rice Straw Pellet Machine

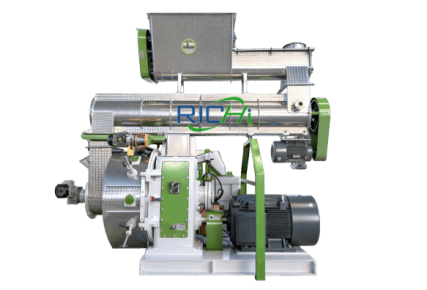

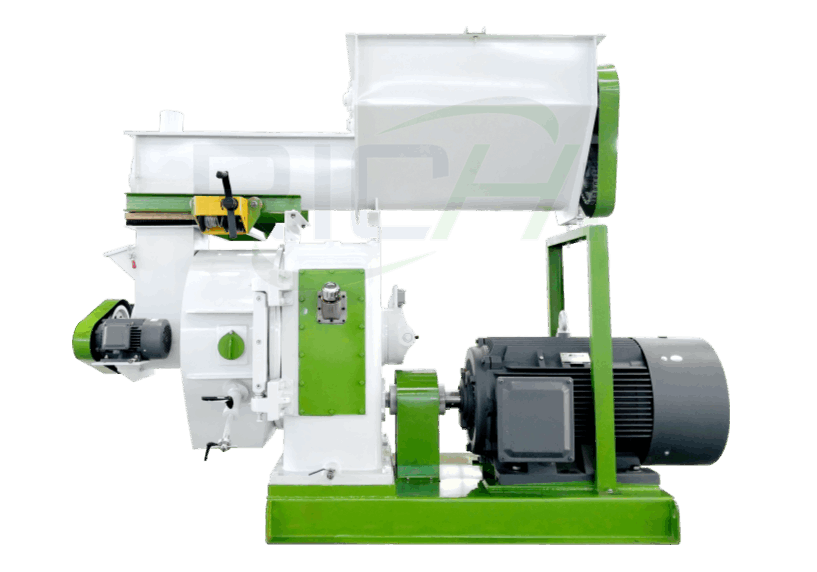

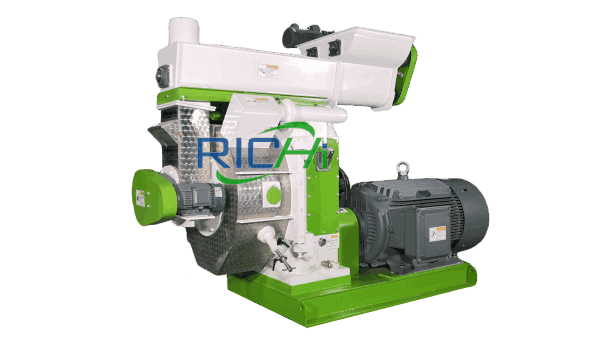

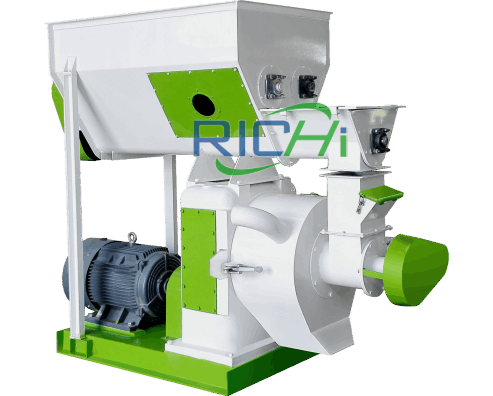

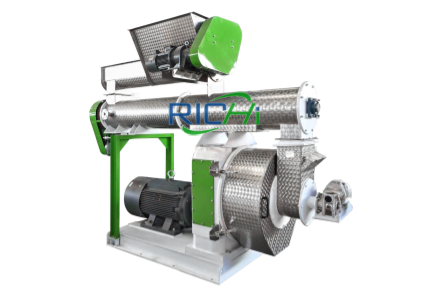

This rice straw pellet machine is an industrial-grade equipment for producing biomass pellets. It adapts to the high-fiber characteristics of rice straw, consistently producing high-quality fuel pellets. We also offer customized solutions for large-scale biomass pellet production.

rice straw Pellet Machine For sale

Rice straw has long fibers and high resilience, which can significantly wear down equipment. As a result, traditional straw pelletizers face challenges in forming pellets and are prone to clogging and slippage. However, our rice straw pellet mill effortlessly resolves these issues.

