needs. It can achieve highly efficient, modern pellet production.

In addition to the innovative structural design, this alfalfa pelleting machine is available across various production capacities. Boasting exceptional pelletizing performance, it meets the most stringent production standards.

Depending on your specific raw material ratios and production capacity needs, we can increase the number of conditioners. We can also provide more ring die apertures and make parameter adjustments.

01

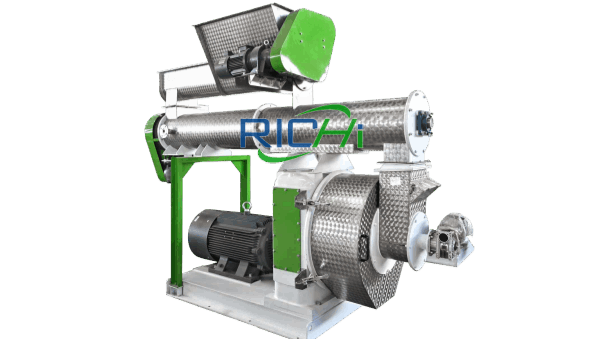

Feed Inlet

The enlarged feed inlet, combined with an arch-breaking feeder, enables the handling of greater quantities of material in a single batch.

02

conditioner

The upgraded conditioner has a wider design that improves material conditioning and increases the yield per unit of material.

03

Forced Feeder

This device propels material above the pellet chamber into the hopper, thereby accelerating production and minimising waste.

04

Ring Die Mold

The innovative, upgraded ring dies can be adapted to various raw materials, achieving optimum compression ratios. We offer ring dies in a range of sizes.

05

Dual-Roll System

The optimised dual-pressure roller structure and enlarged working area deliver enhanced compression effects and improved moulding efficiency.

06

Ventilation Outlet

Each alfalfa pellet mill for sale is fitted with a efficient heat dissipation system, ensuring timely expulsion of high-temperature steam.

Parameters of Alfalfa Pellet Machine

| Model | CZLH320 | CZLH350 | CZLH420 | CZLH520 | CZLH678 | CZLH768 |

| Main Motor Power(kw) | 22 | 37 | 90 | 132 | 185 | 250 |

| Breaker Feeder Power(kw) | 2.2 | 2.2 | 3 | 3 | 3 | 4 |

| Forced Feeder Power(kw) | 0.75 | 0.75 | 1.5 | 1.5 | 1.5 | 1.5 |

| Ring Die Inner Diameter(mm) | 320 | 350 | 420 | 520 | 673 | 762 |

| Pellet Diameter(mm) | 4-12 | |||||

| Capacity(T/H) | 0.5-0.6 | 1.0-1.2 | 1.8-2.0 | 2.8-3.0 | 4-5 | 6-8 |

The above details the specific parameters of RICHI alfalfa pellet machine for sale. You can choose the right model for your production capacity and pellet specifications. If you require other parameters, please contact us for customized solutions.

Advantages of Alfalfa Pellet Machine For Sale

We have extensive experience in manufacturing equipment and providing customer service. Consequently, our alfalfa pelletizer machine for sale offers advantages such as high efficiency, energy savings and safety, making it the ideal choice for you.

Applications of Alfalfa Pellet Machine

Our alfalfa pellet machine for sale is specifically designed for processing high-fiber materials. It has a high-efficiency pelletizing ability and can be used to produce various types of grass and straw pellets.

Processable Raw Materials

To handle the high fiber content of alfalfa, our equipment has undergone multiple structural optimizations. Consequently, it is also ideal for processing other high-fiber, lightweight materials. Please contact us for a bespoke equipment solution.

Alfalfa

Hemp

Clover

Ryegrass

Oat Grass

Straw

The Perfect Pellets

Our alfalfa grass pellet machine can produce grass pellets from a variety of raw materials. Regardless of the feedstock used, it consistently produce compact, well-formed pellets.

As well as producing standard alfalfa pellets, you can blend in appropriate proportions of straw or grains, optimising the nutritional composition to achieve superior feeding results.

Below are examples of high-quality grass pellets. Using our alfalfa pelletizer machine, you can also have such perfect pellet products.

