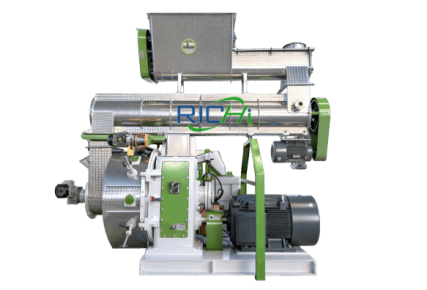

Wheat Straw Pellet Machine

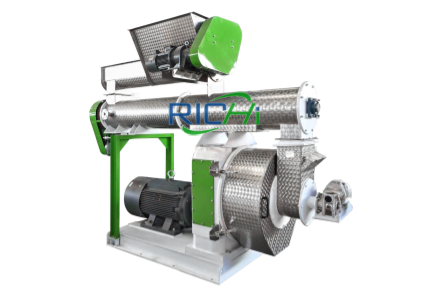

This wheat straw pellet machine is an industrial-grade device specifically engineered for straw pelletization. It can compress either 100% wheat straw or mixed materials into dense pellets. Its innovative pelletizing system ensures the production of superior-quality pellet fuel.

wheat straw Pellet Machine For sale

The long fibers and low binding properties of wheat straw result in poor pellet formation rates and quality. Therefore, we have specifically upgraded our pelletizer. It can produce high-quality wheat straw pellets efficiently.

This equipment operates at a high pelletizing temperature of 80°C. This enables the straw material to fully gelatinize, thereby achieving higher formation rates. It is equally suitable for pelleting mixed materials. For example, adding some wood chips can improve binding properties and pellet quality.

However, clogging remains a persistent challenge in wheat straw pellet production. Our pelletizer incorporates anti-accumulation and forced feeding mechanisms. Its dual-roll system and innovative ring die are also optimized for high-fiber materials. Consequently, it can produce pellets in a range of diameters from 4 to 12 mm.

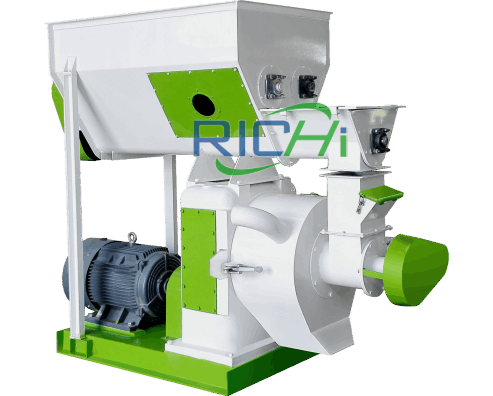

Parameters of wheat straw Pellet making Machine

| Model | MZLH 320 | MZLH 350 | MZLH 420 | MZLH 520 | MZLH 678 | MZLH 768 |

| Main Motor Power(kw) | 22 | 37 | 90 | 132 | 185 | 250 |

| Breaker Feeder Power(kw) | 2.2 | 2.2 | 3 | 3 | 3 | 4 |

| Forced Feeder Power(kw) | 0.75 | 0.75 | 1.5 | 1.5 | 1.5 | 1.5 |

| Ring Die Inner Diameter(mm) | 320 | 350 | 420 | 520 | 673 | 762 |

| Pellet Diameter(mm) | 4-12 | |||||

| Capacity(T/H) | 0.5-0.6 | 1.0-1.2 | 1.8-2.0 | 2.8-3.0 | 4-5 | 6-8 |

The above details the specifications and production capacity of this wheat straw pellet machine. You may select based on your requirements. Beyond these options, we also offer customized solutions. Should you require additional specifications, please feel free to contact us at any time.

