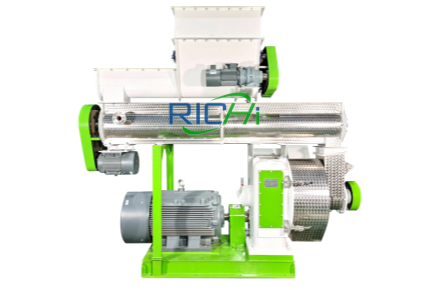

Miscanthus Pellet Mill

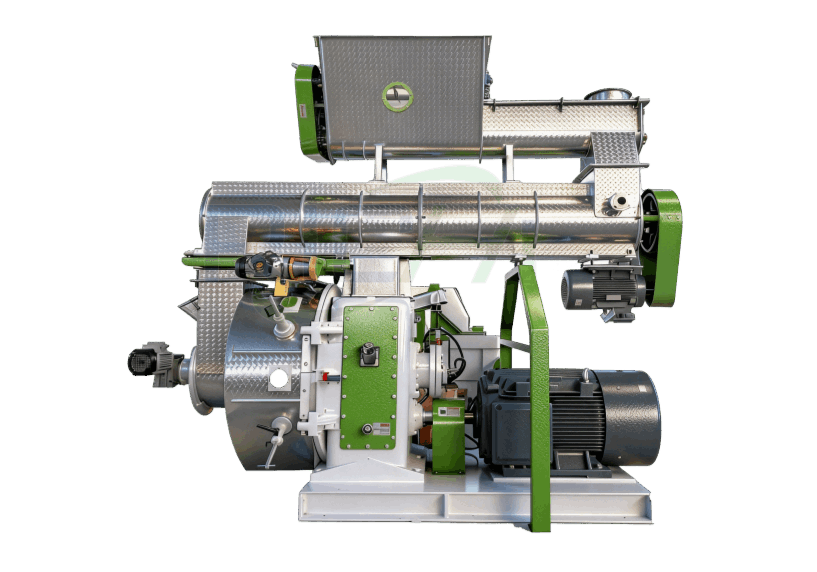

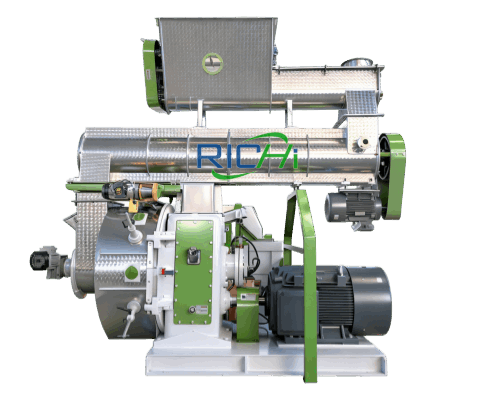

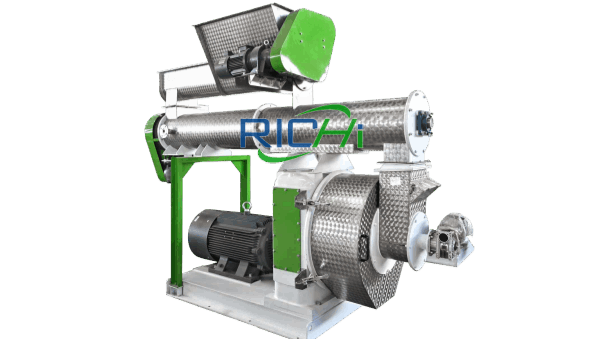

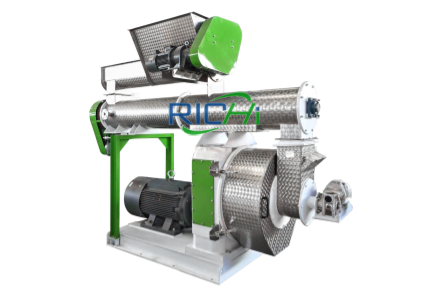

This miscanthus pellet mill is designed to process miscanthus into high-quality biomass pellets, animal feed or bedding. It features a robust pelletizing system and wear-resistant mold, which can produce pellets ranging in diameter from 4 to 12 mm. We offer multiple capacity options and customized solutions.

miscanthus pellet mill for sale

Miscanthus has a high fiber content. For this reason, conventional miscanthus pellet maker often experience problems such as frequent blockages and low pellet formation rates. However, our pelletizer features a robust pelletizing system that effectively prevents these problems.

