paper Pellet Machine

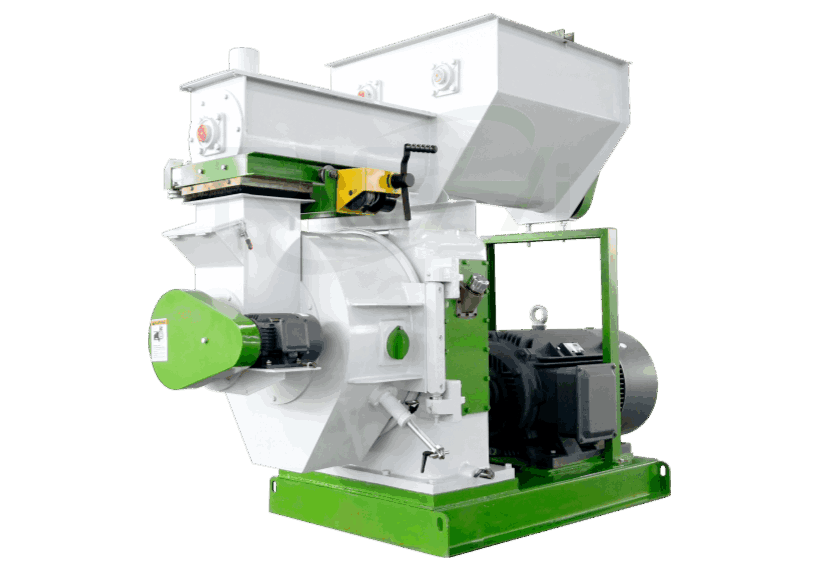

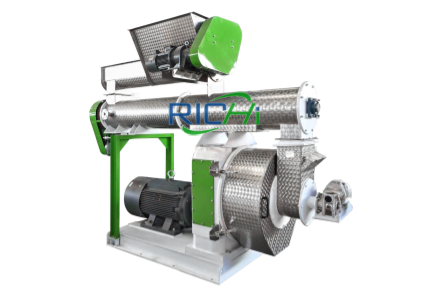

This paper pellet machine transforms waste paper into compact, uniform fuel pellets. It is ideal for large-scale waste paper recycling operations, paper making factories and biomass energy plants. With a stable output performance, it delivers a high return on investment.

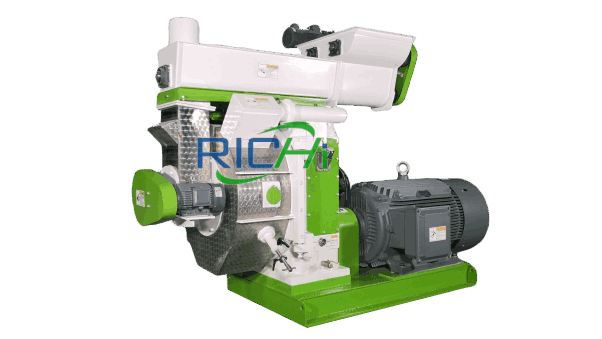

industrial paper Pellet machine For Sale

We designed this industrial paper pelletizer machine to meet the challenges of low formation rates and unstable output during waste paper pelletization. Consequently, it is better suited to high-quality pellet production.

Based on the lightweight nature of waste paper, we have optimized the design of the compression rollers and dies in this pelletizer. This enables excellent high-pressure forming performance and allows it to adapt well to the raw materials, resulting in denser pellet products.

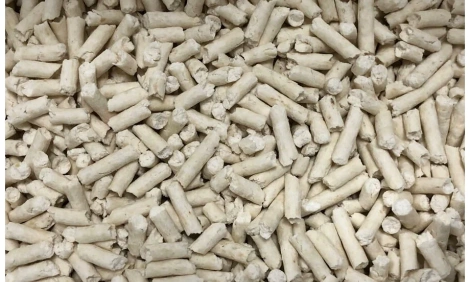

It can also produce pellets of a wider range of sizes. The finished pellets have a diameter of 4–12 mm and lengths of 4–5 times the diameter. Consequently, the equipment is suitable for a broader range of applications and meets higher-quality pellet sales standards.