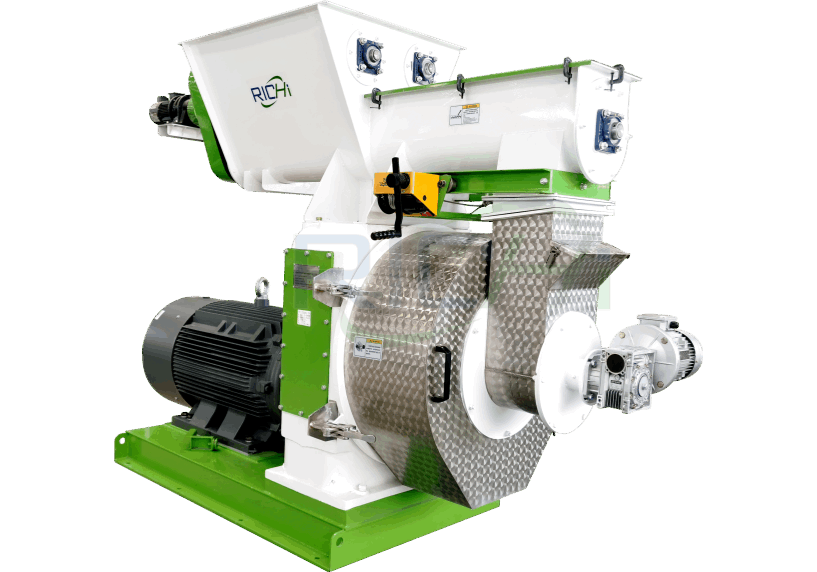

Scientific Structure Design

The industrial wheat straw pellet machine incorporates multiple scientific designs. We understand the challenges and requirements you face in producing wheat straw pellets. These design will address the issues, delivering a more efficient experience.

We have designed two anti-blocking devices for high-fiber straw materials at its two feed inlets: the bridge breaker feeder and the forced feeder. These structures ensure smoother and faster feeding, helping you to boost production efficiency.

Additionally, this equipment utilizes industrial-grade Siemens motors as the power system. Both feed inlets and the pelletizing chamber are equipped with dedicated motors.This design enables continuous and stable production.

01

Arch-breaking feeder

The enlarged feed inlet features two sets of counter-rotating agitator blades. These blades effectively prevent arching during feeding.

02

Forced Feeder

Material tends to accumulate above the granulation chamber. This device forces the material into the interior of the chamber.

03

cutting device

Unlike feed pelletizers, this device operates as a set. By extending the cutting intervals, it enables the production of longer pellets.

04

Exhaust Vent

A fan and cyclone can be installed here. This enables high-temperature steam to be vented without any material leaking.

05

Ring Die Mold

It features a scientifically optimized combination of apertures, enhancing output per unit. The alloy material offers superior hardness.

06

Dual-Roll System

The dual-roller structure effectively compresses straw material, which improves the formation rate and enables pellets to be longer.

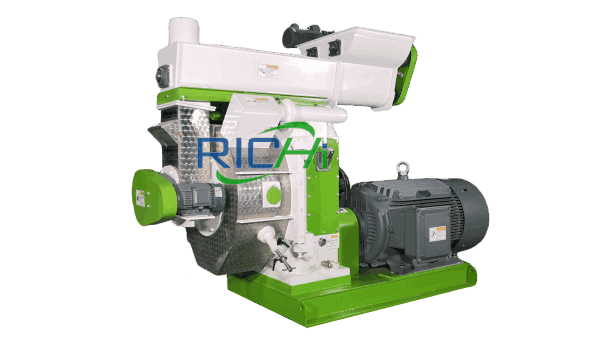

Advantages of wheat straw Pellet mill

This pelletizer boasts many technical advantages. Beyond its ease of operation and maintenance, it offers high efficiency and energy savings. Opting for this wheat straw pellet machine ensures an exceptional production experience.

Working Process Of wheat straw pelletizer

We have specifically optimized the pelleting process for this machine. The process takes place in a high-temperature steam environment to ensure optimal forming results and pellet quality.

- Feeding: Powdered wheat straw enter the pelletizer via an arch-breaking feeder.

- Conditioning: The material is thoroughly mixed in an environment of high-temperature steam at 80 °C.

- Extrusion: The dual pressure rollers exert intense pressure, forcing it into the apertures of ring die.

- Forming: The cylindrical material is discharged continuously from the apertures.

- Cutting: A dual-blade mechanism slices them into uniformly sized pellets.