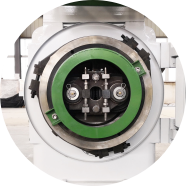

We have optimized the rollers and ring die of the pellet mill to address difficult forming issues. The dual-roller structure enables superior compression of materials, thereby enhancing forming efficiency. The innovative ring die adapts to high-fiber straw, consistently achieving optimal compression ratios.

Our pelletizer has dual feed inlets, each of which is equipped with anti-clogging devices. These prevent material build-up and ensure smooth feeding. When combined with the robust pelletizing system, it consistently produces straw pellets with diameters ranging from 4 to 12 mm.

Parameters of rice straw Pellet mill

| Model | MZLH 320 | MZLH 350 | MZLH 420 | MZLH 520 | MZLH 678 | MZLH 768 |

| Main Motor Power(kw) | 22 | 37 | 90 | 132 | 185 | 250 |

| Breaker Feeder Power(kw) | 2.2 | 2.2 | 3 | 3 | 3 | 4 |

| Forced Feeder Power(kw) | 0.75 | 0.75 | 1.5 | 1.5 | 1.5 | 1.5 |

| Ring Die Inner Diameter(mm) | 320 | 350 | 420 | 520 | 673 | 762 |

| Pellet Diameter(mm) | 4-12 | |||||

| Capacity(T/H) | 0.5-0.6 | 1.0-1.2 | 1.8-2.0 | 2.8-3.0 | 4-5 | 6-8 |

The above list displays the production capacity and power ratings of different pelletizer models. In addition, we offer customized rice straw pellet machine for you. Feel free to contact us anytime to discuss your production requirements.

Scientific Structure Design

This rice straw pelletizer machine features several innovative designs, such as anti-clogging structures, high-efficiency press rollers and ring dies. These designs enable the machine to deliver high efficiency and energy savings.

The ring die and press roll are the wear-prone components of the rice straw pellet machine. Both parts are made of alloy material and undergo carburizing heat treatment to provide excellent wear resistance.

To enhance stability and ensure efficient, long-lasting output, we have installed multiple sets of specialized motors at critical points. These industrial-grade 8-stage Siemens motors guarantee stable, consistent straw pellet production.

01

Arch-breaking feeder

This device consists of two sets of spiral feed plates, which can ensure the smooth entry of straw material through counter-rotation.

02

Forced Feeder

A forced feeder is installed at this point to facilitate smooth feeding through the inlet and accelerate the pelletizing process.

03

cutting device

Unlike feed pelletizers, this device operates as a set. By extending the cutting intervals, it enables the production of longer pellets.

04

Exhaust Vent

This device can be used alongside a fan and cyclone to help discharge high-temperature water vapor from inside the unit.

05

Observation Port

Through this viewing port, you can monitor the granulation process in real time, helping to prevent equipment clogging.

06

Pelletizing Chamber

This section features a dual-pressure-roller structure and alloy ring die, capable of generating powerful compression effects.

Advantages of rice straw Pellet machine

Through innovative structural upgrades, this rice straw biomass pellet machine boasts multiple technological advantages. It not only enables efficient, energy-saving production but also reduces labor and material costs, helping you achieve a quick return on investment.

Working Process Of rice straw pellet machine

The granulation process is conducted under high-temperature steam at 80°C, which enables the materials to bind thoroughly. Every step is scientifically designed to ensure efficient pelletizing.

- Feeding: Powdered rice straw enter the pelletizer via an arch-breaking feeder.

- Conditioning: The material is thoroughly mixed in an environment of high-temperature steam at 80 °C.

- Extrusion: The dual pressure rollers exert intense pressure, forcing it into the apertures of ring die.

- Forming: The cylindrical material is discharged continuously from the apertures.

- Cutting: The blade inside the granulation chamber cuts them into pellets of the desired length.

If you need to produce straw feed for ruminants, it can be achieved by adding a conditioner. This will better gelatinize the material, which facilitates digestion and absorption.

Once these straw pellets have cooled to room temperature, they will stabilize into the optimal pellet structure. Subsequent screening and packaging processes can now proceed. For expedited production needs, we also offer high-efficiency cooling, screening and packaging equipment for pellets.

Applications of rice straw Pellet mill

Our pellet mills can meet your diverse industrial pellet production needs. Whether you require clean fuel, animal feed or bedding, they can handle it with ease.

Processable straw Materials

This rice straw pellet machine features multiple specialized upgrades for pelletizing lightweight materials. Therefore, it is equally suitable for granulating other high-fiber straws and hay. It also delivers consistent performance when producing pellets from the following raw materials.

Rice straw

Wheat straw

Oat straw

Corn stalk

Cotton stalk

Corn cob

Available straw Pellets

With its stable pelletizing efficiency and clog-resistant design, this pelletizer is ideal for industrial-scale straw pellet production. The finished pellets can be used in industrial boilers, district heating systems and power plants.

