Pellet Mill For Sale USA

Market Conditions for Pellet Products in USA

The United States possesses abundant agricultural and forestry resources, which are sufficient to support the development of the biomass pellet industry. Furthermore, the government provide policy support for the recycling of crop residues.

On the other hand, the highly developed livestock industry in USA generates significant demand for feed pellets. Consequently, there is also a robust market for feed pellet products. Together, these factors drive the growth of the pellet manufacturing sector.

The limitations of pellet production solutions mean that high-quality pellet products remain scarce.

Although demand is high, the return on investment in the biomass pellet industry remains less than optimistic. Regular pellet production often faces issues such as low forming rates, inconsistent product quality, and short equipment lifespans.

Advanced pellet machines can resolve the current challenges.

As a leading manufacturer of pellet machines, we have earned the trust of an increasing number of American clients. In these projects of pellet mill for sale USA, our equipment not only resolves the production challenges, but also significantly boosts the economic returns.

cases of pellet mill for sale uSA

These industrial projects involve both single pellet machine for sale and complete production lines, as well as turnkey solutions. Similarly, we provide customized solutions tailored to customers’ specific production needs. Each piece of equipment delivers highly efficient, energy-saving production results.

3 t/h sawdust pellet mill for sale USA

The client operates a wood pellet plant. Their raw materials are waste wood sourced from nearby furniture factories and panel manufacturers. Consequently, we provided pellet mills and raw material processing equipment, which can efficiently produce pellets from complex wood types. This has helped the client to enhance product quality.

Annual Production Capacity : 10,000 T/a

Project Investment : $80,000

Main raw materials : sawdust, wood chips, wood shaving

Equipment Configuration : Wood Chipper, sawdust Pellet machine, Counterflow Cooler, Vibrating Screen, Automatic Bagging Scale, etc.

4-5 t/h wheat Straw pellet machine for sale USA

In this project, we delivered equipment for producing high-quality straw fuel pellets with a diameter of 8 mm. These pellets product primarily used for industrial boiler combustion and commercial heating systems. This production system features a high level of automation, significantly reducing labor costs.

Annual Production Capacity : 14,000 T/a

Project Investment : $110,000

Main raw materials : wheat straw, rice straw

Equipment Configuration : straw crusher, drum dryer, wheat straw Pellet machine, Counterflow Cooler, Rotary Grading Screen, Bagging Scale, etc.

11-12 T/H alfalfa pellet machine in uSA

This project is a turnkey solution for a grass pellet plant in USA, including comprehensive services such as production line planning, construction, equipment installation and commissioning, as well as worker training. The resulting pellets are 6 mm and 8 mm in diameter for use in ruminant animal feed.

Annual Production Capacity : 30,000 T/a

Project Investment : $200,000

Main raw materials : alfalfa, hay, corn, soybean meal

Equipment Configuration : Forage crusher, drum dryer, alfalfa pellet machine, Counterflow Cooler, Vibrating Screen, Bagging Scale, etc.

2-3 T/H rice husk pellet machine for sale USA

Our client runs a large-scale farm which uses a lot of agricultural waste as raw materials. The pelletizer we supplied can efficiently process lightweight materials into pellets, while preventing clogging. This project not only fulfills the client’s energy needs, but also generates additional economic benefits.

Annual Production Capacity : 8000 T/a

Project Investment : $60,000

Main raw materials : rice husk, rice straw, peanut shell

Equipment Configuration : Drip-Type Crusher, Cleaning Screen, rice husk Pellet machine, Counterflow Cooler, Vibrating Screen, Bagging Scale, etc.

Large-scale wood chip pellet mill USA

main material: wood chips, logs

Application: wood pellet production

Capacity: 8 T/H

miscanthus pellet mill for sale in uSA

main material: miscanthus hay, straw

Application: animal feed production

Capacity: 2.5-3.0 T/H

peanut shell pellet machine for sale USA

main material: peanut shell, rice husk

Application: fuel pellet production

Capacity: 1.8-2.0 T/H

paper pellet making machine project in USA

main material: waste paper

Application: paper pellet production

Capacity: 2-3 T/H

Video Showcase of Pellet mill for Sale USA

Solutions to Production Issues

In these projects of pellet mill for sale USA, we have helped clients resolve numerous common pelletizing issues. These include improper handling of raw materials, low production capacity, inconvenient equipment installation and operational difficulties. Through the premium solutions, our clients have enjoyed ideal production experience.

These are also common production issues that most pellet production experience.

As straw and grass contain a lot of fiber, thorough grinding is essential to prevent compromising pelletization efficiency. To meet raw material grinding requirements, we offer crushers that can produce different levels of fineness.