The above outlines the fundamental pelletizing process for this wheat straw pellet machine. We will make parameter and component adjustments tailored to your specific production needs.

Since this process occurs in a high-temperature steam environment, the freshly produced wheat straw pellets are relatively moist and soft. Once cooled to room temperature, they harden. If you require complete wheat pellet production equipment, please feel free to contact us anytime.

Applications of wheat straw Pellet machine

Our pelletizer offers exceptional versatility. It can produce a wide range of straw pellets that meet various high-quality standards.

Processable straw Materials

Its robust material pelletizing system can handle various high-fiber crop straws. Even with mixed materials, it delivers consistent production results. Below are common raw materials used by our customers. If you have other pellet requirements, we can provide rapid custom solutions.

Wheat straw

Rice straw

Oat straw

Corn stalk

Cotton stalk

Corn cob

Available straw Pellets

Our wheat straw pellet machine can be used to produce biomass pellet products. It is ideal for biomass pellet plants, farms and wheat processing facilities. If you need to produce coarse feed, we can achieve this by adding a conditioner.

These high-quality pellets can be used in boilers, heating systems and power plants, among other applications. We provide different ring die hole sizes to suit various pellet needs.

Below are the pellet products manufactured using our machine. If you are looking for highly efficient, industrial pellet mill, you can confidently choose us.

wheat straw Pellets

Oat straw Pellets

Rice straw Pellets

corn stalk Pellets

Cotton stalks Pellets

corn cob Pellets

Mixed Straw Pellets

hay Pellets

Global CASES

Investors in biomass pellets from around the world have chosen our pellet mills. We also provide other machinery for wheat straw pellet plants. These cases include both individual equipment sales and turnkey solutions. We provide the perfect solution for every customer.

Wheat Straw Biomass Pellet Machine for Sale in Poland

Our client is a large-scale farm. They have large quantities of wheat straw and corn stalks that require pelletization. The client selected our 2-3 T/H pelletizer to produce 6 mm diameter straw pellets.

Agricultural straw pellet machine for sale in Kazakhstan

The customer operates a farm growing wheat and rice. With an abundant supply of straw materials, they require a pelletizer capable of processing mixed materials. Our equipment perfectly meets their requirements.

Wheat Straw Pellet machine for Sale in Argentina

The client is a feed mill. They require a pelletizer to process wheat straw and forage into roughage for ruminant animals. We supplied a pellet mill equipped with a conditioner. Its production capacity is 1.5-2 T/H.

wheat Straw fuel Pellet machine for sale in India

For this project, we provided a customized solution for producing straw pellets. The raw material is mixed straw. The production line has a capacity of 3–4 T/H and produces biomass pellets for power plants.

Wheat Straw Pellet Plant Project in Romania

The pellets produced by this project are primarily used in industrial boilers and heating systems. Therefore, the pellets have a diameter of 6 mm. We provided complete wheat straw pellet plant equipment with capacity of 1.8-2 T/H.

Wheat Straw Pellet Production Project in Turkey

This project is a wheat pellet plant solution. The primary raw material is wheat straw. The target fuel pellet size is 6 mm. Its configuration includes a 2–2.5 T/H pellet mill and other production equipment.

Why Choose RICHI?

We offer industry-leading wheat straw pellet machine for sale.

RICHI Machinery was founded in 1995, and we have consistently dedicated ourselves to providing customers with optimal pelletizing solutions. We prioritize customer satisfaction, delivering the best possible service.

With extensive customer service expertise, we deeply understand your production requirements. We offer comprehensive pre-sales and after-sales support to safeguard your wheat straw pellet production operations.

We offer a comprehensive pre-sales service. This includes free consultations on wheat straw pellet equipment. Our sales team is always available online to provide answers. We are also renowned for the attentive after-sales support, which includes the following specific services:

Long-Term Warranty

Every machine sold by RICHI comes with a one-year quality guarantee and fast shipping. For any quality issues arising during this period, you will receive prompt responses and proper resolutions.

Spare Parts Supply

We have established a global spare parts supply network. Built upon a global system of warehouses, this network ensures the rapid shipment and timely replacement of your worn parts.