Applications of paper Pellet mill

This efficient pelletizer can process a wide range of raw materials and boasts high utilization. Thanks to the advanced granulation system, it can adapt to various material ratios to achieve optimal compression, which enables the production of versatile pellet products.

Processable paper Materials

Paper pellets are usually made from waste paper, cardboard, shredded paper and dried pulp. Our paper pellet machine can process a wide range of materials, including packaging paper, paper processing trimmings, industrial paper waste and mixed paper grades. It can even handle tough corrugated cardboard with ease.

Waste Paper

Corrugated Paper

Cardboard Boxes

Newspapers

Magazine Paper

Office Paper

Kraft Paper

Packaging Paper Scrap

Pulp Residue

Printing Waste Paper

finished Paper Pellets Display

In addition to producing regular paper pellets, it has a variety of other applications. It can process other fibrous and lightweight materials into pellets. This is achieved by adjusting the appropriate dies and parameters.

Furthermore, blending waste paper with other biomass materials enables the production of high-calorific fuel pellets. These products are ideal for industrial boiler combustion, heating or power generation systems.

You can use our biomass pellet machine for paper to produce these pellet products. We also offer customization services to meet your specific requirements.

Waste Paper Pellets

Corrugated Paper Pellets

Kraft Paper Pellets

Cardboard Pellets

Packaging Paper Pellets

Pulp Fiber Pellets

Bagasse Fiber Pellets

Mixed Paper Pellets

Parameters of paper Pellet mill

| Model | MZLH320 | MZLH350 | MZLH420 | MZLH520 | MZLH678 | MZLH768 |

| Main Motor Power(kw) | 22 | 37 | 90 | 132 | 185 | 250 |

| Breaker Feeder Power(kw) | 2.2 | 2.2 | 3 | 3 | 3 | 4 |

| Forced Feeder Power(kw) | 0.75 | 0.75 | 1.5 | 1.5 | 1.5 | 1.5 |

| Ring Die Inner Diameter(mm) | 320 | 350 | 420 | 520 | 673 | 762 |

| Pellet Diameter(mm) | 4-12 | |||||

| Capacity(T/H) | 0.5-0.6 | 1.0-1.2 | 1.8-2.0 | 2.8-3.0 | 4-5 | 6-8 |

In order to help you choose, we have designed multiple models of this industrial equipment. They all deliver consistently stable production performance. Regarding the paper pellet machine price, it is determined by the specific configuration. Should you require additional parameters, we also offer customized solutions.

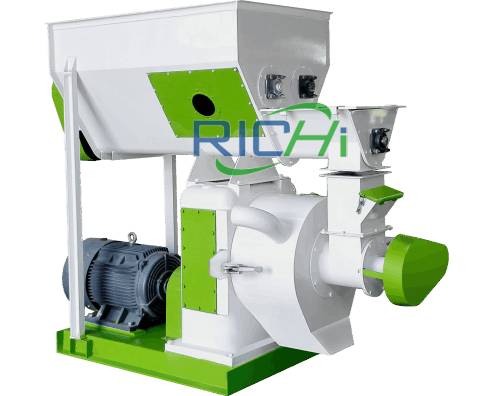

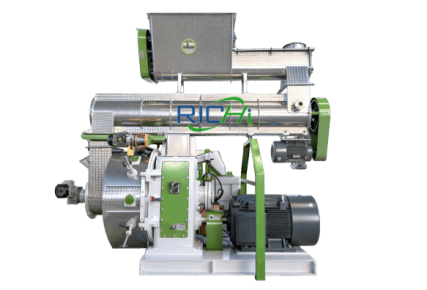

Innovative Structural Design

Our pelletizer incorporates various innovative structural designs. All of these designs meet actual production needs, enabling higher formation rates of paper pellets and ensuring more stable output. They also provide you with greater production convenience.