Standard pellet diameters are 6 mm, 8 mm and 10 mm. However, our equipment can produce straw pellets ranging from 4 mm to 12 mm in diameter, with lengths reaching 4–5 times the diameter.

Below are the pellet products produced using our rice straw pellet machine. If you require such high-efficiency industrial equipment, please feel free to contact us anytime.

rice straw Pellets

wheat straw Pellets

oat straw Pellets

corn stalk Pellets

Cotton stalks Pellets

corn cob Pellets

Mixed Straw Pellets

hay Pellets

Global CASES

As the biomass pellet industry grows, an increasing number of investors are choosing our pelletizing equipment. Below are some of the projects we have completed for rice straw pellets. These include individual pellet mill sales and complete straw pellet production line solutions.

Biomass straw pellet plant project in USA

Our client operates a large-scale straw pellet plant requiring complete rice straw pellet plant equipment. The raw materials are rice straw and corn stalks. We provided turnkey services to facilitate a rapid production start-up.

Rice Straw Pellet Making Machine for Sale in Bangladesh

This project is designed for small-scale production at 1-1.5 T/H. The pellets are primarily used for ruminant feed, hence the specified diameter of 6 mm. We have provided a straw pelletizer equipped with a conditioner.

Biomass Rice Straw Pellet Project in India

The client requires large-scale production of fuel pellets from rice straw. The pelletizer’s high wear resistance makes it exceptionally suitable for processing 100% straw. It meets the client’s demand for continuous production.

Rice Straw Pellet machine for Sale in Indonesia

The client requires the production of biomass pellet fuel for export. The primary raw materials are rice straw and wood chips. We have supplied a 1.5-2 T/H pellet mill capable of producing 8 mm diameter straw pellets.

Mixed Straw Pellet Production Project in Thailand

The client is a large-scale farmer who utilizes rice straw, rice husks and wood chips as raw materials. This project required pellet mill to process mixed feedstocks. We provided ideal pelletizer and other processing equipment.

Small rice Straw Pellet Mill for Sale in Vietnam

This project requires a biomass straw pellet mill for fuel production. The pellets are used for small-scale boiler combustion and household heating. We provided a 1–1.2 T/H pelletizer to produce 6 mm diameter pellets.

Why Choose RICHI?

We offer industry-leading rice straw pellet machine for sale.

RICHI Machinery was founded in 1995, and we have consistently dedicated ourselves to providing customers with optimal straw pelletizing solutions. We prioritize customer satisfaction, delivering the best possible service.

With extensive customer service expertise, we deeply understand your production requirements. We offer comprehensive pre-sales and after-sales support to safeguard your rice straw pellet production operations.

We offer a comprehensive pre-sales service. This includes free consultations on rice straw pellet equipment. Our sales team is always available online to provide answers. We are also renowned for the attentive after-sales support, which includes the following specific services:

Long-Term Warranty

Every machine sold by RICHI comes with a one-year quality guarantee and fast shipping. For any quality issues arising during this period, you will receive prompt responses and proper resolutions.

Spare Parts Supply

We have established a global spare parts supply network. Built upon a global system of warehouses, this network ensures the rapid shipment and timely replacement of your worn parts.

Technical Support

Beyond dedicated equipment manuals and instructional videos, we offer installation and operational training for production line equipment, along with ongoing online technical guidance.

