Hay Pellet Machine For Sale

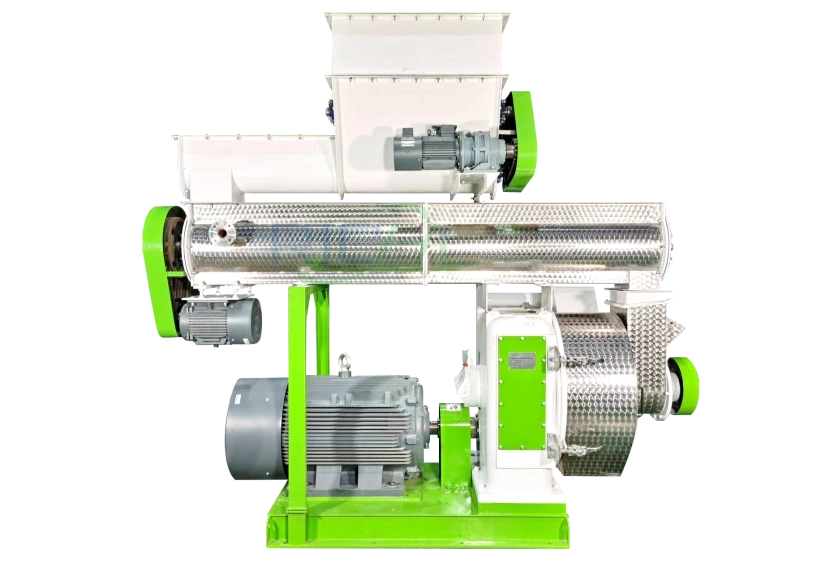

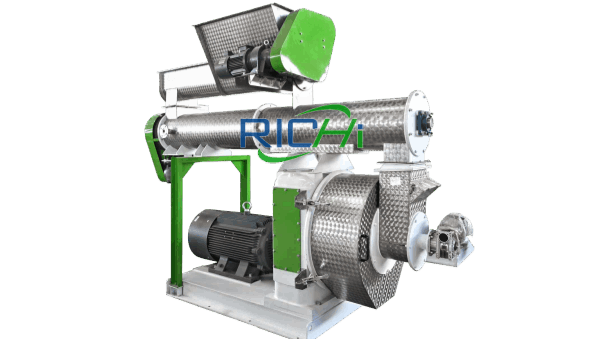

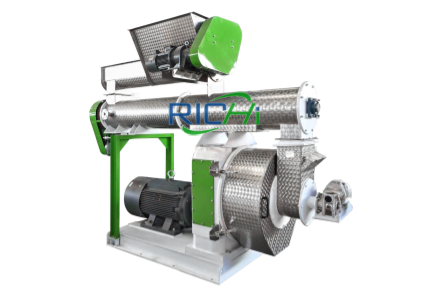

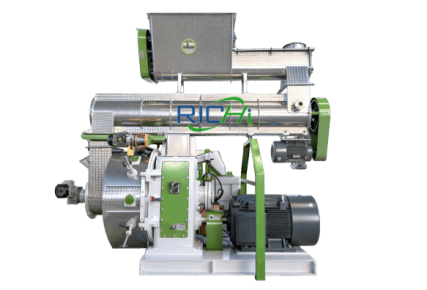

This hay pellet machine for sale can compress hay into plump, compact pellets, which helps to preserve the nutritional content. We offer various options for production capacity. Contact us to discuss your customised equipment solution.

Efficient hay Pellet Machine For Sale

As specialized manufacturer of pelletizing equipment, we offer high-efficiency hay pellet mills. Each machine is designed innovatively and undergoes rigorous technical testing. This ensures that it produces perfect hay pellets for your operation.

Hay is a herbaceous plant material that is rich in fibre, plant protein and other nutrients. Our hay pellet mill can process alfalfa, straw, bean stalks and other hay materials into pellets. The resulting feed pellets provide comprehensive nutrition and are more palatable than loose hay.

