rice Husk Pellet Plant

This solution can help rice husk pellet plants transform loose husks into compact pellets. Whether you require fuel pellets, animal feed or bedding material, this system can be adapted to your needs. We can also provide customized services and turnkey solutions to help you easily achieve ideal pellets. Contact us to get your bespoke solution.

High-Efficiency Rice Husk Pellet Plant solution

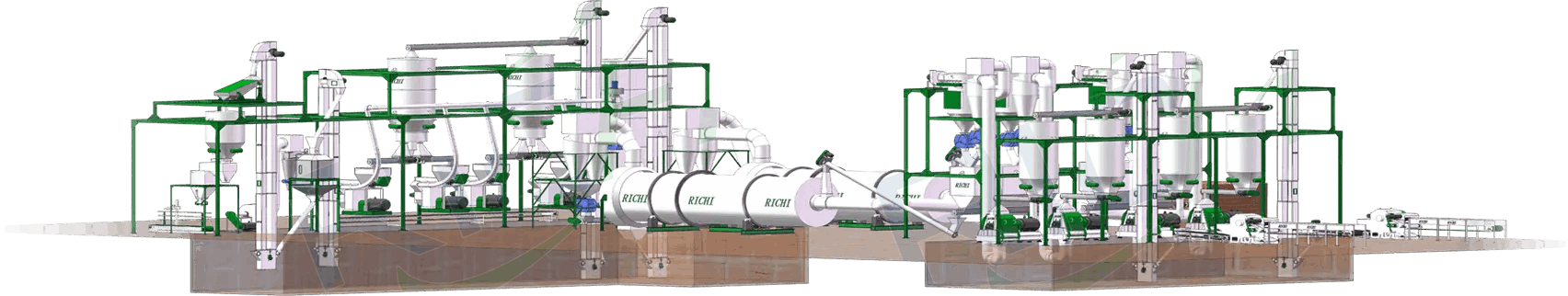

Our production solutions boast high-efficiency production equipment and auxiliary devices. These components work together perfectly to produce rice husk pellets with diameters ranging from 4 to 12 mm. They can also accommodate special requirements for pellet length, achieving lengths of up to 4–5 times the diameter.

We also offer pellet plant solutions with varying levels of automation based on your production needs. These lines are fitted with automated inspection and control systems. These systems enable real-time monitoring of production status, ensuring efficient rice husk pellet production.

We offer customized production capacities ranging from 0.6 to 40 T/H. In addition, we have implemented a scientifically structured division of production segments. As well as professional rice husk pellet machines, we have also designed other production equipment. Each segment is equipped with robust machinery and convenient auxiliary devices. We also offer customized production process design to meet your diverse manufacturing requirements.

Complete process flow

The following is the standard production process.

Cleaning

Drying

Pelletizing

Cooling

Screening

Packaging

application of rice husk pellet plant solution

We provide complete production solutions for various rice husk pellet plants. With them, you can produce high-calorific rice husk fuel or palatable feed pellets. Thanks to their high water absorption, the pellets are also suitable for animal bedding. Whatever your application, this solution delivers perfectly.

Production Section of rice Husk Pellet plant

Our solution for rice husk pellet plant features scientifically divided process segments. These include refined raw material processing, efficient granulation and rapid packaging. Each segment is equipped with a control system that allows you to adjust production plans flexibly based on specific conditions.

01

cleaning Stage

Rice husks are usually harvested and hulled mechanically. However, this process can introduce impurities, such as iron filings and sand. Therefore, preliminary cleaning is required to prevent wear to the ring die and press rollers, thereby ensuring the quality of pellets.

02

drying Stage

Rice husk material has excellent water absorption properties, which can lead to excessive moisture content and affect the formation of pellets. This process uses a large-capacity drying drum to uniformly dry the rice husks to an ideal moisture level for granulation.

03

pelletizing Stage

This section is a critical part of the rice husk pellet production. Based on your raw material ratio and production capacity needs, we will provide the appropriate husk pellet machine. The number of conditioners will also be adjusted according to the required conditioning level.

04

cooling Stage

Freshly produced rice husk pellets are soft and moist, which makes them unsuitable for packaging and transportation. However, rapid cooling at this stage can stabilize the pellet structure, making them ideal for transport and extending the storage life.

05

screening Stage

If you require uniform pellet specifications, this stage ensures compliance. Our screening equipment can separate different sizes of pellets and materials simultaneously, which facilitates packaging and secondary granulation. It also reduces material costs.

06

packing Stage

We offer packaging equipment with varying levels of automation for this stage. Highly automated pellet packaging scales can quickly weigh and package, which saves labor costs. Packaging options include heat sealing, thread stitching and hybrid sealing.