Technical Support

Beyond dedicated equipment manuals and instructional videos, we offer installation and operational training for production line equipment, along with ongoing online technical guidance.

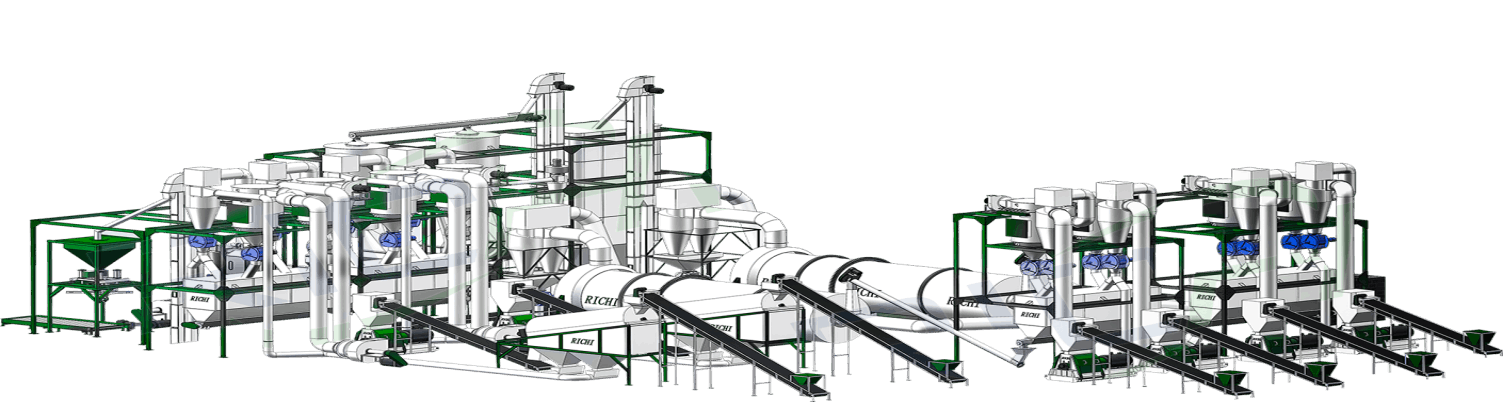

wheat straw Pellet Production Line

We not only provide advanced wheat straw pellet machines but also offer complete straw pellet production line equipment. This solution is ideal for industrial-scale production of straw pellets. The capacity ranges from 0.5 to 40 T/H. We also provide customized production lines and turnkey projects.

01

Crushing

Wheat straw should be crushed into powder prior to pelletization. We supply robust crushers at this stage. They can crush wheat straw into particles of 3-5 mm, meeting the ideal pelletization standard.

02

Drying

This processing section is designed for straw materials with high moisture content. We will configure the appropriate dryer for you, which will reduce the material moisture to the ideal range of 15%-18%.

03

Pelletizing

The wheat straw pelletizer is the main piece of equipment in this process. We will select the most suitable model for your target capacity. Then arrange the suitable ring die aperture and equipment parameters.

04

Cooling

If you require a rapid pellet cooling system, this process section delivers. Through highly efficient and energy-saving coolers, wheat straw pellets are quickly brought to a stable structure.

05

Screening

For straw pellet manufacturers, this process section enables you to screen out uniformly sized pellet products. It offers three pellet specifications and facilitates secondary pelletization of the material.

06

Packaging

We offer weighing and packaging machines with varying levels of automation. For pellet plants, selecting fully automated packaging processes can effectively reduce labor costs and minimize pellet loss.

Application Scenarios

This industrial-grade production line is suitable for various biomass pellet plants, large farms and similar operations. Its scientifically designed production stages boost efficiency while reducing costs and waste.

Additionally, our turnkey solution encompasses multiple services, such as project planning, on-site construction and operational training. If you require rapid production ramp-up, this is the ideal choice.

We offer free consultations on production solutions around the clock.