If you produce hay pellets for combustion, our machinery is equally effective. Based on an efficient pelleting system, it produces hay pellets with a compact structure and a higher calorific value. Whether you need hay for animal feed or as fuel, our hay pellet machines for sale provide efficient results.

Working Process Of hay Pellet mill

Thanks to its professional structural design, this hay pellet mill incorporates a scientifically pelletising system. It produces excellent hay pellets swiftly and easily.

We have high-capacity hay pellet machine for sale, which can meet your diverse production requirements.

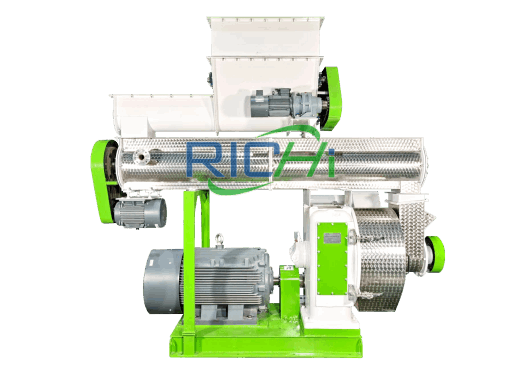

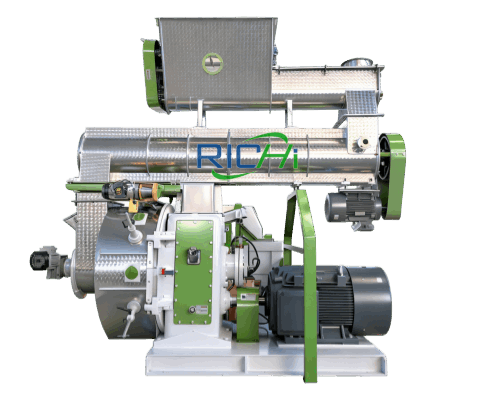

The high fibre content of hay affects the efficiency of pelletisation. Therefore, the raw material must be crushed before pelletisation. Clean hay powder is fed into the pellet mill through a wide inlet. A break-arch feeder is installed here to ensure a more consistent feed rate.

After processing through the high-temperature conditioner, the hay achieves optimal conditioning and binding properties. A forced feeder is installed at pelletising chamber inlet, which ensures the material enters roller system smoothly. The pelletised hay is then continuously extruded through the die under the powerful pressure of the twin rollers.

Finally, blades cut the pellets into uniform pieces. After cooling to ambient temperature, the hay pellets take on their final shape. We can adjust the die dimensions and compression ratio according to your specific production requirements.

Innovative Design

The RICHI hay pellet machine for sale features multiple innovative designs. Several anti-blockage devices and a scientifically advanced pelletising system have been incorporated. These designs enable it to produce perfect hay pellets efficiently.

Due to the light nature of hay dust, it tends to accumulate at the feed inlet. In response, our machine features a spiral arch-breaking mechanism and a forced feeder. This effectively resolves clogging issues while increasing the output.

The optimized conditioner improves the digestibility and absorption rate of hay feed. Meanwhile, the multiple ring die aperture sizes can accommodate different pellet size requirements. We also offer customized hay pellet mills to meet your diverse output and quality needs.

01

Feed Inlet

This section has a wider design, with an internal anti-bridging device to ensure that large volumes of grass powder can enter the conditioner smoothly.

02

conditioner

This unit has a wider and longer design to uniformly condition large quantities of dry hay. It features a heat-resistant, food-grade stainless steel construction.

03

Forced Feeder

Unconditioned hay powder tends to gather at the inlet of the pellet chamber. Therefore, this device pushes the material inwards to ensure smoother pelletisation.

04

Ring Die Mold

This component is made of the alloy material 42CrMo to enhance its wear resistance. The arrangement of holes has been designed to increase output per unit.

05

Dual-Roll System

The dual-roller design provides improved compression performance. The rollers have a wider working area and are better suited to processing lightweight hay.

06

Ventilation Outlet

It can vent the high-temperature water vapour generated during granulation, thereby protecting the granulation environment without losing material.