Typically, crop husks contain impurities when processed by machines. This often results in wear and tear to the machinery and downtime. Therefore, for husk pellet production, we will configure high-efficiency screening devices.

Raw wood usually has a moisture content of over 18%. This makes it difficult to form pellets and affects the product quality. To address this issue, we have designed an efficient drying system to improve production efficiency.

Some operators lack specialized production experience. Therefore, we have specifically provided operational training services. This training covers key points about the correct use and maintenance of equipment.

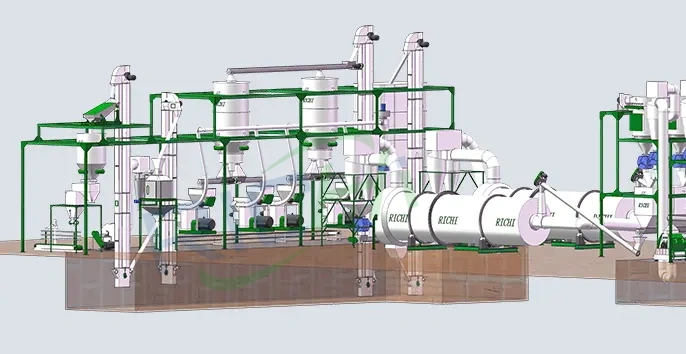

Configuration for pellet project

In addition to advanced pellet mills, we also provide complete pellet production line equipment. Below is the standard configuration for projects of pellet mill for sale USA. Beyond these primary units, we offer a range of convenient auxiliary devices to optimize your production process.

01

crushing System

This forage and straw crusher is specifically designed for high-fiber, lightweight materials such as grass, straw and rice husks. It utilizes high-hardness hammer blades to crush materials into particles ranging from 0.5 to 20 mm. Screen mesh sizes are customizable.

02

Drying System

The drum dryer features a double-layer drum and large-capacity design, enabling rapid and uniform drying. The drying result achieves a moisture content of 15%-18%. It incorporates variable frequency speed control, allowing adjustment of the drying time.

03

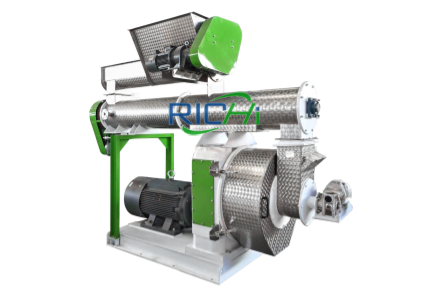

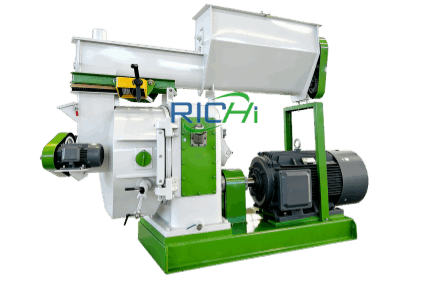

Pelletizing System

A biomass pellet mill, as the name suggests, is primarily used for producing fuel pellets. For feed applications, a conditioner is added to further gelatinize the material. Both the press rollers and ring dies are made of 42 CrMo alloy material, ensuring excellent wear resistance.

04

cooling System

This counterflow cooler rapidly cools and solidifies pellets by circulating cold air. The temperature of processed pellets does not exceed room temperature by more than 3-5°C. Its high degree of automation, combined with an octagonal structure, minimizes pellet loss.

05

Screening System

This device can separate pellets into two size classes, while removing dust particles from their surfaces simultaneously. In these project, it usually operates alongside the cooling unit. This setup increases production efficiency and saves space.

06

Packaging System

Our automatic pellet packaging machine can accurately weigh and bag products, significantly reducing labor costs. Packaging specifications range from 10 to 50 kg per unit. It supports various packaging options, including heat sealing, stitching and hybrid sealing.

The above outlines the common configurations of the pellet mill for sale USA projects. They play a vital role in different production stages. In addition, we have designed alternative models and convenient auxiliary devices. As a leading equipment supplier, we offer comprehensive production services.

Through years of project service, we have established friendly and trusting partnerships with numerous American clients. We have a thorough understanding of the specific production needs of American clients. Therefore, we have the extensive experience and capability to provide you with the ideal equipment solution.

Other Pellet machines

In addition to the pellet mill for sale USA mentioned above, we also offer other models. These robust machines deliver highly efficient pelletizing performance. The resulting pellets can be used for animal feed, fuel pellets, organic fertilizer, bedding, cat litter and other biomass applications.

corn stalk Pellet Machine

It is specifically designed for pelletizing high-quality straw pellet fuel from high fiber straw.

rice straw pellet machine

This machine produces both highly calorific clean fuel and high-quality animal feed.

hemp pellet machine

Our hemp pellet machine is ideal for meeting your high-standard feed requirements.

hay pellet machine

We offer efficient hay pellet machines that produce clean energy and high-protein feed effectively.

bagasse pellet machine

This device is designed for high-fiber bagasse materials and produces compact pellet products.

