Sawdust Pellet Mill For Sale

This sawdust pellet mill for sale boasts highly efficient pelletizing capability. It is an energy-efficient equipment that can produce a variety of high-quality wood pellets. Contact us to receive a personalized introduction.

Advanced Sawdust Pellet Mill For Sale

Drawing upon our extensive experience in equipment development, our sawdust pelletizer offers superior granulation capabilities. The resulting sawdust pellets are of an enhanced quality that meets the highest standards.

Our machinery compresses loose sawdust into smooth, compact fuel pellets. This reduces storage and transportation costs, while also significantly boosting thermal efficiency and extending combustion duration. These premium sawdust pellets achieve zero carbon emissions, complying with environmental standards.

Standard pellet diameters are 6, 8 and 10 mm. Our pellet mill for sawdust can produce pellets ranging from 4–12 mm in diameter. It can also accommodate longer lengths of pellet, up to 4 to 5 times the diameter, meeting a wider range of requirements for pellet size.

Working Process of Sawdust Pellet Mill

The pellet mill for sawdust is an optimally designed unit capable of achieving efficient pelletization. The basic pelletization process is outlined below. We also provide you with customized solutions.

We offer high-efficiency sawdust pellet mill for sale.

Before starting the pelletising process, you must ensure that the sawdust is clean and free from contaminants such as iron filings or plastic. This will prevent reduced pellet quality and wear to equipment components. Once clean, the sawdust can be fed into the pelletiser to begin the process.

The material passes smoothly into the granulator via the arch-breaking feeder. High-temperature steam treatment activates the adhesive properties of lignin, making the material more malleable. The dual-roll system then continuously compresses it to extrude cylindrical pellets through the apertures of the ring die. Finally, the blades cut the material uniformly to produce standardised sawdust pellets.

The compressed pellets are discharged through the outlet beneath the pelletising chamber. Freshly produced sawdust pellets are initially damp and soft, which makes them unsuitable for packaging and transportation. They only attain a stable pelletised state once they have cooled to ambient temperature.

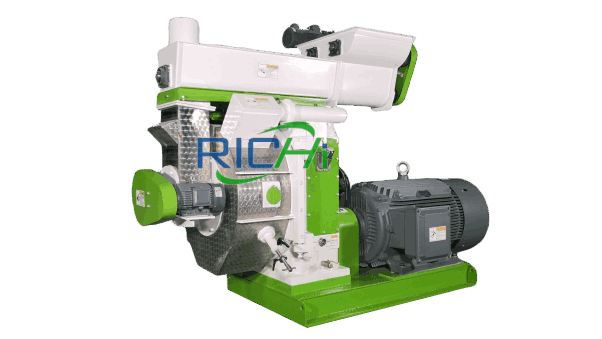

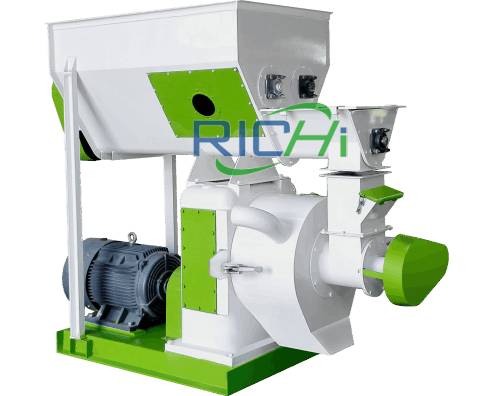

Scientific Design

With over thirty years of industry experience, we manufacture premium sawdust pellet mill for sale. Featuring scientifically engineered roller systems and die structures, our pelletisers deliver the finest production experience for sawdust pellets.

We have optimised the extrusion and polishing processes of the pelletiser to enhance pellet quality, enabling the production of smooth-surfaced, uniformly hard pellets. Our upgraded ring die moulds increase capacity and can produce pellets in a wider range of sizes.

To improve the stability of the pelletizer, we use a professional dynamic balancing tester to inspect the rotor. Through precise calibration, we achieve a stable pelletizing process. Our sawdust pellet press features numerous other scientific designs, all of which are aimed at delivering optimal results.