The above outlines the standard process segments for this rice husk pellet processing solution. Each segment is flexible and can be customized to meet your specific production requirements. We can also configure an optimal equipment solution tailored to your needs. Please contact us to obtain your customized production plan.

Raw Materials for rice Husk Pellet Production

The rice husk pellet plant solution we design are highly versatile. As well as rice husks, they can efficiently pelletize other agricultural crop husks and fruit shells. We provide customized equipment and production line solutions to meet all your husk pellet needs.

rice husks

Peanuts Shells

sunflower seed shells

Cotton seed hulls

Walnut shell

Empty Fruit Bunches

coffee husks

Almond Shells

Corn Cobs

Wheat Bran

The above lists the raw materials that are compatible with the rice husk pellet production. Our customized solutions ensure perfect quality for every kind of husk pellet. We also offer production equipment for other types of raw material. Please feel free to contact us anytime if you are seeking these solutions.

Pellets from Rice Husk Pellet production system

This industrial rice husk pellet plant solution is suitable for producing various types of husk pellets. Despite the different ratios of raw materials, they all have the same excellent structure and perfect specifications. Choose our solution and you can produce perfect pellets, too.

Rice husk pellets

Rice husk typically has lower pellet formation rates than wood chips, due to its lack of natural binding agents such as lignin. Our advanced production line can improve rice husk pellet formation rates and produce pellets in a wider range of sizes.

Sunflower seed husk pellets

Sunflower seed hulls are relatively lightweight and conventional production yields are low. However, our production equipment incorporates multiple anti-bridging devices, which enable the maximum utilization of raw materials. This process is also ideal for producing feed pellets.

peanut husk pellets

Peanut shells contain a high amount of fiber, which makes them difficult to mold. Therefore, we have configured a crusher to grind them into powder with particles smaller than 3–5 mm. This process produces compact, smooth-surfaced peanut shell pellets.

EFB pellets

This production solution features a robust system for processing raw materials. Even hard, moisture-rich empty fruit bunches can be easily turned into pellets. The resulting pellets have a hard texture, which significantly increases their calorific value and durability.

Customization of rice husk Pellet plant Capacity

To meet diverse production capacity needs, we have designed solutions with capacities from 0.6 to 40 T/H. Below are the most frequently selected capacity options, which are suitable for various rice husk pellet factory setup. If you require details of specific equipment configurations or have alternative capacity requirements, please feel free to contact us at any time.

0.6-40 T/H

rice Husk Pellet plant solution

This rice husk pellet production line delivers stable and reliable performance, consistently producing high-quality rice husk pellets. It ensures optimal quality and output, which makes it ideal for a range of biomass pellet plants. We also offer customized solutions to meet your production demands.

0.6-1 T/H

1-2 T/H

3-4 T/H

5-6 T/H

7-8 T/H

8-10 T/H

11-12 T/H

15-20 T/H

20-40 T/H

Configuration of Rice Husk Pellet Plant

Cylindrical Cleaning Screen

This equipment can efficiently filter impurities from rice husks, such as stones and sand. We have also set up a magnetic separator to work alongside it. This ensures the raw materials are clean.

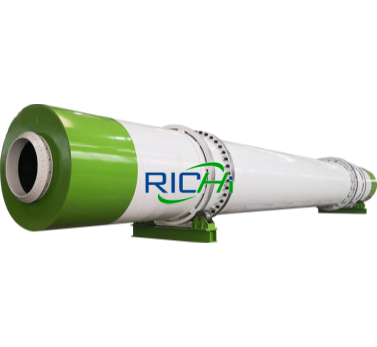

Drum Dryer

The drying drum has a large capacity and can reduce the moisture content of materials to 15%. Its double-layer interior and spiral agitator blades enable materials to dry more uniformly and quickly.

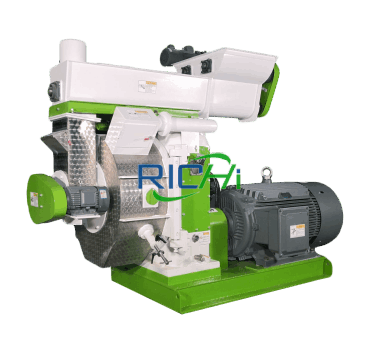

rice Husk Pellet Machine

It is the key equipment in rice husk pellet production system. We have optimized its dual-roll structure and innovative ring die. These components can adapt to most materials, achieving an optimal compression ratio.

Counterflow Cooler

Its unique structural design enables cold air and pellets to convect with each other. This ensures the pellets cool down rapidly. The device offers low energy consumption, high output and excellent cooling performance.

Rotary Classifier Screen

It can screen pellets of three different sizes while effectively removing dust particles. We offer custom designs including three-layer and two-layer screens with dual feed ports.

