hemp Pellet Machine

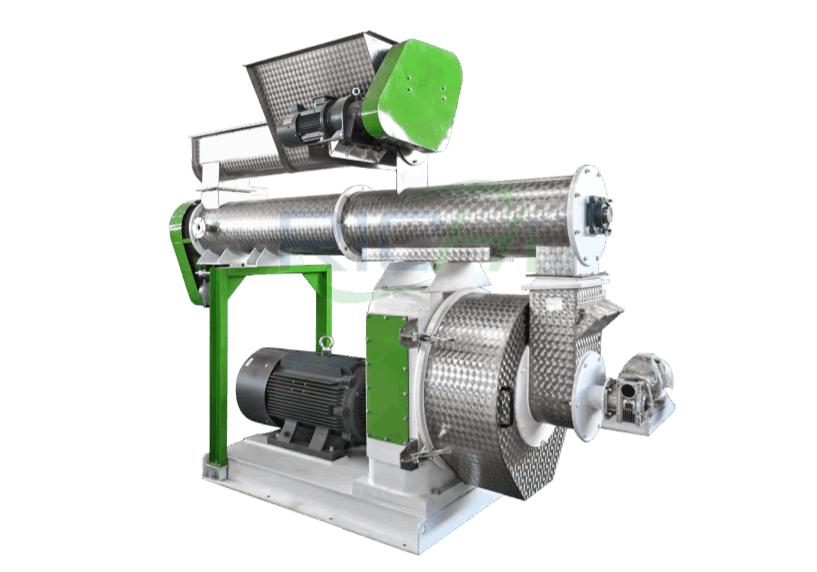

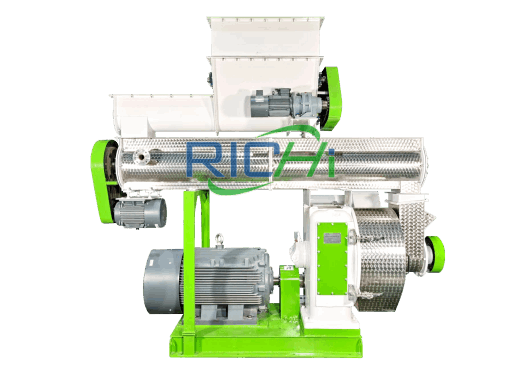

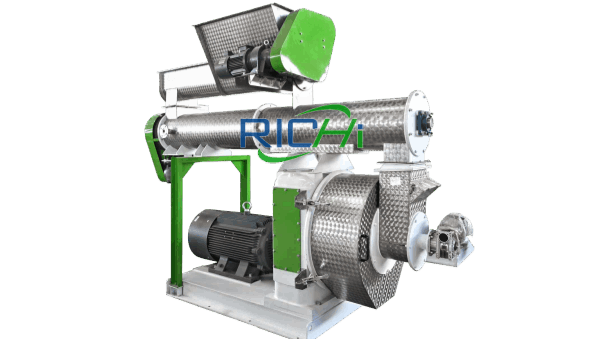

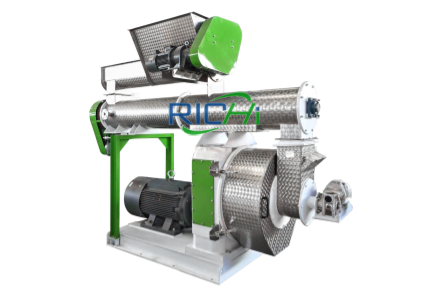

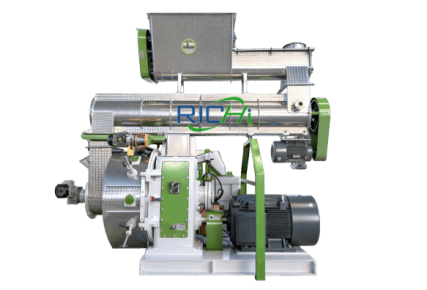

This hemp pellet machine is specially designed for pelletizing high-fiber hemp materials. It features excellent anti-entanglement and anti-clogging systems. Thus, it is ideal for producing high-quality fuel pellets, animal feed and bedding. We also offer customized equipment solutions.

industrial hemp Pellet Machine For Sale

RICHI hemp pellet mill is an advanced industrial-grade machine. It features robust anti-clogging feeding and pelletizing system. This makes it suitable for stable hemp pellet production across various industrial scales.

