Peanut Shell pellet Machine

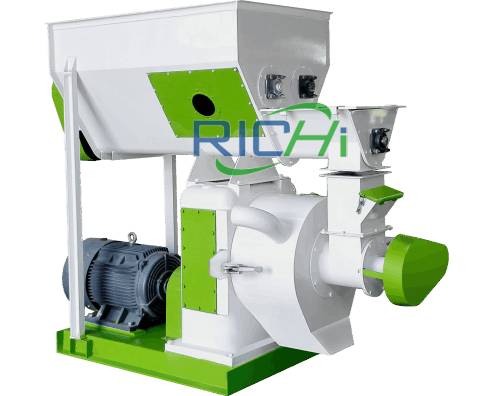

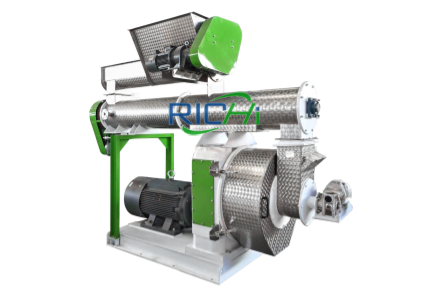

This peanut shell pellet machine is an industrial-grade machine. It efficiently processes loose peanut shells into high-quality fuel pellets. It is suitable for peanut shell pellets production with a capacity of 0.5–40 T/H. We also offer customized pelletizer to meet your diverse production needs.

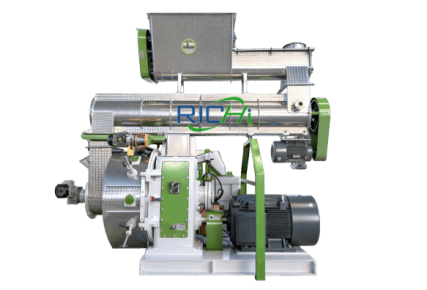

industrial peanut shell Pellet Machine

Peanut shells have high fiber content and loose texture. Therefore, conventional pelletizers face issues such as low forming rates and low output. However, our advanced, industrial-grade pellet mill resolves these problems.

High-fiber materials can cause wear and clogging in peanut shell pellet machine. Our machine incorporates multiple anti-clogging mechanisms and features alloy ring dies and rollers. This design ensures superior wear resistance and supports high-efficiency production.

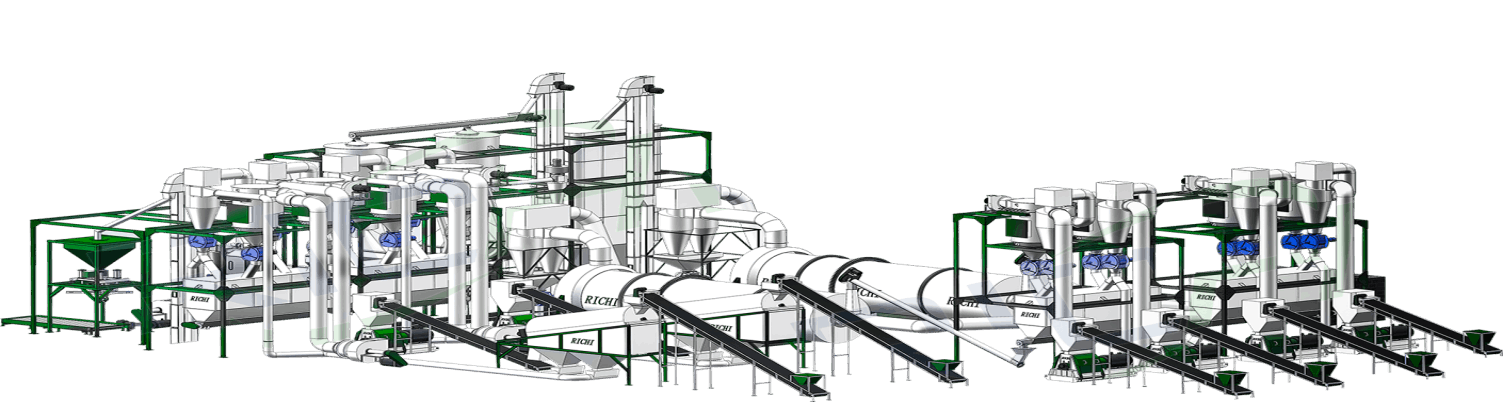

We provide standalone pelletizers and complete peanut shell pellet production line solutions. These solutions encompass raw material crushing, drying, pelletizing, cooling, screening and packaging. Each segment works in synergy with the others to deliver optimal production outcomes.