Parameters of hay Pellet Machine For Sale

| Model | CZLH320 | CZLH350 | CZLH420 | CZLH520 | CZLH678 | CZLH768 |

| Main Motor Power(kw) | 22 | 37 | 90 | 132 | 185 | 250 |

| Breaker Feeder Power(kw) | 2.2 | 2.2 | 3 | 3 | 3 | 4 |

| Forced Feeder Power(kw) | 0.75 | 0.75 | 1.5 | 1.5 | 1.5 | 1.5 |

| Ring Die Inner Diameter(mm) | 320 | 350 | 420 | 520 | 673 | 762 |

| Pellet Diameter(mm) | 4-12 | |||||

| Capacity(T/H) | 0.5-0.6 | 1.0-1.2 | 1.8-2.0 | 2.8-3.0 | 4-5 | 6-8 |

The above details the standard production capacity of this hay pellet making machine. All models deliver the same high-quality production experience. If you require additional specifications or customized solutions, please feel free to contact us.

Advantages of hay Pellet mill

Traditional pelletizers often struggle with low forming rates, high energy consumption and susceptibility to wear. However, our hay pellet mill can overcome these challenges, offering premium hay pellet production with unique advantages.

Applications of hay Pellet mill

We offer versatile hay pellet machine for sale. It can produce hay pellets for a variety of applications. We also provide customised equipment solutions tailored to your specific needs.

Processable Raw Materials

Our upgraded hay pellet making machine offers enhanced performance when processing lightweight forage materials. As such, it can also produce pellets from other types of grass and straw.

Pasture Hay

Cattail hay

Alfalfa hay

Rye hay

Oat hay

sudan hay

The Perfect Pellets

This hay pellet making machine can process various types of grass and straw. It has a robust pelletizing mechanism that compresses these materials into uniform, dense and well-formed pellets.

Alongside single-ingredient pelleting, it is also possible to produce hay pellets with mixed ratios. For example, adding grains, soybean meal and straw optimizes the nutritional profile of the pellets. This machine can efficiently pelletize various ingredient ratios.

Below are examples of pellets produced using this hay pelletizer. With our grass pellet machine, you can also produce such high-quality pellets.