This pelletizer is designed to process hemp raw materials with high-fiber content efficiently, including hemp stalks, hemp fibers and hemp straw. By utilizing high-strength rollers and an innovative ring die, it can compress low-density materials into compact, uniform fuel pellets.

In addition, it is equally capable of producing hemp feed pellets. By adding a conditioner and adjusting parameter ratios, it can produce ideal feed. The hemp feed pellet machine allows mixing hemp with other raw materials for pelletization. Examples include alfalfa, corn, soybean meal, and more.

Innovative Design

Our hemp pellet machine incorporates a variety of innovative designs. As well as a forced feeding mechanism, it features a dual-roller structure and optimized mold for the ideal compression ratio. These designs ensure efficient, stable, large-scale pellet production.

In response to the issue of low density hindering pellet formation in hemp, we have designed a dual-roll structure. This system generates a greater compression force, thereby improving pellet formation rates.

Similarly, the ring die incorporates multiple innovative designs. These designs primarily enhance its wear and corrosion resistance, while also increasing output per unit.

01

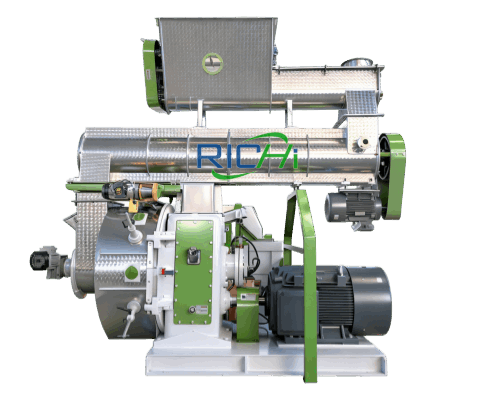

Arch-Breaking Feeder

This design includes two sets of spiral agitator blades and a special motor. They stir the material through counter-rotation to achieve smooth feeding.

02

conditioner

The conditioner is made of 304 stainless steel, which offers high-temperature and corrosion resistance. Its enlarged design increases capacity.

03

Forced Feeder

This device allows you to push accumulated material into the granulation chamber, thereby increasing production efficiency and reducing waste.

04

Ring Die Mold

It is made of 42 CrMo alloy steel and undergoes carburizing heat treatment to enhance durability. Its rationally arranged apertures increase output.

05

Dual-Roll System

Its surface features a hardened carbonized layer, enabling to handle high-fiber hemp effectively. The powerful compaction effect increases forming speed.

06

Exhaust vent

The small hole above the chamber connects a fan and cyclone. This effectively vents high-temperature steam and avoids sucking out material.

Parameters of hemp Pellet Machine For Sale

| Model | CZLH320 | CZLH350 | CZLH420 | CZLH520 | CZLH678 | CZLH768 |

| Main Motor Power(kw) | 22 | 37 | 90 | 132 | 185 | 250 |

| Breaker Feeder Power(kw) | 2.2 | 2.2 | 3 | 3 | 3 | 4 |

| Forced Feeder Power(kw) | 0.75 | 0.75 | 1.5 | 1.5 | 1.5 | 1.5 |

| Ring Die Inner Diameter(mm) | 320 | 350 | 420 | 520 | 673 | 762 |

| Pellet Diameter(mm) | 4-12 | |||||

| Capacity(T/H) | 0.5-0.6 | 1.0-1.2 | 1.8-2.0 | 2.8-3.0 | 4-5 | 6-8 |

The above details the specific parameters and production capacity of the RICHI hemp pellet mill. You can choose the most suitable model based on your requirements. We also offer customization services for other specialized models. Please feel free to contact us to discuss your requirements.