We provide a one-stop service for wheat straw pellets production project.

biomass straw Pellet Plant

Large-scale farm

Rapid Customization Services

High Return on Investment

Other Related Production Equipment

In addition to wheat straw pellet machine, we also manufacture other equipment for this production line. These components play a vital role in wheat straw pellet production and other solutions. We are committed to providing you with the highest quality pellet production experience.

Raw Material Crusher

This machine is a dedicated crusher for straw and forage. It can crush raw materials to a size of 5–20 mm.

Drum Dryer

It features a dual-chamber design for more efficient drying. The drying duration can be adjusted according to the material conditions.

Counterflow Cooler

It rapidly cools high-temperature straw pellets to room temperature through counter-current cooling.

Packaging Scale

It provides fully automated weighing and uniform packaging. The sealing method options include thermoplastic sealing, seam sealing, or mixed sealing.

Other pellet machines

We have also designed other innovative pellet machines. Like the wheat straw pellet machine, they offer energy-saving, eco-friendly and highly efficient performance. We are committed to providing you with premium pellet production in the long term.

corn stalk Pellet Machine

This machine is designed for pelletizing high-fiber corn stalks, and can handle mixed material pellets.

wood chip pellet machine

This is an industrial pelletizer that produces high-quality wood pellets from various wood raw materials.

sawdust pellet machine

It can compress loose sawdust into compact wood pellets, which are longer and more durable.

alfalfa pellet machine

Our alfalfa pellet machine is ideal for meeting your high-standard feed requirements.

hemp pellet machine

We offer efficient hemp pellet machines that produce high-protein feed effectively.

Frequently Asked Questions

We fully understand your concerns when selecting a wheat straw pellet machine. Therefore, we have compiled the following answers specifically for you. We hope this helps you understand this equipment. Should you have any further concerns, please do not hesitate to ask us.

–

What are the raw material requirements for a wheat straw pellet mill?

The pelletizing requirements for wheat straw are moisture content and particle size. The optimal moisture level for pelletizing is around 15%. If your straw has higher moisture content, it will affect the pellet structure. If the moisture content is too low, it will be difficult to form pellets. Therefore, you can use a dryer or add water to adjust the humidity of the material.

Additionally, the particle size of the straw material must be considered. The ideal size is a fine powder within the 3–5 mm range. Larger straw particles result in low pelleting rates and increased wear to the equipment. We can provide you with high-efficiency dryers and crushers.

–

What are the uses of wheat straw pellets?

Wheat straw is primarily used for combustion. However, wheat straw pellets have a wider range of applications. As a high-quality biomass fuel, they can be used in heating systems, boilers, power plants and similar facilities. Due to their excellent moisture absorption properties, they also serve as livestock bedding.

Moreover, blending wheat straw with other forage or grains can produce roughage. This feed is primarily used in ruminant animal husbandry to promote digestion and nutrient absorption. Whatever your application for wheat straw pellets, our pellet machines can accommodate it.

–

How to prevent blockages in wheat straw pellet machine?

You can prevent equipment blockages by checking the moisture content, grinding consistency, and cleanliness of raw materials. Our machines feature multiple anti-clogging and anti-blockage designs. Therefore, under normal processing conditions, blockages are unlikely to occur. Additionally, regular maintenance and inspection of wear on the equipment can effectively prevent blockages.

–

What other biomass materials can the wheat straw pellet machine process?

As well as wheat straw, this equipment can process other crop straws. It also meets the pelletizing requirements for mixed materials. We will configure the appropriate ring die based on your raw material conditions. This die achieves the optimal compression ratio regardless of the straw material.

If you require pelletizers for other agricultural husks, we also offer rice husk pellet machine, peanut shell pellet machine, EFB pellet machine, and others. (View YouTube)

–

How many operators are required for a wheat straw pellet making machine?

Our pelletizer is designed for user-friendly operation. It does not demand high professional expertise from operators. Typically, one or two people can complete the pelletizing process. One person monitors the equipment and inspects the finished pellets, while the other handles feeding.

If you wish to reduce labor costs, you can opt for a highly automated production line. This solution enables automatic feeding and equipment monitoring. The finished straw pellets will then automatically enter subsequent processing stages. This significantly reduces labor costs and improves production efficiency.