Waste paper materials typically contain impurities that lead to wear and tear. To address this issue, the ring dies are made of alloy steel 42 CrMo, and undergo carburizing heat treatment to make the components significantly harder.

A stable output requires a robust power system. Therefore, this paper pellet machine features a Siemens 8-pole motor and multiple specialized small motors. These components ensure more stable machine operation.

01

Arch-Breaking Feeder

Inside there are two sets of variable-frequency impellers. Their rotation ensures smooth feeding and prevents material buildup.

02

Forced Feeder

This device pushes accumulated material into the pelletizing chamber. Its dedicated motor offers greater convenience and efficiency.

03

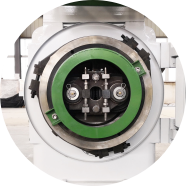

Pelletizing Chamber

Dual-roller structure meets a wider range of pellet lengths and hardness levels. Innovative ring die design enhances output per unit.

04

Exhaust Port

By installing fan and cyclone, the high-temperature steam inside can easily escape without any material leaking out.

05

Cutting Device

It adjusts and secures the cutting blade position, controlling the gap between the blades and ring die to achieve ideal pellet length.

06

Oil Injection System

This component serves as the gearbox oil filling port and features an inspection window for timely and effective gear lubrication.

Production Process of paper Pellet machine

This equipment operates at a pelletizing temperature of 80°C, which activates the binding properties of its lignin. The following outlines the basic pelletizing process. We also offer customized designs.

- Feeding: The crushed paper materials enter the pelletizer via an arch-breaking or forced feeder.

- Compression: The material passes through two sets of double-roll structures and undergoes compression under the rotational action of the ring die.

- Forming: The cylindrical material is discharged continuously through the holes of the ring die.

- Cutting: Through blade cutting, the material becomes uniformly textured pellets of the ideal size.

After undergoing the above processing steps, the paper pellets become dense and compact. Once cooled and set, they attain a stable structure.

For paper pellet manufacturer, rapid pellet cooling, screening and packaging processes are essential. Therefore, we have designed other high-efficiency equipment for paper pellet plants or other industrial-scale production lines. Feel free to contact us anytime for free consultation.

Advantages of paper Pellet machine

Our pelletizer offers simple operation and easy maintenance. It offers high efficiency, energy savings and extended service life. By investing in a pelletizer, you can produce pellets in multiple ways, maximizing your return on investment.

Global CASES

We supply paper pelletizers to manufacturers worldwide. We also provide complete production line equipment for industrial-scale paper pellet production. Whether you require individual equipment or a turnkey production line project, you will receive the most attentive service.

Paper Pellet Plant project in Mauritius

This client required the production line to turn waste cardboard boxes into fuel pellets. They had stringent pellet length standards. Ultimately, we provided a 2–3 T/H line that met the high capacity and superior quality.

Paper Pellet Maker for Sale in Poland

The client requires the production of high-calorific-value paper pellets for sale. The primary raw materials are office waste paper and cardboard boxes. We offered a 1.8–2 T/H pelletizer to produce high-quality biomass fuel.

Paper Pellet Production Project in USA

Our client operates a large-scale biomass pellet plant. They required a production line to meet stringent pellet standards. We supplied the line with a capacity of 5-6 T/H that converts waste paper into high-density pellets.

Paper Pellet Machine for Sale in Thailand

For this project, we supplied a customized, high-capacity machine. It enables the client to process waste paper and wood into high-calorific fuel pellets. With a capacity of 3 T/H, it can accept various raw material ratios.

Biomass paper Pellet making Plant in Malaysia

This project is a turnkey solution. Our client is a large-scale biomass fuel manufacturer. The raw materials are waste paper and wood chips. It features a high level of automation and has a production capacity of 10–11 T/H.