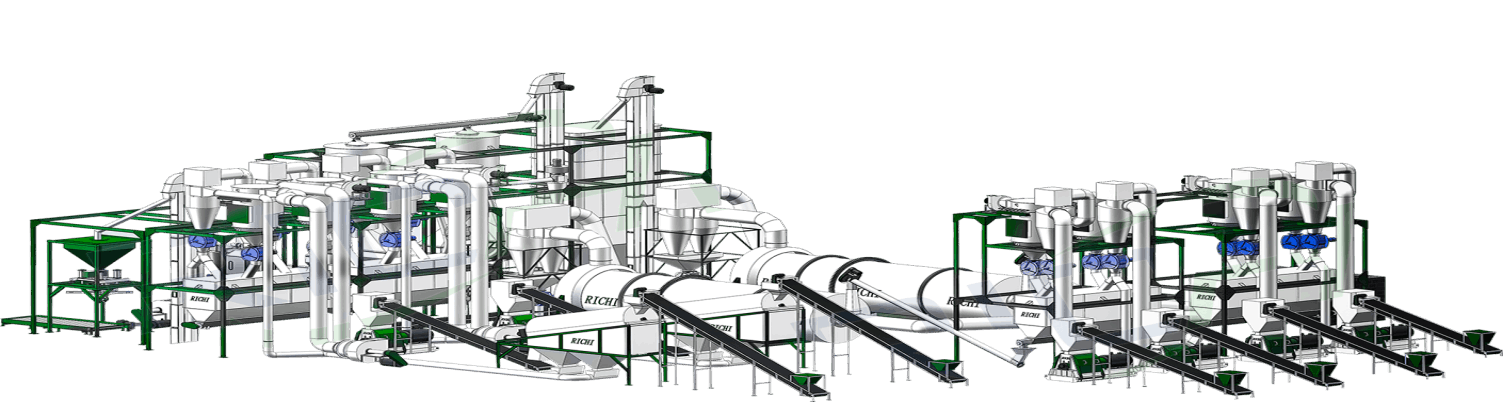

rice straw Pellet Production Line

Besides advanced rice straw pellet machine, we also offer comprehensive production line equipment. The rice straw pellet production line has scientifically divided work sections, supporting industrial-scale production with capacities ranging from 0.5 to 40 T/H. We also offer customized solutions and turnkey project services.

01

Crushing

To achieve optimal particle quality, rice straw must be pulverized into a powdery material measuring 3-5 mm. This process uses a dedicated straw and forage crusher, which can produce uniform grinding results quickly.

02

Drying

Rice straw stored outdoors is highly susceptible to moisture absorption, which requires drying process to reduce its humidity. Our large-capacity dryers can help it achieve the ideal moisture content of between 15%-18%.

03

Pelletizing

The rice straw pelletizer serves as the primary equipment for this process. Standard straw material can be turned into high-quality pellets at this stage. It has multiple ring die hole sizes to produce different pellets.

04

Cooling

Freshly pellets must be cooled and set before packing and transporting. Therefore, this process is ideal for enhancing the production efficiency. Our cooling system is energy-efficient and reduces pellet loss.

05

Screening

This unit provides pellets screening in three different sizes. We have designed a range of pellet screeners with different screening methods. The vibrating screen can be assembled with the cooler to save space.

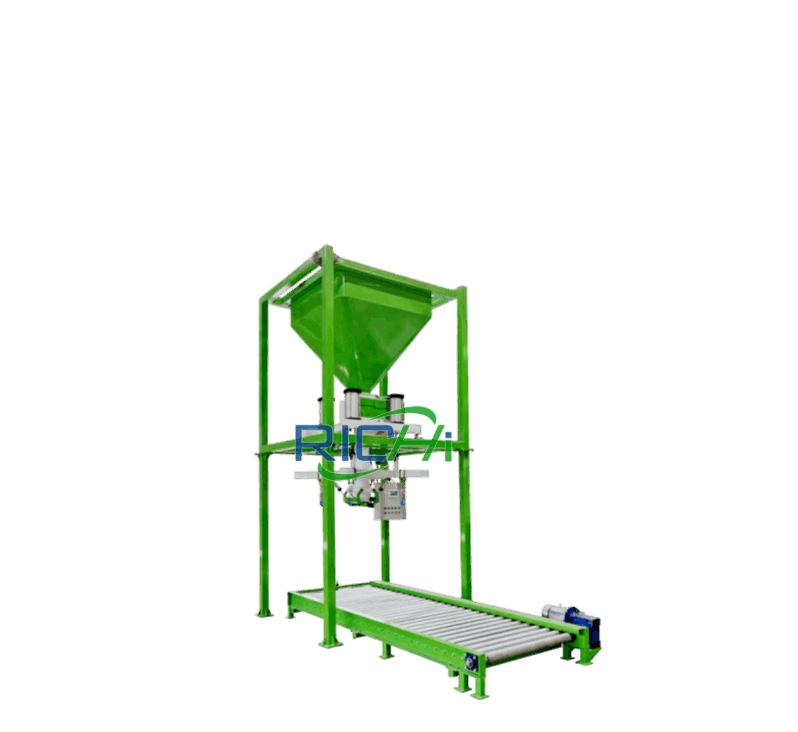

06

Packaging

We offer pellet packaging scales with different automation levels and packaging methods. If you need to reduce labor costs while maintaining uniform packaging standards, we recommend a automatic scale.

Application Scenarios

The production line process is flexible. We can provide customized production line based on your specific needs. If you require ruminant feed production, we can supply the necessary equipment.

We also offer turnkey solutions. These are suitable for rice straw pellet plants, biomass pellet plants, feed mills and large-scale farms, helping you to start production quickly and efficiently.