Alfalfa Hay Pellets

Oat hay Pellets

Cattail Hay Pellets

Sudan hay Pellets

Rye hay Pellets

Reed hay Pellets

sheepgrass Pellets

pampas hay pellets

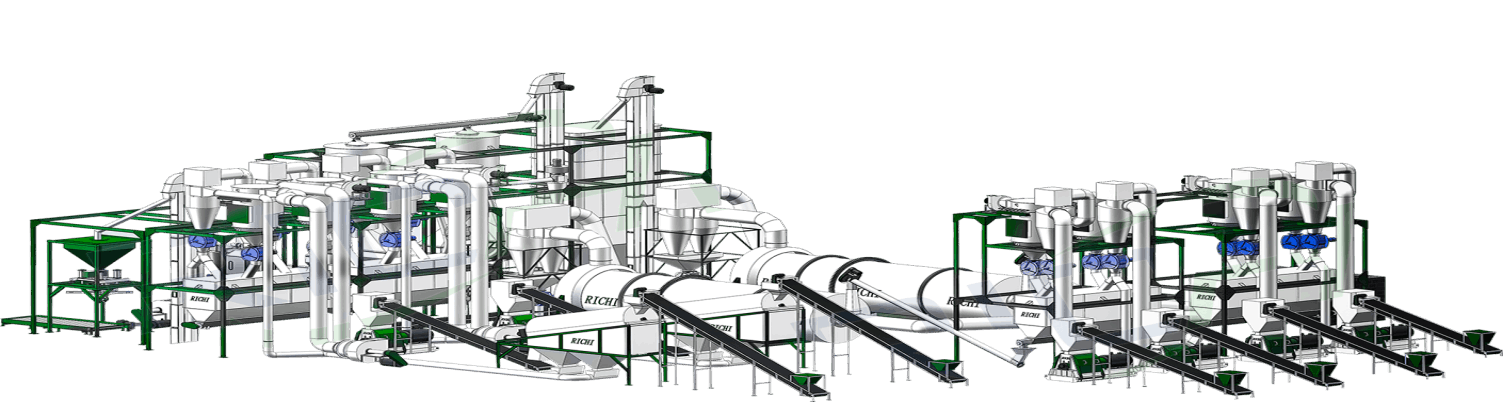

hay Pellet Production Line

We not only offer professional hay pellet machine for sale, but also provide complete production line solutions. All stages of the production process are scientifically organized, with robust main machinery and auxiliary systems in place. We also deliver turnkey solutions for any grass pellet production line.

01

Crushing

Hay materials contain abundant fiber, which can affect the formation rates of pellets when processed directly. Therefore, we have designed this process stage, in which a powerful forage shredder can easily pulverise the hay into a powdery consistency of 3–5 mm.

02

Drying

The moisture content of raw materials has a significant impact on pellet formation. For this reason, this process stage involves a large-capacity drying drum, which dries grass powder to an ideal moisture level of 15–18%. We also offer other drying equipment.

03

Pelletizing

The hay pellet making machine plays a crucial role in this process. We can adjust the number of conditioners according to your production requirements. With an optimised dual-roller system and die, it quickly transforms hay into perfectly sized pellets.

04

Cooling

The cooling section quickly cools hay pellets to ambient temperatures, ensuring their stable structure. We offer cooling equipment featuring various materials and configurations. Counterflow cooler is the most commonly option.

05

Screening

This efficient screening process ensures that the hay pellets are uniform in size and meet sales standards. At the same time, it separates other materials for secondary pelletisation. This improves material utilisation and prevents waste.

06

Packaging

This section features a range of specialised packaging equipment, which offers different levels of automation. The fully automatic packaging scales can weigh and package materials automatically, ensuring consistent specifications while reducing labour costs.

Application Scenarios

Our hay pellet machine for sale can produce uniform, plump hay pellets. By maximising the nutritional content of the pellets, they can deliver superior feeding results. Therefore, it is ideal for use in producing feed on various livestock farms.

Additionally, this equipment offer different capacity models to suit production lines from 0.5 to 100 T/H. It can pelletise raw materials in various proportions to produce perfect pellets. Therefore, it is popular among many hay pellet manufacturers.

We offer free consultations on production solutions and equipment around the clock.

We provide a one-stop service for hay pellet production projects.

hay Pellet making Plant

Livestock Farms

Rapid Customisation Services

High Return on Investment

Global Projects

RICHI has extensive experience in manufacturing pellet equipment. We have provided superior services to over 150 countries and regions worldwide. Whether a single hay pellet making machine or complete production line solutions, they consistently deliver excellent performance.

Hay Pellet mill for Sale In South Africa

The customer selected our hay pelletizer with production capacity of 3–4 T/H. It processes large quantities of hay and straw into high-quality feed pellets, which are then sold to local livestock farms.

Hay Pellet making plant In Uzbekistan

The raw materials are alfalfa powder and grains. With a target production capacity of 1-2 T/H, it is classified as a small-scale production line. Our hay pellet press is perfectly suit to the task.

Argentine Hay Pellet Production Project

To meet this customer’s requirements for ruminant feed, we adjusted the ring die aperture. This hay pellet maker can process alfalfa hay into 6 mm hay feed at capacity of 3 T/H.

Hay Pellet Machine for Sale In Thailand

Our client has many hay bales, which consist mainly of timothy grass and alfalfa. We provided an efficient hay pelletizer, a crusher and other equipment, achieving remarkable production results.

Afghanistan Hay Pellet Manufacturing Plant

This project involves a high-capacity production line with a capacity of 10 T/H. The raw materials are alfalfa hay, corn and cottonseed meal. The finished pellets for sale are used for poultry feeding.

Hay Pellet Machine for Sale In USA

For this project, alfalfa, hemp hay and straw are used as raw materials. The customer, a large local dairy farm, selected a large hay pelletizer for a 11-12 T/H hay pellet production line.