In order to address the issue of blockages caused by high-fiber pampas grass, we have designed an anti-blocking device. This device has two anti-clogging feed ports to ensure smooth material feeding. Its dual-roller structure effectively compresses the material to prevent die blockages.

Both the ring die and rollers are crafted from alloy steel 42 CrMo and undergo carburizing treatment. Their surfaces feature a hardened 2 mm-deep carbonized layer, significantly enhancing wear resistance. These features enable the pelletizer to effortlessly process miscanthus, even with a high silica content.

Parameters of miscanthus Pellet Machine

| Model | CZLH320 | CZLH350 | CZLH420 | CZLH520 | CZLH678 | CZLH768 |

| Main Motor Power(kw) | 22 | 37 | 90 | 132 | 185 | 250 |

| Breaker Feeder Power(kw) | 2.2 | 2.2 | 3 | 3 | 3 | 4 |

| Forced Feeder Power(kw) | 0.75 | 0.75 | 1.5 | 1.5 | 1.5 | 1.5 |

| Ring Die Inner Diameter(mm) | 320 | 350 | 420 | 520 | 673 | 762 |

| Pellet Diameter(mm) | 4-12 | |||||

| Capacity(T/H) | 0.5-0.6 | 1.0-1.2 | 1.8-2.0 | 2.8-3.0 | 4-5 | 6-8 |

The above outlines the model classifications and specific parameters for this industrial miscanthus pellet mill. This serves only as a basic reference, of course. If you require additional parameters, we can provide customized equipment. Please feel free to contact us for a free consultation.

Applications of miscanthus Pellet mill

Our miscanthus pelletizer are ideal for large-scale biomass pellet or animal feed production. Our clients include biomass pellet plants, clean energy manufacturers, feed mills, large-scale farms.

Processable Raw Materials

This equipment is designed specifically for processing high-fiber raw materials. It can handle biomass grasses, crop straw and mixed-ratio materials. Using this pellet machine gives you greater flexibility in choosing raw material ratios.

Miscanthus

Switchgrass

Elephant grass

alfalfa

hay

oat grass

The Perfect Pellets

The miscanthus pellet mill can be used to produce a variety of biomass pellets. For example, you can use it to transform miscanthus into high-quality fuel, feed or plant-based cat litter. It consistently delivers stable and efficient production.

These superior pellet products meet higher market demands. They can be used for boiler combustion, power generation, district heating and residential heating. When used as animal feed, they also deliver excellent nutritional outcomes.

Below are pellet products manufactured using this biomass grass pellet machine. Should you require such a high-efficiency pelletizer, feel free to inquire at any time.

miscanthus Pellets

Switchgrass Pellets

Elephant grass Pellets

Oat Grass Pellets

Timothy Grass Pellets

alfalfa Pellets

hay Pellets

Ryegrass Pellets

Advanced Structural Design

Our professional technical team has implemented multiple technical upgrades to the equipment. As a result, this miscanthus pellet mill prevents common production issues and delivers smooth, efficient production.

This equipment can meet your requirements for pelletizing mixed raw materials by installing a conditioner. Our conditioner is made from 304 stainless steel, enabling higher conditioning temperatures.

To ensure efficient and stable operation, it is fitted with a Siemens 8-pole motor. Dedicated motors are also fitted at both feed ports to enable reliable operation of the variable-frequency impeller feeder and forced feeder.