01

Feed Inlet

An arch-breaking feeder has been installed at this location, equipped with a dedicated motor. This ensuring smoother material feeding.

02

Pelletizing chamber Inlet

A forced feeding device has been installed here to propel accumulated sawdust into the pelletising chamber, accelerating the pelletising process.

03

Double-Roll System

Unlike feed pelletisers, this roller system has a wider working area, which makes it better suited to the loose structure of sawdust.

04

Ring Die Mold

The ring die achieves the optimum compression ratio consistently. Its rationalised aperture arrangement enables increased output per unit.

05

Ventilation Outlet

This design allows the rapid release of high-temperature water vapour from the granulation chamber, preventing overheating of the machine.

06

Power System

Every sawdust pellet machine comes fitted with a high-efficiency Siemens motor. This ensures stable operation during the pelletizing process.

Parameters of Sawdust Pellet Mill For Sale

| Model | MZLH320 | MZLH350 | MZLH420 | MZLH520 | MZLH678 | MZLH768 |

| Main Motor Power(kw) | 22 | 37 | 90 | 132 | 185 | 250 |

| Breaker Feeder Power(kw) | 2.2 | 2.2 | 3 | 3 | 3 | 4 |

| Forced Feeder Power(kw) | 0.75 | 0.75 | 1.5 | 1.5 | 1.5 | 1.5 |

| Ring Die Inner Diameter(mm) | 320 | 350 | 420 | 520 | 673 | 762 |

| Pellet Diameter(mm) | 4-12 | |||||

| Capacity(T/H) | 0.5-0.6 | 1.0-1.2 | 1.8-2.0 | 2.8-3.0 | 4-5 | 6-8 |

These details outline the specific production capacities of the pelletisers in this series. Each model has been meticulously engineered to deliver outstanding pelletising performance. If you require further information, please feel free to contact us regarding a customised solution.

Advantages of Sawdust Pellet Mill For Sale

Our sawdust pellet machine boasts a range of technical advantages. It delivers efficient and stable pelletizing performance, and also offers benefits such as reduced energy consumption and material savings. We offer the ideal sawdust pelletizer for you.

Applications of Sawdust Pellet Mill For Sale

Our sawdust pellet machine has a wide range of applications. It produces robust, high-quality pellets, making it an indispensable tool for biomass pellet manufacturing.

Processable Raw Materials

This pelletiser can process not only sawdust, but also other wood-based materials. Examples include broken logs and waste timber. We offer highly versatile sawdust pellet machine for sale.

Sawdust

Wood Shavings

Wood Chips

Wood Blocks

Branches

Bark

The Perfect Pellets

Our sawdust pellet machines can process a variety of raw materials into hard, compact pellets. These high-quality pellets have a smooth surface and stable structure that resists damage, thereby reducing transportation and storage costs.

Moreover, these pellets are longer than most commercially available products, delivering superior quality. We offer innovative sawdust pellet mill for sale. With an optimized pelletizing system, it can handle mixed raw materials and large-diameter wood after crushing, consistently producing high-quality pellets.

The pellets below were produced using our wood pellet machine. They all have an excellent structure. With our sawdust pelletizer, you can produce such flawless pellets too.