Canadian Hay Pellet Production Project

Through supplying a 2 T/H hay pellet making machine, we helped our client achieve an excellent return on investment. This hay pellet press can produce hay compound feed for pigs and cattle.

Hay Pellet mill for Sale In Turkey

Efficient pelletising of mixed raw materials is this equipment’s key function. By producing 8 mm high-protein hay pellets, it offers a significant economic return to this customer.

Why Choose RICHI?

We offer industry-leading hay pellet machine for sale.

RICHI Machinery was established in 1995, and we have remained dedicated to providing customers with the best pellet solutions. Our commitment to customer satisfaction drives us to research pellet machinery. To date, we have successfully supplied high-quality hay pellet maker to clients worldwide.

Drawing upon extensive customer service experience, we have a thorough understanding of your production needs and the challenges at every manufacturing stage. Consequently, we offer an integrated solution combining pre-sales and after-sales support to protect your hay pellet production operations.

Our after-sales service includes a one-year warranty and a prompt response to any quality issues. To ensure rapid dispatch of components, we also maintain a global network of spare parts. If you encounter any production challenges, we will provide solutions to help you resume operations swiftly. We also offer the following services:

Free consultation Service

At RICHI, our experienced engineers and sales team offer free consultations on the hay pellet mill. We understand your production requirements and queries, so feel free to ask us any questions you have about the production solutions.

Customised Equipment Service

Should you have specific requirement for output and standard for pellets, we can provide tailored solutions to meet your needs. Our specialist technical team and large-scale manufacturing facilities can accommodate all your equipment needs.

Turnkey Production Solutions

Besides exceptional hay pellet making machine, our production line solutions have earned the trust and support of clients. The turnkey solutions, in particular, offer complete service including project planning, construction, equipment installation and operator training.

Other Related Production Equipment

Besides advanced hay pellet machine for sale, we also provide other equipment and auxiliary systems required for hay pellet production line. With a team of professional engineers and large-scale manufacturing facilities, RICHI can meet all your customized requirements.

Raw Material Crusher

It can grind hay and straw into a powder with a particle size of 3–5 mm, which facilitates pelletisation.

Drum Dryer

It features a large capacity and a dual-barrel design for efficient, uniform drying of materials.

Cooling Machine

It rapidly cools high-temperature hay pellets to room temperature through counter-current cooling.

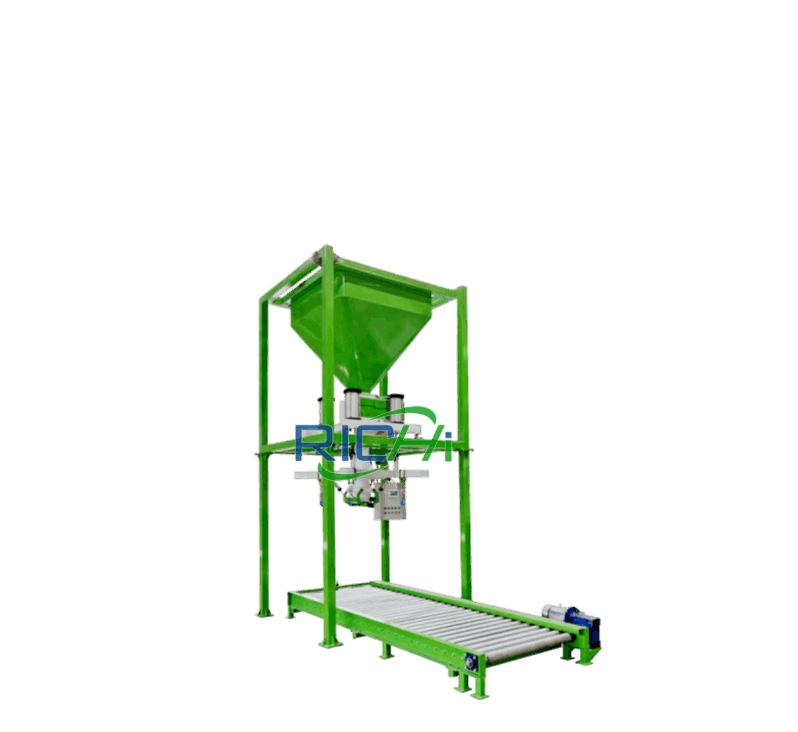

Packaging Scale

It provides fully automated weighing and uniform packaging. Packaging options include heat-sealed bags and conventional sacks.