Working Process Of peanut shell pellet mill

We have optimized the pelletizing process for this equipment. The innovative dual-roll system and alloy ring die work together to produce finer, denser peanut shell pellets.

- Feeding: Powdered peanut shells enter the pelletizer via an arch-breaking feeder.

- Conditioning: The material is thoroughly mixed in an environment of high-temperature steam at 80 °C.

- Extrusion: The dual pressure rollers exert intense pressure, forcing it into the apertures of ring die.

- Forming: The cylindrical material is discharged continuously from the apertures.

- Cutting: A dual-blade mechanism slices them into uniformly sized pellets.

The above outlines the fundamental pelletizing process for this peanut shell pellet machine. We will make parameter and component adjustments tailored to your specific production needs.

Freshly produced peanut shell pellets are usually moist and soft. Therefore, direct packaging may result in pellet loss. We offer highly efficient, energy-saving cooling equipment and automatic packaging scales. If you are interested in our equipment, please provide us with your detailed production requirements.

Parameters of peanut shell Pellet Machine

| Model | MZLH 320 | MZLH 350 | MZLH 420 | MZLH 520 | MZLH 678 | MZLH 768 |

| Main Motor Power(kw) | 22 | 37 | 90 | 132 | 185 | 250 |

| Breaker Feeder Power(kw) | 2.2 | 2.2 | 3 | 3 | 3 | 4 |

| Forced Feeder Power(kw) | 0.75 | 0.75 | 1.5 | 1.5 | 1.5 | 1.5 |

| Ring Die Inner Diameter(mm) | 320 | 350 | 420 | 520 | 673 | 762 |

| Pellet Diameter(mm) | 4-12 | |||||

| Capacity(T/H) | 0.5-0.6 | 1.0-1.2 | 1.8-2.0 | 2.8-3.0 | 4-5 | 6-8 |

The above details the specific models and production capacities of this peanut shell pellet mill. Each machine has been meticulously designed to deliver sustainable fuel production. If you require any additional specifications, please do not hesitate to contact us.

Advantages of peanut shell Pellet machine

Compared to biomass pellet machine for peanut shell, our pelletizer offers significant advantages. It is not only efficient and high-performance, but also easy to operate and maintain. Its robust construction ensures an extended service life. Choose our equipment to streamline your pellet production.

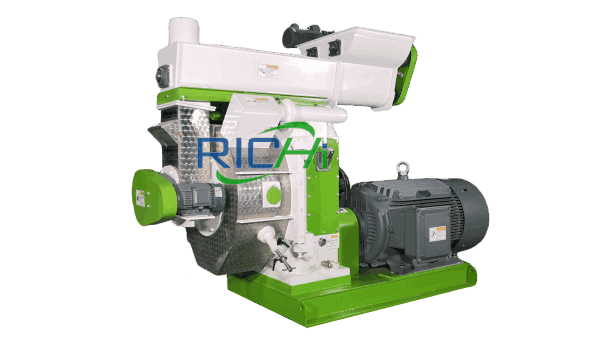

Innovative Design

RICHI peanut shell pellet machine incorporates multiple innovative designs, including anti-bridging features and an robust pellet chamber structure. These features reduce the risk of blockages and die wear.

Peanut shells are lightweight and prone to clogging equipment. Therefore, we have designed arch-breaking feeder and forced feeding device. These significantly enhance pelletizing efficiency, increase raw material utilization and boost production capacity.

This peanut shell pellet making machine accommodates a wider range of pellet sizes. Its advanced pelletizing system can produce pellets ranging in diameter from 4 to 12 mm, with lengths up to 4 to 5 times the diameter.

01

Arch-breaking feeder

The dual-spiral conveyor blades rotate in opposite directions to prevent material arching during feeding, ensuring a smooth entry into the pelletizer.

02

Forced Feeder

You can use this device to push accumulated material into the pelletizing chamber, which accelerates the granulation process.