Alfalfa Pellets

Clover Pellets

Oat Grass Pellets

Ryegrass Pellets

Hemp Pellets

Soybean Grass Pellets

Wheat Straw Pellets

Rice Straw Pellets

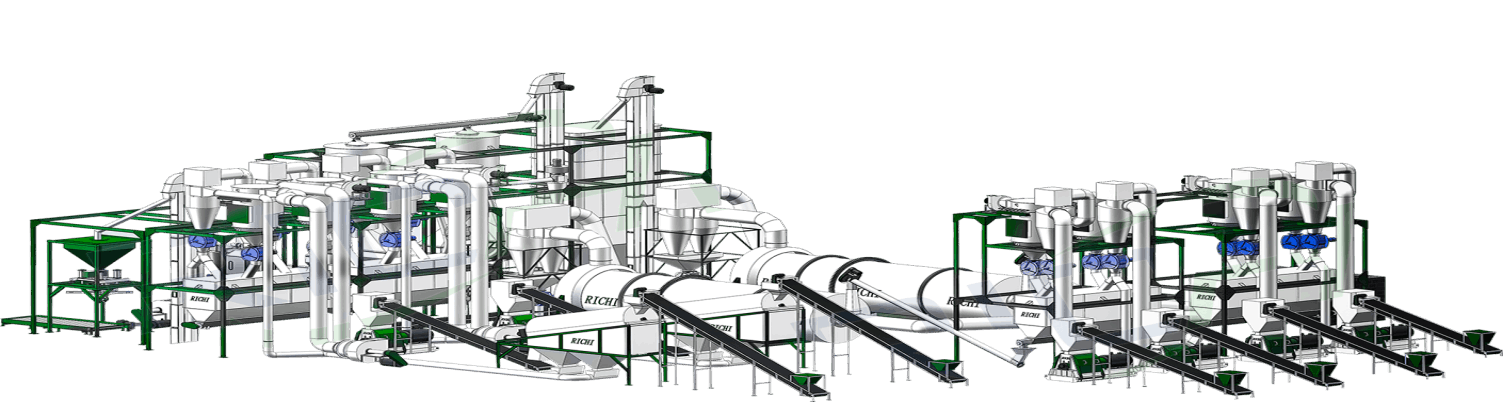

Alfalfa Pellet Production Line

Our alfalfa pelleting machine is the core piece of equipment in alfalfa pellet production line. We also offer comprehensive grass pellet production line equipment. These solutions feature scientifically segmented processing stages, with production capacities ranging from 0.5 to 40 T/H. We also provide turnkey solutions and customized services.

01

Crushing

Grass materials have a high fibre content, so need crushing to a powder for efficient pelletisation. This stage uses a forage crusher with a large capacity and a robust crushing system that can easily process different types of grass and straw.

02

Drying

This stage uses a large-capacity drying drum to reduce the moisture content of the raw materials to an optimal level of 18%. The dual-drum design incorporates internal spiral agitators to ensure rapid and uniform drying of the feedstock.

03

Pelletizing

The alfalfa pellet machine for sale can handle tasks of varying complexity. We adjust the number of conditioners and modify the dies according to your raw material. This ensures consistent production of flawless pellets.

04

Cooling

Freshly produced pellets have a relatively moist and soft structure. Consequently, this stage uses a counter-current cooler. It rapidly cools the surface of the pellets, preserving their optimal structure and enhancing stability.

05

Screening

The rotary grading screen is the standard equipment for this stage. It accurately separates standard pellets while removing fine particles, ensuring consistent pellet size and enabling secondary pelletisation of the material.

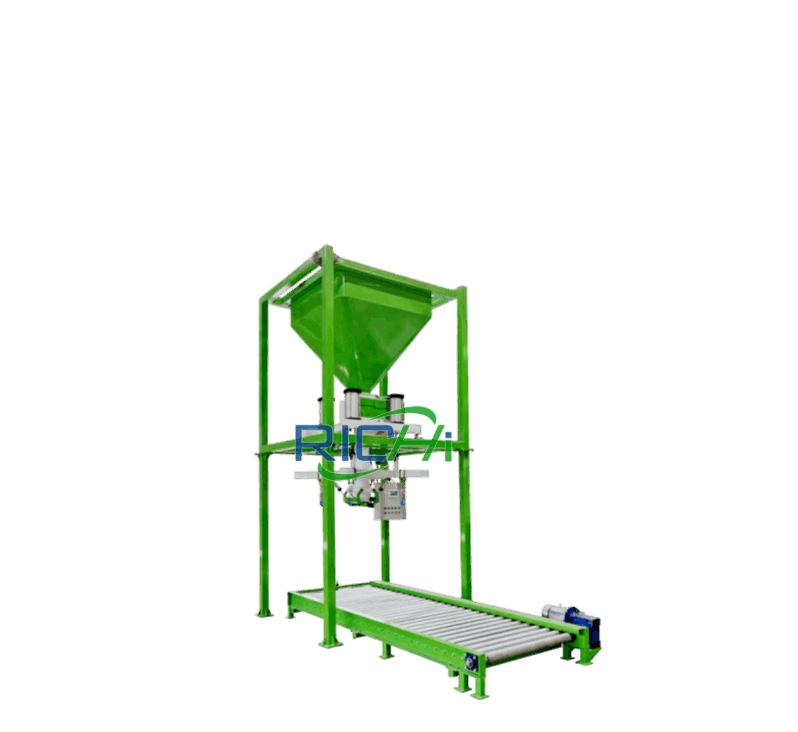

06

Packaging

We also supply packaging scales and heat-sealing machines with various levels of automation. The fully automatic scales enable automated weighing and packaging, ensuring consistent product specifications while reducing labour costs.