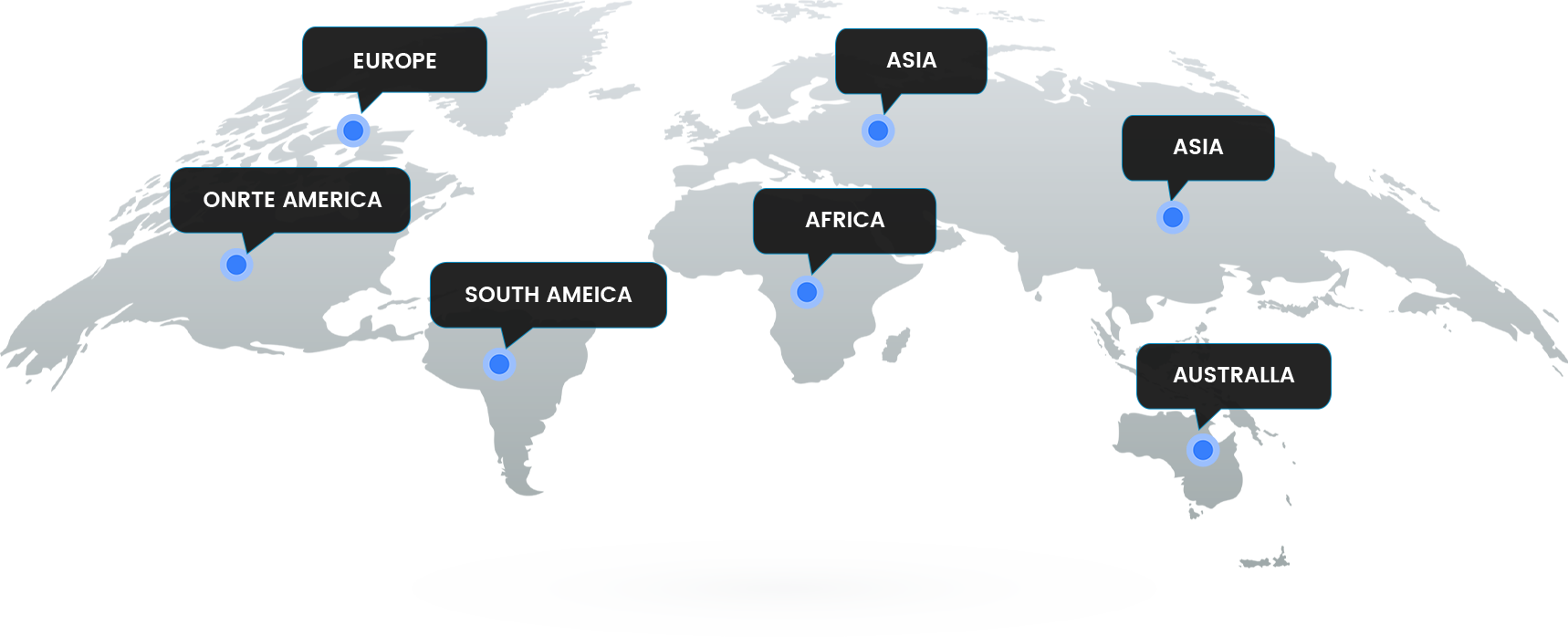

Global Cases

RICHI Services

To enhance your service experience, we has developed a comprehensive service system. This includes end-to-end solutions from equipment consultation and project planning to construction, worker training and so on. Just as we do for these projects of pellet mill for sale USA, we provide optimal support for every pellet manufacturer.

Customized service

RICHI has extensive experience in customer service. We can provide customized design solutions for pellet production. Whether you require customization of a single machine or of an entire production line, we will ensure that meets your actual requirements.

Turnkey Service

We provide turnkey solutions for industrial-grade pellet production line projects. This service covers every stage of the process, from project planning to operational implementation. All you need to do is turn the key to start producing high-quality pellets. (View YouTube)

One-Stop Service

All of our production equipment comes with a one-year warranty. We also have a global spare parts network, ensuring the rapid delivery of components such as ring dies and press rolls, which are prone to wear and tear. We also offer long-term technical guidance.

Professional Manufacturer

With the large-scale, professional manufacturing plants, our equipment is meticulously designed and rigorously tested. To date, we have completed over 2,000 outstanding pellet projects worldwide. Partner with us to propel the growth of your pellet plant.