Advantages of hemp Pellet mill

As a professional hemp pellet machine supplier, our equipment boasts multiple advantages. It not only efficiently meets pellet requirements, but also comes with a stable and simple structure. By choosing our equipment, you can expect a rapid return on investment.

Working Process Of hemp pellet mill

We have optimized the pelletizing process for this equipment. The innovative dual-roll system works in tandem with alloy ring die. Combined with an 80°C high-temperature environment, it produces superior hemp pellets.

- Feeding: Powdered hemp hay enter the pelletizer via an arch-breaking feeder.

- Conditioning: The raw materials undergo high-temperature gelatinization in the conditioner to enhance their binding properties.

- Extrusion: The dual pressure rollers exert intense pressure, forcing it into the apertures of ring die.

- Forming: The cylindrical material is discharged continuously from the apertures.

- Cutting: A dual-blade mechanism slices them into uniformly sized pellets.

The above outlines the fundamental pelletizing process for this hemp pellet machine. We will adjust the number of conditioners and ring die parameters according to your production requirements.

Freshly produced hemp pellets are usually moist and soft. Therefore, direct packaging may result in pellet loss. We offer highly efficient, energy-saving cooling equipment and automatic packaging scales. If you are interested in our equipment, please provide us with your detailed production requirements.

Applications of hemp Pellet Machine

This pelletizer has gained widespread adoption because of its high capacity for producing pellets. It is ideal for large-scale production of biomass pellets, ruminant animal feed and bedding materials.

Processable Raw Materials

The design of the hemp stalk pelletizer is based on the processing requirements for high-fiber materials. For this reason, it is equally well-suited to producing other fibrous biomass materials.

Hemp

Alfalfa

Clover

Ryegrass

Oat Grass

Timothy grass

The Perfect Pellets

As a powerful grass pellet machine, it can also process various high-fiber materials into pellets. Each material results in pellets with an ideal structure and high formation rate.

As well as producing standard hemp pellets, you can blend straw or grains in at the correct ratios for pelletization. This enables the production of premium animal feed.

Below are examples of pellet products. These pellets have a compact, full and smooth structure. Contact us now to discuss your production needs.

hemp Pellets

Clover Pellets

alfalfa Pellets

Ryegrass Pellets

Oat Grass Pellets

Timothy Grass Pellets

Elephant grass Pellets

hay Pellets

Global CASES

With our high-quality equipment and services, we have earned high praise from customers worldwide. Whether you require a single hemp pellet machine or a complete production line solution, our products consistently deliver exceptional performance.

Hemp Feed Pellet Project in the United States

We provide a solution for producing feed pellets for ruminants with a diameter of 6 mm. The project has a production capacity of 8–10 T/H. The primary raw materials used are grains, hemp and alfalfa.

Hemp Feed Pellet Machine for Sale in the Netherlands

Our client is a feed manufacturer. They require high-capacity equipment for producing feed pellets. The raw materials used are corn, grass and hemp. Our solution has delivered excellent results for them.

Canada Hemp Pellet Production Project

These materials include hemp stalks, seeds and straw. The aim is to produce high-quality hemp pellets for sale. We have supplied a high-capacity hemp pellet mill with a production rate of 2.8–3.0 T/H.

hemp pellet press machine for Sale in Poland

Our client has plenty of hemp and forage. They intend to mix these with grains to produce ruminant feed. We offer pellet mill with a capacity of 1–2 T/H, as well as other production equipment.

Australia Hemp Seed Pellet production Project

The client required a solution for blending hemp seeds with grains to produce animal feed. The pellet mill, equipped with a robust pelleting system, successfully produced high-quality feed pellets in various ratios.

South Africa Biomass hemp Pellet Project

The client runs a biomass pellet plant. Its raw materials include hemp and rice straw. We provide a production line with a capacity of 3–4 T/H, which can produce clean fuel with a high calorific value.