Sawdust Pellets

Wood Chip Pellets

Shavings Pellets

Branch Pellets

Bark Pellets

Sanding Dust Pellets

Board Pellets

Log Pellets

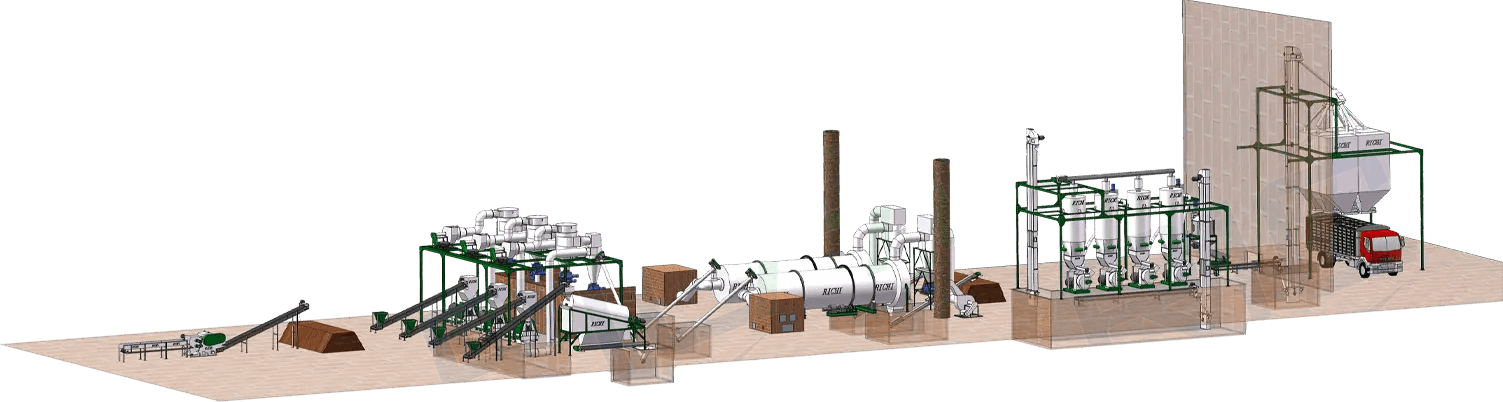

Sawdust Pellet Production Line

Our pellet mill for sawdust is the key piece of equipment in this production line. We provide customizable solutions for sawdust pellet production lines with capacities ranging from 0.6 to 100 T/H. These include high-efficiency raw material processing equipment and pelletizers, as well as pellet cooling, screening and packaging machinery. We also provide one-stop turnkey services for every wood pellet production line.

01

Cleaning

Sawdust typically contains large wood chips and other impurities that can affect the quality of pellets. This stage involves multiple cleaning devices that are designed to effectively remove metals, plastics and large wood chips from the sawdust.

02

Drying

The ideal moisture content for sawdust pelletisation is between 15% and 18%. If your raw material has a higher moisture content, our high-efficiency drying drum can resolve this issue. This stage rapidly dries the sawdust to ensure consistent pellet formation rates.

03

Pelletizing

Our sawdust pellet mill for sale is essential for this production stage. Based on your specific capacity needs, we can provide a suitable model of pellet mill or multiple units operating in parallel. This ensures that you achieve high-quality pelletisation results.

04

Cooling

Sawdust pellets treated with high-temperature steam become relatively moist and soft, so they need to be cooled and shaped quickly at this stage. We have designed multiple cooling units to meet different production capacities and operational scales.

05

Screening

This stage of the process has been designed to ensure uniform pellet size. It features multiple screening devices, including return-type grading screens and high-frequency screens. This stage can also separate smaller material for re-pelletisation.