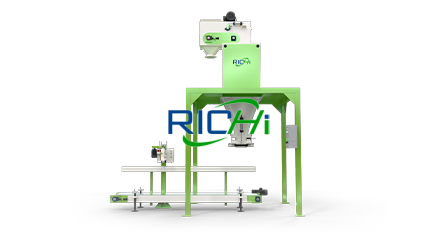

Automatic Bagging Scale

This bagging scale enables automatic weighing and packaging of pellets, ensuring precision and speed. We offer feeding designs including gravity feed, screw conveyor feed and belt feed.

The above shows the main equipment in the rice husk pellet making plant. In addition, we have designed materials conveying systems and other efficient devices. All of these offer high efficiency and energy-saving advantages. We can also provide customized designs based on your specific requirements.

GLOBAL CASES

At present, our high-efficiency rice husk pellet production solutions have gained the support of clients worldwide. Below are some real rice husk pellet plant cases. For both the sale of individual equipment and bespoke rice husk pellet production project, we guarantee flawless production services.

CUSTOMER REVIEWS

We not only provide efficient rice husk pellet plant equipment, but also offer comprehensive services. Accordingly, we have received numerous positive customer reviews. Contact us to receive your premium rice husk pellet production solution.

Click to chat with us online

VIDEOs of rice husk

PELLET plant production

We provide cutting-edge production solutions for rice husk pellet plant suppliers. They can produce high-quality rice husk pellets consistently and smoothly. Below are some videos showcasing the operation of them, which also include turnkey solutions.

Rice Husk Pellets In Production Line

Rice Husk Pellet Plant Screening Section

Rice Husk Pellet Plant In Indonesia

Frequently Asked Questions

Following many years of experience in customer service, we understand your concerns about rice husk pellet plant cost, capacity selection and others. In response, we have compiled answers to the following frequently asked questions. If you have any other questions, please feel free to contact us at any time.

What are the requirements for the raw materials used in rice husk pellet production?

+

There are three criteria that must be satisfied: appropriate moisture content, cleanliness and a small particle size. Our husk pellet production solution can perfectly address these issues.

Firstly, it is important to ensure that the raw material is clean. If the husks contain impurities such as sand, stones or metal, this will cause wear to the ring die and rollers. Therefore, it is necessary to clean them using screening equipment. Properly processing the rice husks guarantees the quality of the pellets.

Secondly, control the moisture content of the rice husks to an ideal range of 15–18%. Excessive moisture reduces the efficiency of pellet formation. If the moisture content is too low, add appropriate amounts of water or natural binders to enhance cohesion.

These standards also apply to other production system. For example, wood pellet production lines, EFB pellet production lines, straw pellet production lines, etc.

Is rice husk pellet production equipment energy consumption high?

+

Our production equipment features energy-efficient designs that reduce unit energy consumption by 20%. Typically, the drying and pelletizing processes account for most of the energy consumption.

Our drying drum offers flexible heating options. We recommend utilizing waste material combustion to reduce electricity consumption and enhance energy efficiency.

Additionally, all our pellet machines feature energy-saving motors to minimize power usage. For example, EFB pellet machine, rice husk pellet machine, wood pellet machine, sawdust pellet machine, and others. Their high-efficiency pelletization also improves the utilization of raw materials, thereby reducing costs.

What are the key maintenance points for rice husk pellet processing line?

+

Firstly, standardized operation is paramount. We provide operational training for the production line, covering techniques and maintenance essentials to help you increase production efficiency.

Secondly, it is crucial to maintain equipment in good condition for stable production. Therefore, you must regularly inspect vulnerable components such as molds and press rollers for signs of wear. If wear exceeds the threshold, replace them promptly to avoid production disruptions.

Finally, after extended operation, replenish lubricating grease promptly. At the same time, clean residual materials from the internal components to prevent blockages and corrosion.

What is the investment cost for a complete rice husk pellet plant?

+

We provide customized solutions for this production line. The specific cost of the investment depends on the scale of the production line. You can choose the most suitable option based on your capacity requirements, the conditions of your raw materials, and your desired level of automation.

Typically, the investment is relatively low for a small-scale startup production line. For large-scale, automated production lines, the investment is higher. However, high automation levels significantly reduce labor costs while ensuring more efficient production.

Additionally, our production line solutions offer a fast return on investment, providing excellent economic benefits. For specific pricing details, please feel free to contact us.

How environmentally friendly is the rice husk pellet plant solution?

+

All of the rice husk pellet plant equipment is environmentally friendly. Furthermore, this production line uses clean manufacturing processes. It significantly reduces dust and noise during production.

The rice husk pellets produced are also a clean, high-quality energy source. Their combustion emissions are low and meet multiple national environmental standards and sustainable development requirements. (View YouTube)