Paper Pellet making machine for Sale in Canada

The pelletizer produces boiler fuel from mixed raw materials, which include wood chips and blended paper fibers. We offer multiple ring dies, which can produce paper pellets with diameters ranging in 6-8 mm.

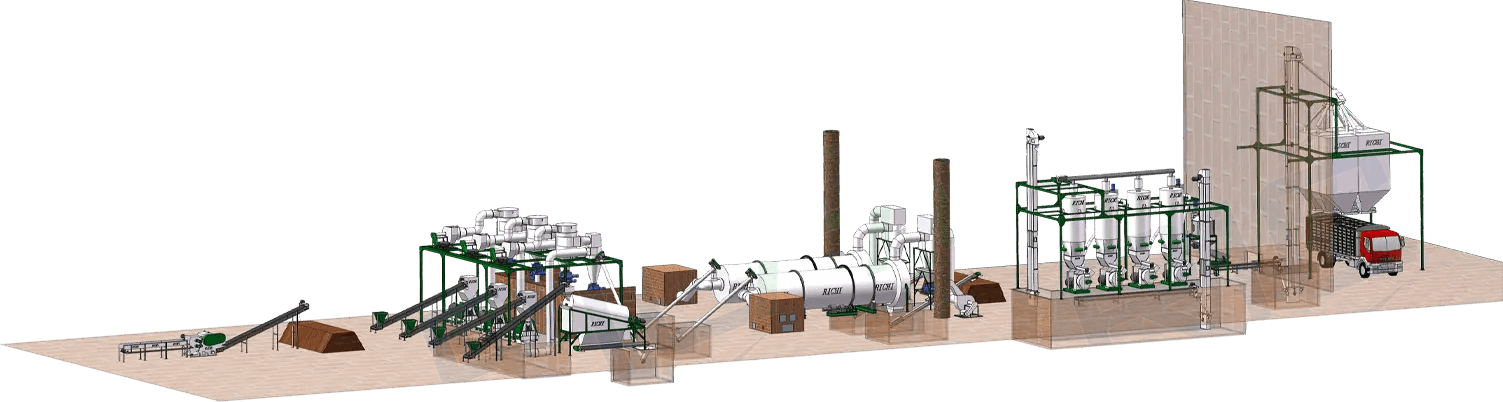

paper Pellet Production Line

We not only provide advanced paper pellet machine, but also industrial-grade production line solutions. These solutions can meet production capacity requirements ranging from 0.6 to 40 T/H. We also deliver customized solutions and turnkey project services.

01

Crushing

If your production raw material consists of untreated waste paper, we will carry out this processing stage. This treatment involves crushing the raw material to an optimal particle size of 3–5 mm.

02

Drying

This process is ideal for materials with excessively high moisture content. If your raw material exceeds 18% moisture content, we will equip a drying system to reduce it to the ideal level of 15–18%.

03

Pelletizing

The paper pellet maker plays a key role in this process section. Based on your desired pellet size and the raw material ratios, we will provide suitable ring dies to ensure optimal compression.

04

Cooling

It improves the efficiency of packaging and transporting pellet products. This process quickly cools and sets high-temperature pellets, thereby stabilizing their optimal structure and hard texture.

05

Screening

This section enables precise pellets screening and often incorporates cooling equipment to save space. It can screen up to three sizes of pellet products, and also facilitates secondary pelletization.