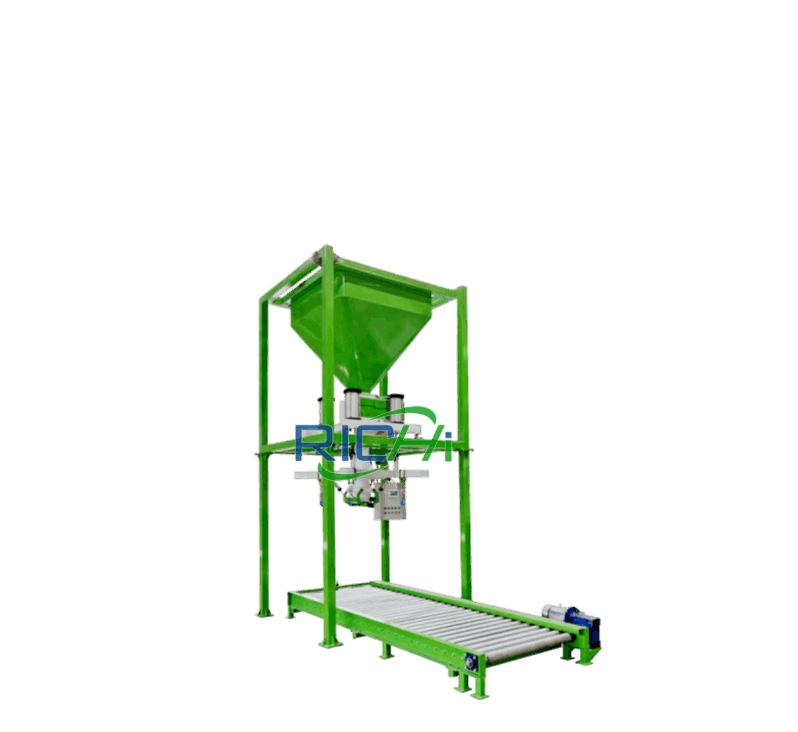

06

Packaging

This section offers a range of packaging equipment with varying automation levels. The fully automated packaging section enables automated weighing and packaging. This ensures uniform packaging specifications, reduces pellet loss and cuts labour costs.

Application Scenarios

We supply high-quality pellet mill for sawdust , which are suitable for processing various types of wood into pellets. This pelletizer can compress a variety of wood processing waste into uniform, full-bodied pellets. Consequently, it is ideal for wood processing plants of all sizes, providing additional economic benefits.

With high formation efficiency and energy-saving characteristics, this machine is the preferred choice for numerous sawdust pellet processing plants. The high-quality pellets produced meet stringent sales requirements.

We offer free consultations on production solutions and equipment around the clock.

We provide a one-stop service for sawdust pellet production projects.

Biomass Sawdust Pellet making Plant

Wood Processing Plant

Rapid Customisation Services

High Return on Investment

Global Projects

Thanks to the advanced manufacturing technology and premium service system, we have earned the trust and support of customers worldwide. Whether a single sawdust pellet mill for sale or a complete production line, we deliver results that meet your expectations.

Sawdust Pellet machine for Sale in Indonesia

The production feedstock consists of sawdust and wood chips. The target pellet diameter is 6 mm. We have supplied a precision pelletiser with a production capacity of 1.8–2 T/H.

Sawdust Pellet Mill for Sale in Romania

A Romanian client selected our 2-2.5 T/H pellet mill to produce sawdust pellets measuring 6-8 mm in diameter for sale. We also supplied additional production equipment.

Sawdust Pellet press for Sale in Singapore

This client had large quantities of sawdust and a small amount of wood shavings. The 2 T/H pelleting machine we supplied enabled them to produce high-quality pellets, yielding excellent returns.

Australian Sawdust Pellet Production Project

This project is a customised solution. We supplied the client with a 2 T/H sawdust pellet machine and other high-efficiency production line equipment to perfectly meet their manufacturing needs.

Sawdust Pellet Mill for Sale in South Africa

This furniture factory has a large quantities of small-diameter wood blocks, wood shavings and sawdust, which require efficient recycling via a pellet mill. Our 2 T/H pelletizer meets this need.

Sawdust Pellet press for Sale in Canada

The client possesses large volumes of waste boards and some sawdust. We supplied a pelletiser capable of producing 6 mm diameter pellets, high-efficiency wood chipper and pellet cooler.

Sawdust Pellet Production Plant in USA

This project required a flexible sawdust pellet production line with a target capacity of 10 T/H. Our sawdust pellet machine fulfills the demand for efficient mixing and pelletization.

Bangladesh Sawdust Pellet Production Line Project

The client operates a large-scale biomass pellet making plant, primarily processing sawdust, wood shavings and wood chips. We delivered a turnkey solution, achieving an output of 20 T/H.

Why Choose RICHI?

We offer sawdust pellet mill for sale, along with the most comprehensive service.

RICHI Machinery was established in 1995, and we have remained dedicated to providing customers with the best pellet solutions. We are driven by customer satisfaction and are engaged in the research of pellet machinery. To date, we have successfully supplied high-quality sawdust pellet machines to clients worldwide.

Drawing upon extensive customer service experience, we have a thorough understanding of your needs and the challenges at every production stage. Consequently, we offer an integrated solution combining pre-sales and after-sales support to protect your sawdust pellet production operations.