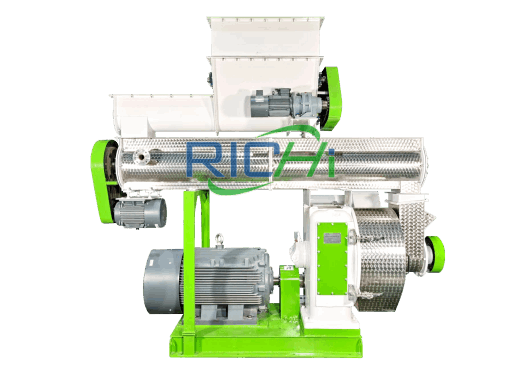

01

Arch-Breaking Feeder

Also known as a variable-frequency rotor feeder, it provides smooth feeding by rotating spiral paddles, which can be adjusted for speed.

02

Forced Feeder

The device allows you to easily push the accumulated material into the pelletizing chamber, thereby accelerating the process.

03

Cutting Device

This device can be installed in two sets. It adjusts the gap between the internal blades and the ring die to achieve different pellet lengths.

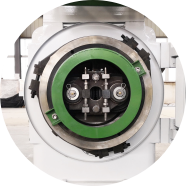

04

Pelletizing Chamber

The ring die is secured with forged clamps for enhanced durability. The dual internal rollers deliver superior compression force.

05

Observation Port

Through this port, you can monitor the pelletizing process inside and check for material buildup, enabling timely adjustments.

06

Exhaust vent

By installing a fan and cyclone, the high-temperature water vapor inside can be easily vented without material leaking out.

Working Process Of miscanthus pellet machine

The pelletizing temperature is 80°C, which thoroughly conditions the material to enhance its forming rate. We will adjust component configurations and parameters according to your specific operational needs.

- Feeding: Powdered miscanthus enter the pellet mill via a variable frequency feeder.

- Conditioning: The material undergoes thorough gelatinization in the conditioner before entering the pelletizing chamber.

- Extrusion: The dual pressure rollers exert intense pressure, forcing them into the apertures of ring die.

- Forming: The cylindrical material is discharged continuously from the apertures.

- Cutting: The blades on the inner wall of the pelletizing chamber cut them into uniformly sized miscanthus pellets.

The above describes the production process of this miscanthus pellet mill. If your target product is fuel pellets, a conditioner will not be required.

These finished miscanthus pellets require time to cool and set. If you require a specific production rate, we can also provide high-efficiency cooling and screening equipment, which will help you quickly proceed with subsequent processing tasks.

Advantages of miscanthus Pellet mill

As a professional miscanthus pellet machine supplier, our equipment boasts multiple advantages. It not only efficiently meets pellet requirements, but also comes with a stable and simple structure. By choosing our equipment, you can expect a rapid return on investment.

Global CASES

We have extensive experience of working on pellet production projects. Our miscanthus pellet mill and production line solutions have earned the trust and support of customers worldwide. Whatever solution you choose, we will deliver equipment and services that meet your satisfaction.

Miscanthus Pellet Maker for Sale in Australia

A customized piece of equipment plays a vital role in this project. It is an efficient pelletizer to produce plant-based cat litter pellets. The pellets are made from a base material of miscanthus, blended with cassava and rice husks.

Biomass Miscanthus Pellet Production Project in Canada

In this case, the client required a pellet mill that could process miscanthus and wheat straw. Our equipment can handle these high-fiber, lightweight materials effectively, delivering optimal pelletization results.

Miscanthus Pellet Making Machine for Sale in the USA

The client is a feed mill that requires a pellet machine capable of producing 6mm-diameter feed pellets from miscanthus, alfalfa and grains. Our pellet mill delivers stable output with a capacity of 1.8-2.0 T/H.

Miscanthus Pellet Plant project in Finland

This is a turnkey project for a grass pellet plant. The raw materials are miscanthus, rice straw, wheat straw and others. We provided the client with highly automated miscanthus pellet plant equipment.

Commercial Miscanthus Pellet Machine for Sale in Malaysia

The main raw materials for this project are miscanthus, palm shells and rice husks. We offer a pelletizer with capacity of 2.8–3.0 T/H. It effectively processes mixed raw materials to produce high-quality fuel pellets.