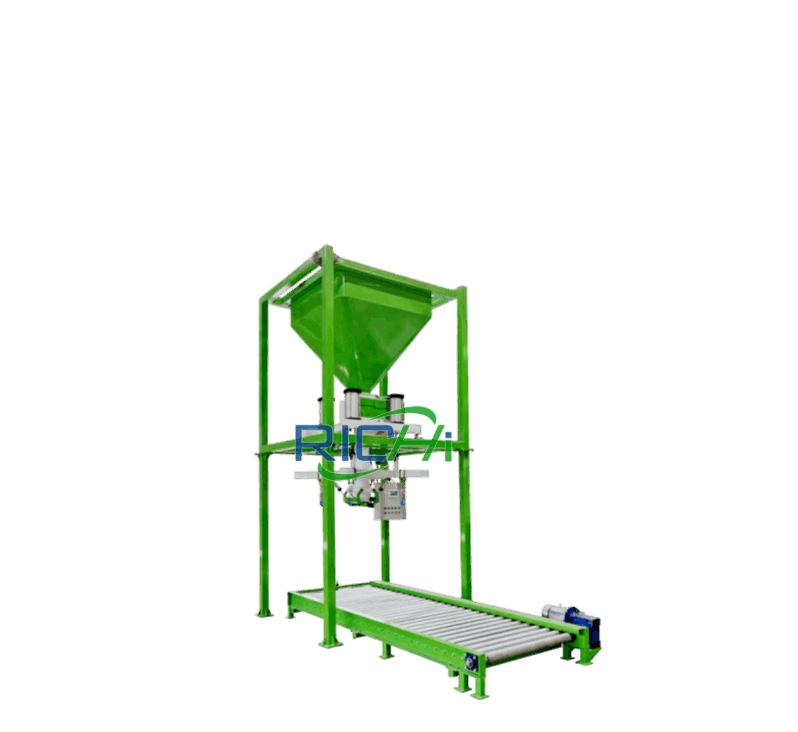

06

Packaging

If you need to improve the efficiency of packaging, while reducing costs, our highly automated packaging systems can help. This process minimizes packaging losses and labor costs for you.

Application Scenarios

This production line system features scientifically divided work sections, yet is flexible enough to meet your specific production needs. We also offer automated and disconnect production lines to fulfill your automation needs.

If you require effortless and rapid commissioning, specifically, our turnkey solution is available. It provides comprehensive, one-stop services for large-scale projects, from planning and construction to trial operation.

We offer free consultations on production equipment around the clock.

We provide a one-stop service for paper pellet production projects.

Biomass Pellet Plant

paper Processing Plant

Rapid Customization Services

High Return on Investment

Why Choose RICHI?

We offer industry-leading biomass pellet mill for sale.

As an advanced paper pellet machine manufacturer, we have consistently dedicated ourselves to providing customers with optimal pelletizing solutions. We prioritize customer satisfaction, delivering the best possible service.

Because of extensive customer service expertise, we deeply understand your production requirements. Therefore, we offer comprehensive pre-sales and after-sales support to safeguard your paper pellet production operations.

The comprehensive pre-sales service includes free consultations on paper pellet equipment. Our sales team is always available online to provide answers. We also provide attentive after-sales service, which includes the following specific services:

Long-Term Warranty

Every machine sold by RICHI comes with a one-year quality guarantee and fast shipping. For any quality issues arising during this period, you will receive prompt responses and proper resolutions.

Spare Parts Supply

We have also established a global spare parts supply network. Built upon a global system of warehouses, this network ensures the rapid shipment and timely replacement of your worn parts.

Technical Support

Beyond dedicated equipment manuals and instructional videos, we also offer installation and operational training for production line equipment, along with ongoing online technical guidance.

Other Related Production Equipment

In addition to paper pellet machine, we provide complete paper pellet production line equipment. Below are the core configurations for the main process sections. In addition, we offer convenient and efficient auxiliary devices, such as material conveying systems and storage bins. You can rely on us to find the most suitable equipment solutions.

Water Drop Crusher

It can crush materials no larger than 5 cm in size, producing crushed particles with diameters ranging from 0.5 to 20 mm. The screen mesh size is customizable.

Drum Dryer

This unit features a double-layer drying cylinder and spiral agitator blades. It dries high-moisture raw materials to the desired level of 15%-18%.

Cooling Machine

It has a high level of automation, using cold air circulation to cool and set the pellets. The octagonal structure prevents pellet breakage.

Packaging Scale

It provides fully automated weighing and uniform packaging. You may select thermoplastic, stitching, or hybrid sealing methods.