Application Scenarios

The alfalfa pellet machine for sale significantly compressed raw material, offering high forming efficiency. The resulting pellets are highly dense and have a stable structure. Therefore, they reduce storage and transportation costs, making them a popular choice among many alfalfa pellet manufacturers.

Moreover, the efficient conditioning process blends raw materials of different textures to ensure a rich nutritional content. This makes them the ideal feed processing equipment for many livestock farms.

We offer free consultations on production solutions and equipment around the clock.

We provide a one-stop service for alfalfa pellet production projects.

Alfalfa Pellet making Plant

Livestock Farms

Rapid Customisation Services

High Return on Investment

Global Projects

Through years of service accumulation, our alfalfa pelletizer machine has earned the trust and support from customers around the world. Below are some representative case studies. We deliver comprehensive solutions, whether supplying individual units or complete production line projects.

Alfalfa Pellet mill for Sale In Uzbekistan

The client’s raw materials consist of pasture grass, alfalfa and 40% grain. They intend to produce mixed-ratio grass feed pellets. We supplied a 1-2 T/H capacity pellet machine, which delivered excellent production results.

Alfalfa Pellet Machine for Sale In Argentina

Argentina has abundant alfalfa grass resources. The client requires finely granulated pellets with a target diameter of 6 mm. We supplied a alfalfa pellet mill with a capacity of three T/H.

Alfalfa grass Pellet Plant In USA

Our client has an ample supply of raw materials, primarily alfalfa mixed with some straw. We supplied multiple alfalfa pellet mills and a complete production line with a capacity of 11–12 T/H.

South African Alfalfa Pellet Production Project

In this project, raw materials include alfalfa hay and certain grains. The client required hay pellets for ruminant animal feed. Our equipment fulfills their ideal feed specifications and delivered excellent feeding results.

Alfalfa Pellet mill for Sale In Canada

This project is for a dairy farm client who requires a machine to produce compound feed, made from a mixture of alfalfa and pasture grass. Our equipment meets their requirements perfectly.

Spanish Alfalfa Pellet Manufacturing Plant

This project employs a high-capacity pelletiser with an impressive output of 4-5 T/H. It enables the client to process large quantities of alfalfa and mixed grains into premium-quality pellets, meeting the highest market standards.

Alfalfa feed Pellet Machine For Sale In Italy

The raw materials used for pellet production include pasture grass, alfalfa hay and corn. The farmer selected our equipment to produce high-quality mixed pellets and achieve additional economic benefits.

Alfalfa Pellet Production Project In Kazakhstan

The client required a versatile pellet mill for integration into an existing grass pellet production line. We supplied a 2-3 T/H alfalfa pellet mill, capable of producing mixed pellets from alfalfa, hemp and wheat.

Why Choose RICHI?

We offer industry-leading alfalfa pellet machine for sale.

RICHI Machinery was established in 1995, and we have remained dedicated to providing customers with the best pellet solutions. We are driven by customer satisfaction and are engaged in the research of pellet machinery. To date, we have successfully supplied high-quality alfalfa pelletizer machines to clients worldwide.

Drawing upon extensive customer service experience, we have a thorough understanding of your production needs and the challenges at every manufacturing stage. Consequently, we offer an integrated solution combining pre-sales and after-sales support to protect your alfalfa pellet production operations.

Our after-sales service includes a one-year warranty and a prompt response to any quality issues. To ensure rapid dispatch of components, we also maintain a global network of spare parts. If you encounter any production challenges, we will provide solutions to help you resume operations swiftly. We also offer the following services:

Free consultation Service

At RICHI, our experienced engineers and sales team offer free consultations on alfalfa pellet making machines. We understand your production requirements and queries, so feel free to ask us any questions you have about the production solutions.

Customised Equipment Service

Should you have specific requirement for output and standard for pellets, we can provide tailored solutions to meet your needs. Our specialist technical team and large-scale manufacturing facilities can accommodate all your equipment needs.