Small Miscanthus Pelleting Mill for Sale in Poland

Our client operates a cultivation farm requiring biomass fuel production primarily from miscanthus. This 0.5-0.6 T/H pelletizer enables the client to process various raw materials and offers additional economic benefits.

Why Choose RICHI?

We offer industry-leading miscanthus pellet mill for sale.

RICHI Machinery established since 1995, and we have consistently dedicated ourselves to providing customers with optimal straw pelletizing solutions. We prioritize customer satisfaction, delivering the best possible service.

Because of extensive customer service expertise, we deeply understand your production requirements. Therefore, we offer comprehensive pre-sales and after-sales support to safeguard your miscanthus pellet production operations.

The comprehensive pre-sales service includes free consultations on rice straw pellet equipment. Our sales team is always available online to provide answers. We also provide attentive after-sales service, which includes the following specific services:

Long-Term Warranty

Every machine sold by RICHI comes with a one-year quality guarantee and fast shipping. For any quality issues arising during this period, you will receive prompt responses and proper resolutions.

Spare Parts Supply

We have also established a global spare parts supply network. Built upon a global system of warehouses, this network ensures the rapid shipment and timely replacement of your worn parts.

Technical Support

Beyond dedicated equipment manuals and instructional videos, we also offer installation and operational training for production line equipment, along with ongoing online technical guidance.

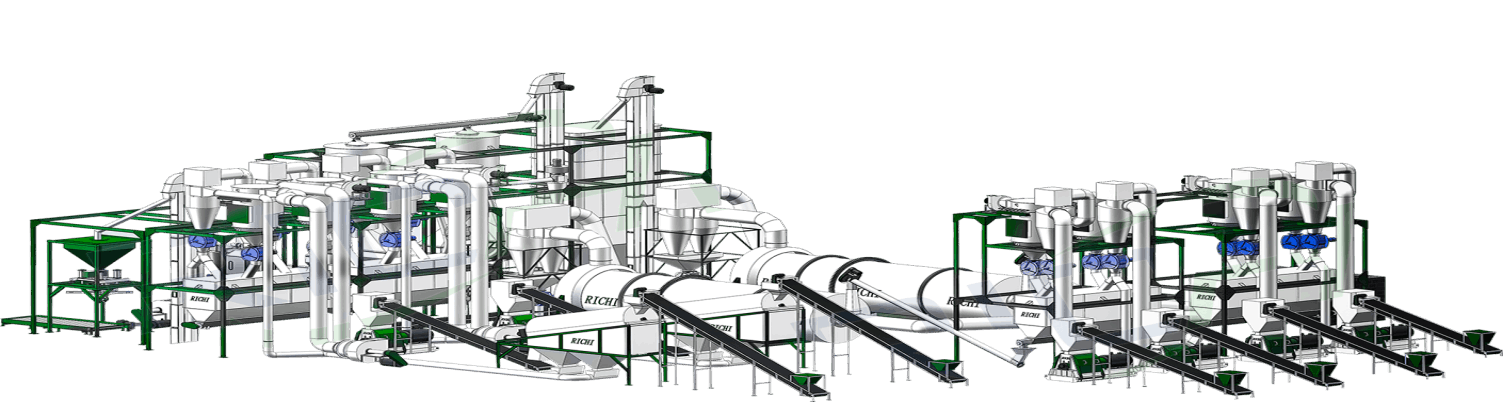

miscanthus Pellet Production Line

Miscanthus pellet mill is the key equipment in this grass pellet production line. We provide industrial-grade production line equipment with a production capacity ranging from 0.5 to 40 T/H. Moreover, we offer customized solutions and turnkey services.

01

Crushing

If your raw material consists of intact miscanthus fibers, this process can pulverize it into particles with a diameter of 3-5 mm. Our crushing equipment efficiently grinds the material and removes any metallic impurities.

02

Drying

The section is capable of efficiently drying fresh or high-moisture materials. Passing through this dryer reduces material moisture to the ideal level of 15%-18%. You can also adjust the drying time for the raw materials as required.