Why Choose RICHI?

We offer industry-leading hemp pellet machine for sale.

RICHI Machinery was established in 1995, and we have remained dedicated to providing customers with the best pellet solutions. We are driven by customer satisfaction and are engaged in the research of pellet machinery. To date, we have successfully supplied high-quality hemp pelletizer machines to clients worldwide.

Drawing upon extensive customer service experience, we have a thorough understanding of your production needs and the challenges at every manufacturing stage. Consequently, we offer an integrated solution combining pre-sales and after-sales support to protect your hemp pellet production operations.

Our after-sales service includes a one-year warranty and a prompt response to any quality issues. To ensure rapid dispatch of components, we also maintain a global network of spare parts. If you encounter any production challenges, we will provide solutions to help you resume operations swiftly. We also offer the following services:

Free consultation Service

At RICHI, our experienced engineers and sales team offer free consultations on hemp pellet making machines. We understand your production requirements and queries, so feel free to ask us any questions you have about the production solutions.

Customised Equipment Service

Should you have specific requirement for output and standard for pellets, we can provide tailored solutions to meet your needs. Our specialist technical team and large-scale manufacturing facilities can accommodate all your equipment needs.

Turnkey Production Solutions

Besides exceptional hemp pelletizer for sale, our production line solutions have earned the trust and support of clients. Our turnkey solutions, in particular, offer complete service including project planning, construction, equipment installation and operator training.

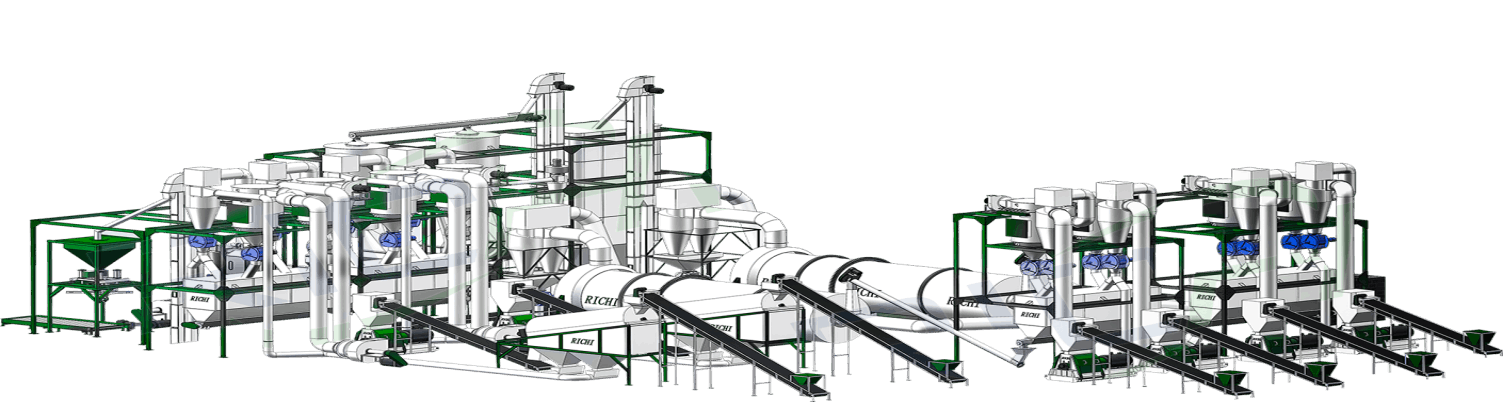

hemp Pellet Production Line

The hemp pellet machine is the key equipment in this production line. We also provide a complete production equipment solution. This industrial-grade grass pellet production line has a capacity ranging from 0.5 to 40 T/H. We also offer customized services and turnkey solutions.

01

Crushing

The hemp has a high fiber content, which can cause clogging of the equipment. Therefore, during pre-processing, the raw material must be crushed into a powder with a particle size of 3–5 mm. This section can also crush other high-fiber materials.