Our after-sales service includes a one-year warranty and a prompt response to any quality issues. To ensure rapid dispatch of components, we also maintain a global network of spare parts. If you encounter any production challenges, we will provide solutions to help you resume operations swiftly. We also offer the following services:

Free consultation Service

At RICHI, our experienced engineers and sales team offer free consultations on the sawdust pellet machine for sale. We understand our clients’ production requirements and queries, so feel free to ask us any questions you have about the production solutions.

Customised Equipment Service

Should you have specific requirement for output and standard for pellets, we can provide tailored solutions to meet your needs. Our specialist technical team and large-scale manufacturing facilities can accommodate all your equipment needs.

Turnkey Production Solutions

Besides exceptional sawdust pelletizer, our production line solutions have earned the trust and support of clients. The turnkey solutions, in particular, offer complete service including project planning, construction, equipment installation and operator training.

Other Related Production Equipment

In addition to the sawdust pellet mill for sale, we also supply equipment for other production stages. Below are some of the main units that are commonly used. RICHI boasts an experienced manufacturing team and large-scale equipment production facilities. Therefore, we can provide the ideal solution for your sawdust pellet production needs.

Cleaning Screen

It rapidly separates impurities from powdered materials through high-frequency vibration.

Drum Dryer

It features a large capacity and a dual-barrel design for efficient, uniform drying of materials.

Cooling Machine

It rapidly cools high-temperature sawdust pellets to room temperature through counter-current cooling.

Packaging Scale

It provides fully automated weighing and uniform packaging. Packaging options include heat-sealed bags and conventional sacks.

Frequently Asked Questions

With years of global customer service experience, we have a thorough understanding of the issues and queries that may arise in sawdust pellet production. We have compiled some frequently asked questions regarding sawdust pelletizer for sale. We hope you find this information useful. If you have any further questions, please feel free to contact us.

–

What are the raw material requirements of the sawdust pellet mill for sale?

The most important thing is that the raw material meets the basic conditions required for pelletization. Firstly, the moisture content of sawdust must be suitable. The ideal moisture level is 15%. Sawdust can easily absorb moisture. Excessive moisture makes it difficult to form pellets, while insufficient moisture reduces binding strength. We offer high-efficiency drying drums to address this issue.

Secondly, impurities must be removed. Contaminants such as iron filings or sand in the sawdust not only compromise pellet quality, but also accelerate die wear. Therefore, impurities must be screened out prior to pelletization to ensure material purity.

–

Which factors should be considered when choosing the sawdust pellet press?

The key considerations during the selection process are motor power, ring die material, aperture range and supplier reputation. Motor power refers to the operating capacity of the main motor and determines whether the output meets required specifications. The material of the ring die affects its wear resistance and service life. Our ring dies utilise 42CrMo alloy material for enhanced durability.

The range of aperture sizes affects the diameter of the sawdust pellets, with our machines offering diameters between 4 and 12 mm. Finally, selecting an experienced supplier ensures the long-term stable operation of the sawdust pellet mill.

–

How should you select a pellet mill for sawdust or a production line solution?

We recommend considering both the condition of your raw material and your investment budget. If your raw material is already crushed to 3–5 mm and is free of impurities, purchasing a single machine will suffice. If you have a sufficiently large budget, our fully automated production line solutions can offer considerable convenience.

–

How should this sawdust pellet mill for sale be maintained?

The daily maintenance of the pelletizer must be carried out strictly in accordance with the equipment manual. This includes regularly inspecting for signs of wear and tear, promptly clearing residual material to prevent corrosion, and establishing a systematic maintenance schedule. Such regular, standardized maintenance significantly reduces downtime and extends the service life of components.

–

How often do components need replacing on this sawdust pellet mill for sale?

Ring dies and press rollers are the main wear parts on pellet machines. Our wear parts are made from wear-resistant alloy materials, offering greater durability and allowing for longer replacement intervals. Under normal production conditions, our ring dies can last for hundreds or even thousands of hours.

However, when processing hardwoods, the ring die and press rollers will wear out more quickly. We recommend regularly inspecting wear levels and promptly replacing components to avoid compromising pellet output.