03

Cutting Device

This allows you to adjust the distance between the cutting blade and the ring die, so you can control the length of the pellets produced.

04

Ring Die Mold

It uses a clamp-fastening installation to enhance production speed. Carburizing treatment gives it 10 times greater wear resistance.

05

Dual-Roll System

This device provides enhanced extrusion force and longer pellets. Its 2 mm-deep carburized layer provides significantly increased wear resistance.

06

Exhaust Vent

The hole allows the exhaust fan and cyclone separator to connect. It enables the high-temperature water vapor to vent promptly.

Applications of peanut shell pellet machine

This industrial-grade equipment is designed to meet diverse peanut shell pellet production needs. Whether you need high-quality fuel or animal bedding, it guarantees excellent results every time.

Processable shell Materials

You can use our machines to produce shell pellets from agricultural products such as peanut shells, rice husks and sunflower seed shells, as well as from fruit shells such as coconut and walnut shells. Its mold consistently achieve optimal compression ratios, even when using mixed raw materials.

Peanut Shell

Rice Husk

Sunflower Seed Husk

Walnut Shell

Cottonseed Husk

Coconut Husk

Available husk Pellets

Through scientifically optimized design, this peanut husk pellet machine consistently produces high-quality pellets. Its optimized rollers and dies adapt to the high ash content characteristic of peanut shells. The resulting pellets are hard and plump, meeting the highest sales standards.

The shell pellets below are suitable for production with it. Each pellet type exhibits excellent structural integrity. Contact us anytime for further details about the pelletizer.

Peanut Shell Pellets

Rice Husk Pellets

Sunflower Seed Husk Pellets

Walnut Shell Pellets

Cottonseed Hull Pellets

Coconut Shell Pellets

EFB Pellets

Palm Kernel Pellets

peanut shell Pellet Production Line

We provide industrial peanut shell pellet machines and complete peanut husk pellet production line equipment. This solution features scientifically divided processing stages, enabling the industrial production of pellets, with capacities ranging from 0.6 to 40 T/H. We also offer customized production processes and turnkey solutions.

01

Crushing

This stage is designed to crush peanut shells into 3–5 mm particles. We have designed a teardrop-shaped crusher. Compared to other models, its output has increased by 25%, making it more efficient and energy-saving.

02

Drying

If your peanut shell moisture content is around 15%-18%, this process step is unnecessary. Here comes an efficient drying drum. It is highly versatile and can rapidly and uniformly dry peanut shells and other biomass materials.

03

Pelletizing

The peanut shell pelletizer is essential for this process. Based on your raw material specifications, target capacity and pellet needs, we will provide the appropriate machinery. You can adjust the production process via the controller.

04

Cooling

This process is ideal for situations requiring rapid production. Peanut shell pellets can cool quickly through counterflow coolers. The final product’s temperature will not exceed room temperature by more than 3–5°C.

05

Screening

If you require uniform pellet size, this process can achieve this. It can screen out pellets of three different sizes. The excess material can undergo secondary pelleting. We offer multiple options for screening machines.