02

Drying

At this stage, we designed a high-capacity drying drum. This can dry large quantities of material to an ideal moisture level of 18%. We also incorporated safety monitoring devices such as audible and visual alarms and spark detectors.

03

Pelletizing

Our pellet mill is installed in this section. By installing different numbers of conditioners, it can produce pellet products for various applications. We also offer ring dies with different apertures to suit various types of pellet production.

04

Cooling

The freshly formed hemp pellets have a relatively moist and soft texture. Packing them at present would result in pellet loss. Therefore, we have designed a counterflow cooler to quickly stabilize the pellet structure.

05

Screening

This section is designed for screening commercial hemp pellets. We offer a range of pellet screening specifications to meet a variety of sales demands. The residual material from this process can be used for secondary pelletization.

06

Packaging

We also offer equipment with different automation levels for pellet packaging. If you operate on a large scale, or need standardized packaging, this is essential. Fully automatic packaging scales can reduce material and labor costs.

Application Scenarios

Our hemp pellet machine effectively prevents material build-up when processing complex mixed materials. This production line solution features scientifically divided processing stages, offering high efficiency and energy savings.

These features enable the production of high-quality hemp pellets, making them a popular choice for many biomass pellet plants and feed mills.

We offer free consultation on production solutions around the clock.

We provide a one-stop service for hemp pellet production projects.

hemp Pellet Plant

feed plant

Rapid Customisation Services

High Return on Investment

Other Related Production Equipment

RICHI operates large-scale manufacturing facilities for production machinery. As well as advanced hemp pellet machine for sale, we design and manufacture other high-efficiency production machinery. These devices also play critical roles in hemp pellet production line.

Forage Crusher

It can crush high-fiber grasses and straw into powder, with a final particle size of 0.5-20 mm. The screen mesh sizes can be customized.

Drum Dryer

With double-drum design and variable frequency speed control, it can adapt to various material moisture levels, achieving uniform and rapid drying.

Cooling Machine

This equipment is highly automated, minimizing pellet breakage. The temperature of the cooled pellets will not exceed room temperature by more than 3–5°C.

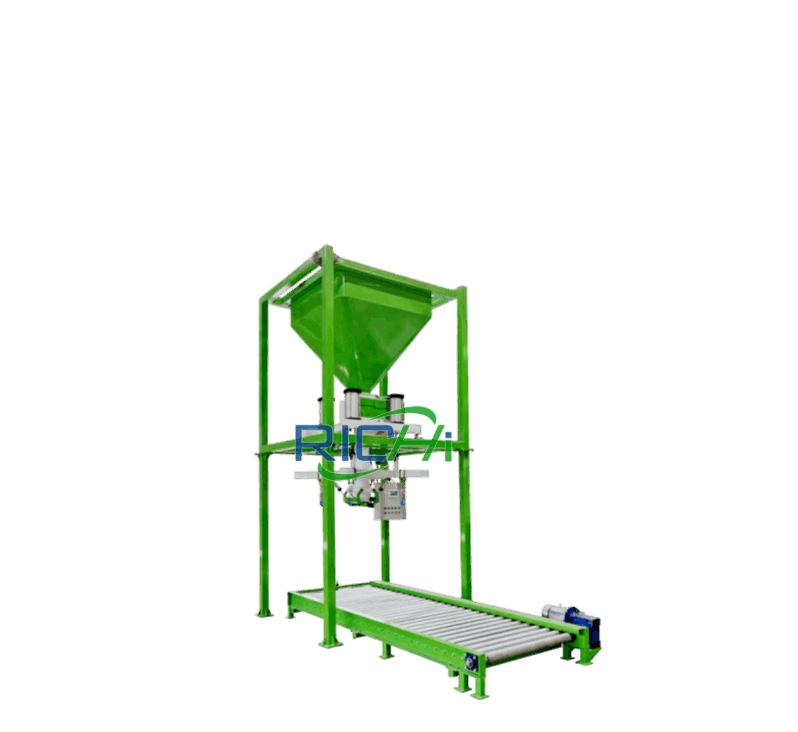

Packaging Scale

It provides fully automated weighing and uniform packaging. The sealing options include thermoplastic sealing, seam sealing, or mixed sealing.