Other pellet machines

We have also designed other innovative pellet machines. Like the hay pellet machine for sale, they offer energy-saving, eco-friendly and highly efficient performance. We are committed to providing you with premium pellet production in the long term.

alfalfa pellet machine

Our alfalfa pellet machine is ideal for meeting your high-standard feed requirements.

hemp pellet machine

We offer efficient hemp pellet machines that produce high-protein feed effectively.

Miscanthus pellet machine

Our practical miscanthus pellet machines can produce premium livestock feed and fuel.

EFB Pellet Machine

It features a robust pelletising system for processing hard-shelled materials into pellets.

rice husk pellet machine

This machine produces both highly calorific clean fuel and high-quality animal feed.

Frequently Asked Questions

Based on years of customer feedback, we understand the concerns that you have before purchasing equipment. Therefore, we have prepared some frequently asked questions and answers about this hay pellet machine for sale. If you have any other questions, please feel free to ask us at any time.

–

What are the raw material requirements of this hay pellet machine for sale?

Before pelletising, it is necessary to check the size and moisture content of the raw material. This is a fundamental requirement for hay pelletisation.

Firstly, the high fibre content of hay materials can present challenges during the pelletising process. The ideal raw material size is 3–5 mm, or even finer grass powder. This size is ideal for producing uniform, compact hay pellets.

Furthermore, the ideal moisture content of raw material is between 15% and 18%. Excessively high or low moisture levels will affect pellet formation. We also offer high-efficiency drying equipment to address this issue.

–

What are the benefits offered by this hay pellet mill?

Our machine is a modern, industrial-grade pelletiser. Its efficient granulation system compresses materials to save storage space. It also facilitates transportation and reduces losses.

Thanks to high-temperature compression, the hay pellets formed deliver superior feeding results. They prevent selective eating in animals and increase feed intake rates.

Furthermore, it transforms low-value hay and straw into high-quality commercial feed. This promotes resource recycling while generating significant economic benefits.

–

Does our hay pellet making machine require any particular operating skills?

This user-friendly pelletizer is easy to operate. Our design focuses on customers’ actual usage experience. Consequently, it is not only easy to operate, but also simple to maintain, including replacing parts and performing routine cleaning.

Although the machine is easy to operate, it is still essential to ensure standardized operating procedures. Following the correct usage process can extend the service life of the hay pelletizer. We recommend referring to the instruction manual for operating and performing daily maintenance. (View YouTube)

–

What daily maintenance is required for this hay pellet mill?

The daily maintenance of the hay pelletizer primarily involves three tasks: internal cleaning, lubrication of the rollers and bearings, and inspection of component wear. These tasks must be carried out after the equipment has been shut down and powered off.

After each operation cycle, it is important to promptly clean residual material from the interior. This will prevent compromising the quality of subsequent pelletisation and avoid component wear.

Following extended periods of continuous high-intensity operation, the pelletizer requires grease lubrication. This extends the service life of the roller system and bearings while minimising subsequent wear.

Finally, regularly inspect components prone to wear, such as rollers and ring dies. Our rollers and ring dies utilise wear-resistant alloy materials to extend their service life and reduce wear. You should replace ring dies promptly when wear reaches critical levels or when pellet output significantly decreases.

–

What after-sales services are included with the hay pellet machine for sale?

Each machine comes with a one-year warranty. We provide comprehensive solutions for any quality issues. The machine is shipped with a user manual and video tutorials. We also offer a global spare parts network, ensuring the rapid delivery of components.

If you have any technical questions during production, please feel free to consult us at any time. We provide long-term technical guidance.