06

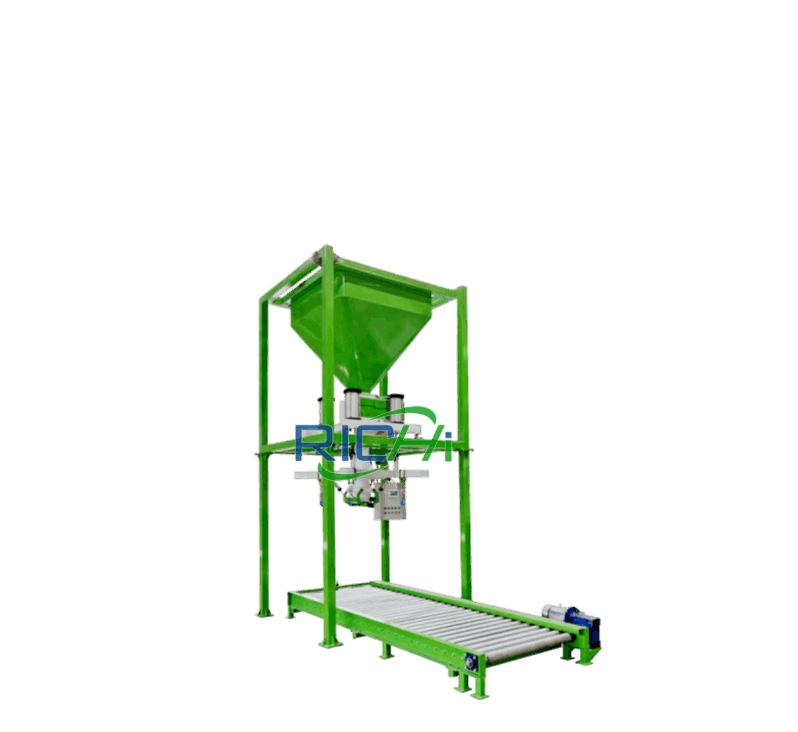

Packaging

We offer different levels of automation in packaging machines. For rapid, high-quality packaging, we recommend the fully automatic packaging scale. It enables efficient packaging and helps you save labor costs.

Application Scenarios

The peanut shell pelletizer machine and production line are suitable for various industrial applications. With advanced production capabilities and energy-saving advantages, they deliver ideal economic returns for biomass pellet manufacturers.

Additionally, our pelletizer also provides stable production performance in farms and peanut processing plants, where raw materials are plentiful.

We offer free consultations on production solutions around the clock.

We provide a one-stop service for peanut shell pellets production project.

biomass husk Pellet Plant

Farm

Rapid Customization Services

High Return on Investment

Global CASES

With our high-quality equipment and services, we have earned high praise from customers worldwide. Whether you require a single peanut shell pellet machine or a complete production line solution, our products consistently deliver exceptional performance.

Peanut Shell Pellet Mill for sale in Indonesia

The customer has a stable supply of peanut shells, and requires large-scale production of biomass pellets for sale. We provided a 2 T/H pellet mill to help improve product quality.

Biomass peanut shell pelletizer for sale in Vietnam

This client runs a biomass pellet factory. Their products are primarily sold to food processing plants and used for boiler heating. Therefore, we provided them with a high-capacity 2.8-3.0 T/H pelletizer.

Peanut Shell Pellet Production Plant in Thailand

Our client is a pellet plant that has ample supplies of peanut shells and rice husks materials. They have high requirements for pellet stability. This project’s pellet mill can produce fuel pellets with a diameter of 8 mm.

Peanut Shell Pellet Production Project in USA

The client requires a pellet machine to process mixed raw materials. The materials are peanut shells, rice husks and straw. Our industrial-grade pellet machine perfectly fits their production line.

Peanut Shell Pellet Production Project in Argentina

This project involves producing high-quality peanut shell pellets for export. We supplied the client with a complete 2.8–3.0 T/H production line. The resulting product meets sales standards in multiple regions.

Peanut Shell Pellet Plant Project in Brazil

We provided a turnkey solution for this client. The materials are peanut shells, corn cobs and corn stalks. Its target pellet diameter is 8 mm. They meet the client’s requirements for high output and quality.

Why Choose RICHI?

We offer industry-leading peanut shell pellet machine for sale.

RICHI Machinery was established in 1995, and we have remained dedicated to providing customers with the best pellet solutions. Our commitment to customer satisfaction drives us to research pellet machinery. To date, we have successfully supplied advanced peanut shell pellet maker to clients worldwide.

Drawing upon extensive customer service experience, we have a thorough understanding of your production needs and the challenges at every manufacturing stage. Consequently, we offer an integrated solution combining pre-sales and after-sales support to protect your peanut shell pellets production operations.

Our after-sales service includes a one-year warranty and a prompt response to any quality issues. To ensure rapid dispatch of components, we also maintain a global network of spare parts. If you encounter any production challenges, we will provide solutions to help you resume operations swiftly. We also offer the following services:

Free consultation Service

At RICHI, our experienced engineers and sales team offer free consultations on the peanut shell pellet making machine. We understand your production requirements and queries, so feel free to ask us any questions you have about the production solutions.

Customized Equipment Service

Should you have specific requirement for output and standard for pellets, we can provide tailored solutions to meet your needs. Our specialist technical team and large-scale manufacturing facilities can accommodate all your equipment needs.