We offer free consultations on production solutions around the clock.

We provide a one-stop service for rice straw pellets production project.

biomass straw Pellet Plant

feed plant

Rapid Customization Services

High Return on Investment

Other Related Production Equipment

Just like the rice straw pellet machine, we also supply other equipment for this production line. These upgraded units can handle high-fiber, lightweight straw effectively. We can provide customized solutions to meet your diverse equipment needs.

Straw Crusher

It can rapidly and uniformly crush straw while removing metallic impurities. The final product has a diameter of 5–20 mm.

Drum Dryer

It has a double-layer drying cylinder and spirally arranged agitator blades. It allows flexible drying times based on the moisture content of material.

Counterflow Cooler

It lowers the pellet temperature by circulating cold air through them. These cooled pellets are no more than 3–5 °C above room temperature.

Packaging Scale

It provides fully automated weighing and uniform packaging. The sealing method options include thermoplastic sealing, seam sealing, or mixed sealing.

Other pellet machines

As professional biomass pellet machine manufacturer, we offer pelletizers capable of pelletizing various biomass materials. Like the rice straw pellet machine, these units deliver high formation rates, energy efficiency and wear resistance. We look forward to hearing from you with your requirements.

corn stalk Pellet Machine

This machine is designed for pelletizing high-fiber corn stalks, and can handle mixed material pellets.

wheat straw pellet machine

This is an industrial pelletizer that produces high-quality straw pellets from high-fiber wheat straw.

sawdust pellet machine

It can compress loose sawdust into compact wood pellets, which are longer and more durable.

alfalfa pellet machine

Our alfalfa pellet machine is ideal for meeting your high-standard feed requirements.

hemp pellet machine

We offer efficient hemp pellet machines that produce high-protein feed effectively.

Frequently Asked Questions

We fully understand your concerns when selecting a rice straw pellet machine. Therefore, we have compiled the following answers specifically for you. We hope this helps you understand this equipment. Should you have any further concerns, please do not hesitate to ask us.

–

Can this rice straw pelletizer directly pelletize straw?

No. Rice straw possesses high fiber content and high moisture levels. Direct pelletization will cause equipment clogging and wear, which affects pellet formation rates. Therefore, before pelletizing, it must be shredded and ensure an appropriate moisture content.

The ideal raw material is powdered with a diameter of 3–5 mm. The moisture content must be controlled to around 15%. Once properly processed, the straw can be easily pelletized into high-quality pellets.

–

What are rice straw pellets used for?

The most common use is as fuel pellets for power plants, boilers, district heating systems and residential heating systems. This reduces energy waste and pollutant emissions, providing economic and environmental benefits.

Beyond this, mixing rice straw with forage grasses and grains can produce coarse straw feed. This is primarily used in ruminant animal feed and increases dietary fiber intake, promoting digestion and absorption.

Its excellent absorbency also makes it suitable for use as animal bedding. Naturally, straw pellets for different applications require different pellet sizes. Our pellet mills can be configured with different ring die apertures and parameters to meet production needs for all these uses.

–

What are the common sizes for rice straw pellets?

The most common diameters available on the market are 6 mm, 8 mm and 10 mm. Our pelletizer can produce straw pellets ranging in diameter from 4 to 12 mm. The typical length of the pellets is 20–40 mm. However, this pelletizer can accommodate longer pellets, up to 4–5 times the diameter.

For applications such as small boiler combustion and residential heating, we recommend pellet diameters of 6–8 mm. For industrial-grade boilers and large-scale power plants, it is best to produce pellets with a diameter of 8–10 mm.

–

Can this rice straw pellet machine handle rice straw with high ash content?

Materials with high ash content generally cause wear to equipment. However, our ring die and rollers are made from 42CrMo alloy steel and undergo carburizing heat treatment. Their surfaces feature a 2 mm-thick hardened carbide layer to significantly enhance wear resistance.

Furthermore, the die’s optimized structural design consistently achieves optimal compression ratios. Accordingly, this equipment can effectively process high-ash materials, including rice straw with an ash content ranging from 6–10%. (View YouTube)

–

What other biomass materials can the rice straw pellet machine process?

The rice straw pelletizer is designed for crop straws. Therefore, it can produce pellets from most straws and crop husks. Examples include wheat straw, corn stalks, rice husks and corn cobs. It is also suitable for mixed pelletizing of various materials.

Our flexible equipment offers excellent utilization rates, helping you achieve a quick return on investment. We also provide other specialized pelletizers. These include wood chip pellet machine, rice husk pellet machine, peanut shell pellet machine, EFB pellet machine, and others.