03

Pelletizing

Our powerful pellet mill primarily functions in this stage. Accordingly, we will provide suitable models and configurations based on needs. This ensures both a high pellet formation rate and premium quality.

04

Cooling

This section is ideal for rapidly cooling the structure of pellets, thereby increasing the production efficiency of pelets products. Our highly automated cooling equipment quickly cools pellets while preventing damage.

05

Screening

If you require pellet screening in different sizes, we can provide the low-loss, precision screening machinery. It simultaneously removes excess material for secondary granulation, thereby reducing costs.

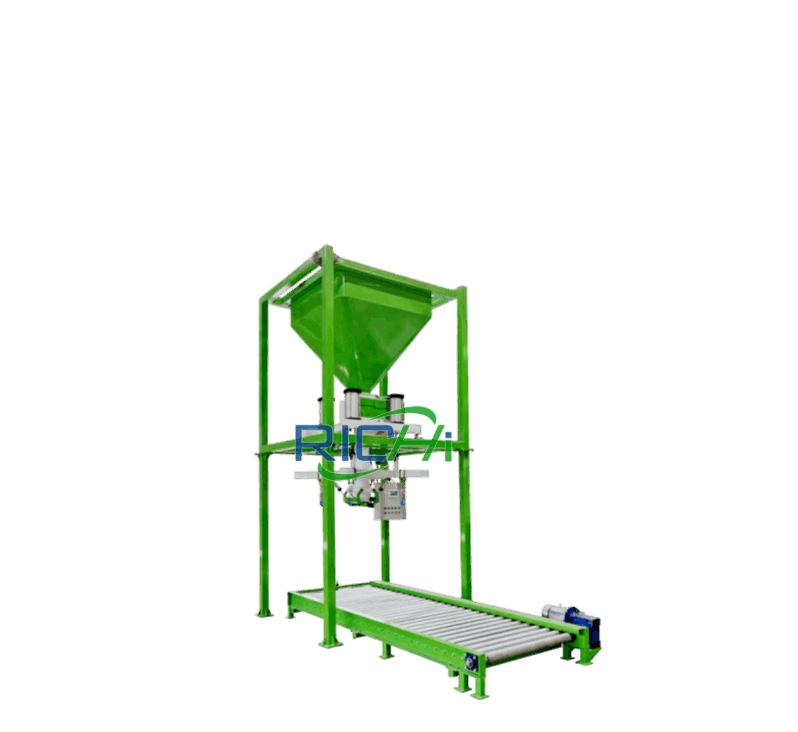

06

Packaging

For large-scale pellet manufacturers, an efficient automated packaging line is essential. This process section will ensure consistent product packaging specifications, while reducing labor costs and pellet loss.

Application Scenarios

This miscanthus pellet production line is a high-quality industrial solution. It can produce pellets from grass and straw. For example, biomass fuel pellets, feed pellets and cat litter pellets.

Therefore, it is ideal for large-scale biomass pellet plants, grass pellet plants, feed mills and large farms. We can also tailor the process configuration to your specific production requirements and raw material characteristics.

We offer free consultation on production solutions around the clock.

We provide a one-stop service for miscanthus pellet production projects.

biomass Pellet Plant

grass pellet plant

Rapid Customisation Services

High Return on Investment

Other Related Production Equipment

Like the miscanthus pellet mill, we also provide complete miscanthus pellet production line equipment. All of our equipment features meticulously design. They share the same high-efficiency, energy-saving features, providing you with maximum production convenience.

raw material Crusher

Designed for crushing high-fiber grass and straw, it produces shredded material with a diameter of 5–20 mm. A magnetic plate can also be fitted to attract impurities.

Drum Dryer

It features a double-layer drying drum and agitator blades to enable the rapid and uniform drying raw materials. You can also adjust drying time based on the moisture content of material.

Counterflow Cooler

This cooler achieves rapid pellet shaping through convection between cold air and pellets. Its octagonal design also prevents pellets from breaking.