Other pellet machines

We have also designed other innovative pellet machines. Like the hemp pellet machine, they offer energy-saving, eco-friendly and highly efficient performance. We are committed to providing you with premium pellet production in the long term.

alfalfa pellet machine

Our alfalfa pellet machine is ideal for meeting your high-standard feed requirements.

hay pellet machine

We offer efficient hay pellet machines that produce clean energy and high-protein feed effectively.

Miscanthus pellet machine

Our practical miscanthus pellet machines can produce premium livestock feed and fuel.

EFB Pellet Machine

It features a robust pelletizing system for processing empty fruit bunches into pellets.

rice husk pellet machine

This machine produces both highly calorific clean fuel and high-quality animal feed.

Frequently Asked Questions

Based on our global customer service experience, we understand the confusion you may face when selecting a hemp pellet machine. Below, you will find answers to frequently asked questions on equipment selection, raw material processing and after-sales service. If you have any other concerns, please feel free to consult us at any time.

–

What factors can affect the quality of hemp pellets?

The quality of hemp pellet is directly related to the raw materials. Specifically, it includes the moisture content and size of the raw materials. High-fiber hemp needs to be crushed into a powder within 3-5 mm, which is conducive to a uniform granular texture. And it can reduce the risk of equipment blockage and wear.

The second factor is the moisture content of the raw materials. The ideal granulation humidity is 15% to 18%. If the moisture content of your raw materials is high, it will reduce the adhesiveness. Low humidity can cause looseness and make it difficult to shape.

Our equipment features stable granulation capacity and a high forming rate. Under normal raw material processing conditions, it can continuously and stably produce high-quality hemp pellets.

–

Is this hemp pellet machine difficult to operate?

Our hemp pelletizer has a simple structural design and is easy to operate. We will provide the corresponding equipment user manual, maintenance guide and video tutorial. In this way, even personnel without production experience can quickly master the operation skills.

For the production line equipment, we will dispatch engineers to provide equipment installation and operation training. Ensure your production process and subsequent maintenance. (View YouTube)

–

What other biomass raw materials can a hemp pelletizer machine process?

The pellet mill we produce have excellent versatility. Its double-roller system can extrude low-density and high-fiber materials very well. Its innovative alloy ring die is harder and more wear-resistant. Therefore, it can not only handle grass such as cannabis and alfalfa, but also be used for straw pelletizing.

We can also provide other biomass pellet machines. For example, peanut shell pellet machine, wood chip pellet machine, corn stalk pellet machine, etc. They are all highly efficient industrial-grade equipment.

–

What maintenance is needed for a hemp pellet making machine?

The maintenance work of the biomass hemp pellet machine includes daily cleaning, adding lubricating grease, and regular inspection. Material residue is prone to cause equipment corrosion. Therefore, after the equipment is used, you need to clean up the residual materials in it in a timely manner.

If your pelletizer has been running continuously for a long time, you need to apply lubricating grease to key parts such as bearings. This can reduce the subsequent wear and tear of the equipment.

Regularly inspect the wear conditions of the ring die and the pressure roller. Component wear will lead to a decline in particle quality and output. Therefore, when the wear of the ring die reaches the critical line, it needs to be replaced in a timely manner. This can avoid causing production suspension losses as a result.

–

What are the after-sales services for hemp pellet machine?

We offer a 12-month warranty. Any quality issues will be resolved promptly and properly. For vulnerable parts such as ring dies and pressure rollers, we have established a global spare parts supply system. This system ensures the rapid delivery of spare parts.

We also offer long-term technical support. You can consult at any time about any technical issues in subsequent production. By choosing our production equipment, you will receive the most considerate after-sales service.