Turnkey Production Solutions

Besides exceptional peanut shell pelletizer, our production line solutions have earned the trust and support of clients. The turnkey solutions, in particular, offer complete service including project planning, construction, equipment installation and operator training.

Other Related Production Equipment

In addition to peanut shell pellet machine, we also supply production equipment for other process stages. These include primary machinery and efficient material conveying systems. All our machines comply with multiple international environmental standards. RICHI can meet all your pellet production equipment needs.

Drip-Type Crusher

This crusher is specifically designed for crushing small materials. It features an extended hammer blade lifespan and operates quietly.

Drum Dryer

Its internal design incorporates spirally arranged paddles, along with variable-frequency speed control, enabling highly efficient drying.

Counterflow Cooler

It features a high level of automation to reduce pellets breakage. We offer the choice between pneumatic and hydraulic drive systems.

Automatic Pellet Bagging Scale

It provides fully automated weighing and uniform packaging. The sealing method options include thermoplastic sealing, seam sealing, or mixed sealing.

Other pellet machines

We have also designed other innovative pellet machines. Like the peanut shell pellet machine for sale, they offer energy-saving, eco-friendly and highly efficient performance. We are committed to providing you with premium pellet production in the long term.

EFB Pellet Machine

It features a robust pelletizing system for processing crop husks materials into pellets.

rice husk pellet machine

This machine produces both highly calorific clean fuel and high-quality animal feed.

alfalfa pellet machine

Our alfalfa pellet machine is ideal for meeting your high-standard feed requirements.

hemp pellet machine

We offer efficient hemp pellet machines that produce high-protein feed effectively.

Frequently Asked Questions

We have extensive experience in customer service. Therefore, we understand the concerns you may have when selecting a peanut shell pellet machine. We can answer questions about raw material selection, equipment features and other aspects. If you have any other concerns, please feel free to consult us at any time.

–

Does producing peanut shell pellets cause severe mold wear?

Peanut shells have a relatively high ash content, which causes wear on mold during regular production. However, our pelletizer molds have been optimized and upgraded to reduce wear levels.

Unlike other peanut shell pellet mills, our ring dies and rollers undergo a carburizing heat treatment process. This forms a hardened carbon layer 2 mm thick on their surfaces, providing wear resistance up to 10 times greater than standard molds.

Additionally, regular equipment maintenance extends mold lifespan. We recommend strictly following the operation manual.

–

Is this peanut shell pellet machine prone to clogging or malfunctioning?

If the peanut shells have high moisture content or are insufficiently crushed, it increases the risk of equipment clogging. However, under normal processing conditions, it is not prone to clogging.

To prevent this, we have designed arch-breaking feeder and forced feeding system. Furthermore, we have optimized the dual-roll structure design. These features effectively prevent clogging of the equipment.

–

How to process multiple raw materials using a peanut shell pellet machine?

Our equipment is designed for large-scale peanut shell pellet production. Therefore, we have specifically engineered multiple ring die sizes with optimized aperture combinations. By swapping out the dies, you can produce pellets from various shell materials.

We also offer other high-quality biomass pellet machines, such as wood chip pellet machine and corn stalk pellet machine. All our equipment is industrial-grade production machinery.

–

What raw materials can be mixed with peanut shells for pelletization?

Peanut shells can be mixed with the shells of other agricultural crops and fruit for pelleting. Examples include rice husks, rice straw, corn cobs and sugarcane bagasse. Combining peanut shells with other materials can enhance the combustion heat of the pellets.

Our industrial-grade peanut shell pelletizer is ideal for large-scale production. It excels at granulating mixed materials. Its innovative molds adapt to diverse blends to achieve optimal compression ratios. (View YouTube)

–

What is the ideal diameter and length for peanut shell pellets?

The ideal size of peanut shell pellets depends on their application. For industrial boiler combustion, the optimal diameter ranges from 6-8 mm, with a length of 10-30 mm. Pellets within this size range achieve more complete and stable combustion. These are also the standard specifications of biomass pellet machine for peanut shells.

Our machines can produce biomass pellets with diameters ranging from 4–12 mm and lengths reaching 4-5 times the diameter. Furthermore, we offer customized dies and ring die apertures to meet your specific pellet size requirements.