Packaging Scale

It provides fully automated weighing and uniform packaging. The sealing options include thermoplastic sealing, seam sealing, or mixed sealing.

Other pellet machines

As a leading supplier of biomass pellet machines, we also offer other high-efficiency pelletizers. Like our miscanthus pellet mill, they can also produce biomass fuel, animal feed, animal bedding, organic fertilizer, and much more. Please feel free to contact us for a free consultation.

alfalfa pellet machine

Our alfalfa pellet machine is ideal for meeting your high-standard feed requirements.

hay pellet machine

We offer efficient hay pellet machines that produce clean energy and high-protein feed effectively.

hemp pellet machine

This pelletizer can process high-fiber hemp materials, producing premium animal feed or fuel.

rice straw Pellet Machine

It can efficiently pelletize high-fiber straw into high-quality fuel or animal feed.

peanut shell pellet machine

The machine produces both highly calorific clean fuel and high-quality animal feed.

Frequently Asked Questions

We understand your concerns when investing in equipment. Therefore, we have compiled these FAQs about miscanthus pellet making machine to help you make an informed decision. For any questions not covered here, feel free to contact us anytime for answers.

–

What are the applications of miscanthus pellets?

As biomass pellets, they serve as a clean, high-quality energy fuel. They are ideal for boiler combustion, domestic and district heating, industrial power generation, and more. They also play a significant role in the production of organic fertilizer, crop substrates and similar applications.

Because of the excellent water absorption capacity, they are also high-quality animal bedding or cat litter. Furthermore, its high fiber content aids digestion and nutrient absorption in animals. Consequently, miscanthus pellets can be used as animal feed.

Some customers also use them in the environmental sector. For example, blending them with agricultural residues such as wood shavings, straw and rice husks increases their calorific value while reducing production costs.

–

Can the miscanthus pellet mill process 100% raw miscanthus material?

Certainly. This equipment can efficiently process fibrous grasses and has excellent wear resistance. It not only efficiently pellets mixed materials, but also produces high-quality pellets from pure miscanthus.

Miscanthus also contains lignin identical to that found in wood chips. This component ensures superior bonding and moulding under high-temperature steam conditions. Accordingly, our equipment operates in a high-temperature steam environment of 80°C. Under standard processes, it significantly increases pellet formation rates.

–

What types of mixed biomass can this miscanthus pellet machine process?

It can pelletize biomass materials in various mixed ratios, depending on your desired application. We will configure the dies, rollers and other components, as well as fine-tuning the optimal parameters, based on your raw material characteristics.

If you require mixed-ratio fuel pellets, common blending materials include miscanthus grass, wood chips, straw and rice husks. This enhances their calorific value while reducing raw material costs.

Additionally, mixtures of grass, rice husks and soybean residue can be used to produce plant-based cat litter pellets. This improves pellet quality and enhances water absorption properties.

We also supply other pelletizers that can efficiently process mixed biomass materials. These include wood chip pellet machine, corn stalk pellet machine, wheat straw pellet machine, among others. (View YouTube)

–

What is the production capacity of this miscanthus pellet mill?

Our pellet mills are available in multiple models and production capacities. The minimum output for a single unit is 0.5 T/H. On the other hand, it can achieve a maximum output of 8 T/H. For large-scale production lines, you may also employ a configuration of multiple pelletizers operating in parallel to enhance production efficiency.

This miscanthus pelletizer is suitable for production lines with a capacity of 40 T/H or more. If you require a bespoke equipment solution, please contact us for further details.

–

Can the miscanthus pelletizer machine produce pellets for different applications?

Our equipment is an industrial-grade pellet mill, so that it can produce pellets for multiple purposes. These include fuel pellets, animal feed, organic fertilizer and cat litter. This is easily achieved by adjusting the ring die and parameters.

If you require a multi-purpose, high-efficiency pellet mill, this model will maximize your return on investment. Similarly, we offer other biomass pellet machines with high returns on investment. These include rice husk pellet machine and EFB pellet machine, among others.