Other pellet machines

Similar to our paper pellet machine, we also offer other industrial biomass pellet machines. These are equally well-suited to production lines with capacities ranging from 0.6 to 40 T/H. They can produce clean fuel, animal feed, organic fertilizer, bedding and other biomass pellet products.

bamboo Pellet Machine

It features a robust pelletizing system for processing high fiber bamboo materials into pellets.

rice husk pellet machine

This machine produces both highly calorific clean fuel and high-quality animal feed.

hay pellet machine

Our practical hay pellet machines can produce premium livestock feed and fuel pellets.

alfalfa pellet machine

Our alfalfa pellet machine is ideal for meeting your high-standard feed requirements.

Corn stalk pellet machine

We offer efficient corn stalk pellet machines that produce high calorific fuel pellets.

Frequently Asked Questions

We fully understand your concerns when selecting an investment paper pelletizer. Therefore, we have compiled this detailed guide covering equipment selection, and suitable applications. Alternatively, you can tell us about your production requirements and we will provide a bespoke solution.

–

What other materials can the paper pellet machine process besides waste paper?

Our pelletizer is industrial-grade equipment with robust pelletizing capability. It is equally suitable for processing other paper fibers or lightweight materials. Examples include corrugated cardboard, paper cartons and dried pulp. Even mixed paper grades can be easily pelletized.

If you require pellets with a higher calorific value, we recommend blending in appropriate amounts of wood chips. When raw materials undergo proper processing, this pelletizer achieves stable compression ratios, producing denser, high-quality fuel.

We also offer specialized, high-efficiency pelletizers for processing other biomass materials. These include wood chip pellet machine, rice straw pellet machine, rice husk pellet machine, wheat straw pellet machine and others.

–

What are the applications of paper pellets?

Paper pellets are made from waste paper, cardboard boxes, corrugated cardboard, and other paper materials. Essentially, they are a low-cost biomass material. Therefore, the primary use of paper pellets is as biomass fuel for boilers, heating systems, and power generation systems.

Additionally, paper pellets produced through specialized processes can serve as eco-friendly filling materials. Advantages include lightweight properties and high water absorption capacity. Whatever the intended application, our equipment can effortlessly produce paper pellets to meet these needs.

–

How to select the right paper pellet machine model?

Standard paper pelletizers typically have a production capacity of 0.5–5 T/H. However, our pelletizers offer a broader capacity range, with customized equipment capable of reaching 6–8 T/H. The small-scale industrial production projects may prefer 0.5–2 T/H paper pelletizers.

For large-scale projects, multiple units can be connected in parallel to achieve exponential capacity increases. Of course, a complete production line solution is the most convenient option. This includes raw material pre-treatment and pellet product cooling and packaging systems. You can select the option that best matches your target output. (View YouTube)

–

When is it necessary to use crushing and drying equipment?

The ideal raw material size is powder within 3-5mm. If your raw material exceeds this size, crushing is required. This is particularly important for harder paper materials such as cardboard boxes, corrugated paper and packaging paper.

Additionally, the ideal moisture content of the raw material is 15–18%. Paper materials are prone to moisture absorption and water retention. If your raw material has a high moisture content, we recommend adding a drying unit. We also offer complete paper pellet plant solutions to enhance production efficiency and convenience.

–

How to determine if investing in paper pellet production is truly suitable?

This primarily depends on your raw material supply, end-use applications, and production capacity. If you have a stable source of paper-based raw materials and clear sales channels or applications, you may consider long-term investment planning.

Our equipment is designed for industrial-scale production with a minimum capacity of 0.5 T/H. Paper pellet production at or above this capacity consistently delivers stable returns on investment. We recommend conducting a professional technical assessment before enquiring about equipment.

We also offer other high-efficiency pelletizing equipment, such as peanut shell pellet machine, hemp pellet machine, miscanthus pellet machine, and more. Should you require a customized solution, please feel free to contact us at any time.