Turnkey Production Solutions

Besides exceptional pellet machines, our production line solutions have earned the trust and support of clients. Our turnkey solutions, in particular, offer complete service including project planning, construction, equipment installation and operator training.

Other Related Production Equipment

RICHI operates large-scale manufacturing facilities for production machinery. As well as advanced alfalfa pellet machine for sale, we design and manufacture other high-efficiency production machinery. These devices also play critical roles in alfalfa pellet production line.

Raw Material Crusher

It can grind grass and straw into a powder with a particle size of 5–20 mm, which facilitates pelletization.

Drum Dryer

It features a large capacity and a dual-barrel design for efficient, uniform drying of materials.

Cooling Machine

It rapidly cools high-temperature alfalfa pellets to room temperature through counter-current cooling.

Packaging Scale

It provides fully automated weighing and uniform packaging. Packaging options include heat-sealed bags and conventional sacks.

Frequently Asked Questions

Thanks to our global customer service, we are familiar with the various issues that you may face during the rice husk pellet production process. These include enquiries about rice husk pellet machine models, equipment maintenance, raw material selection and after-sales support, among others. Our compiled responses are provided below for your reference.

–

What are the demands on raw materials of our alfalfa pellet machine for sale?

Our highly versatile equipment is capable of pelleting a wide range of materials. The primary requirements for raw materials are therefore moisture content and cleanliness, which are fundamental criteria for grass feed production.

The ideal moisture level is 15–18%. Excessively high or low moisture content will adversely affect the pellet formation. If your raw material has an elevated moisture level, we can supply high-efficiency drying equipment. For materials with insufficient moisture, blending with other ingredients or adding a small quantity of water can achieve optimal pelleting conditions.

Furthermore, ensuring the cleanliness of raw materials is essential for producing high-quality alfalfa pellets. It is essential to inspect for contaminants such as metal or plastic, which could compromise pellet quality and cause equipment wear. We provide precision raw material screening equipment where required.

–

How do you choose the right alfalfa pellet making machine?

We offer custom-built alfalfa pellet machine for sale, with production capacities ranging from 0.5 to 8 T/H. Suitable for a variety of alfalfa pellet manufacturers and livestock farms, we recommend selecting a model based on the following considerations:

First, determine your target output and supply volume of raw materials. We advise allowing for a capacity margin of approximately 20% based on your current requirements, to allow for future expansion.

Then consider your actual investment budget. Not only do we offer advanced alfalfa pellet machines, cost-effective solution designs are also available. (View YouTube)

–

How to produce high-quality pellets with our alfalfa pellet making machine?

Firstly, ensure that the raw materials are clean and dry. It is crucial to ensure the absence of impurities for optimal pellet quality. An ideal moisture content of the raw material is 15-18%, which delivers optimal forming results.

Secondly, correct operation of the equipment. This includes conditioning temperature, proper die matching and maintenance. We offer user-friendly pellet machine for sale.

Next is prompt cooling and drying. Our counterflow coolers rapidly reduce the temperature and moisture content of the pellets, thereby preserving their optimal structure.

Finally, standardized packaging, sealing and storage procedures are essential. We provide complete pellet production line solutions to help you produce perfect pellets every time.

Furthermore, other high-fiber pelletizers are also suitable for the aforementioned production method. For example, hay pellet machine, hemp pellet machine, miscanthus pellet machine, corn stalk pellet machine, wheat straw pellet machine, rice straw pellet machine, and others.

–

What is the return on investment of the alfalfa pellet machine for sale?

We offer cost-effective alfalfa pellet machine for sale. The return on investment depends on your application. Different applications yield different returns. If you use our alfalfa pellet machine to produce feed for internal use, you will benefit from reduced raw material costs, minimized waste and improved feeding efficiency.

If you use it to produce pellets for sale, your returns will come from sales profits. These encompass product pricing, production costs, output capacity and operational losses. With stable sales, the initial investment can typically be recouped within one to three years.

–

What after-sales services are provided for the alfalfa pellet mill?

When you purchase one of our alfalfa pellet mill, the most comprehensive after-sales support is included. Each machine comes with a 12-month warranty to ensure any quality issues are resolved promptly. User manuals and video tutorials are included with equipment shipments to help you get up and running quickly.

Furthermore, our global spare parts network ensures the rapid supply of wear-prone components, such as ring dies and press rollers. If you encounter any technical issues during production, we can provide ongoing online guidance.

In addition to this pelletizer, our other equipment also comes with these after-sales services. For example, sawdust pellet machine, rice husk pellet machine, wood chip pellet machine, EFB pellet machine, peanut shell pellet machine, and others.