Grass Pellet Plant

in USA

Pellet Diameter:

6-8mm

Raw Materials:

Primarily alfalfa and hemp, supplemented with a proportion of wheat straw

Application:

Production of grass feed pellets for ruminant

Project Name:

Fully Automated Grass Pellet Plant In USA (Turnkey Project)

Output:

11-12 T/H

USA Grass Pellet Market

The United States has an advanced agricultural and livestock industry. It has a vast market for grass pellet and abundant raw material supplies. With the continued expansion of the international market for grass pellets, the government has introduced tariff subsidy policies. Taken together, these factors suggest that the market for grass pellets in the United States holds tremendous growth potential.

However, no matter how rapidly the grass pellet market grows

High-quality grass pellets remain in constant short supply. Although grass pellets are an ideal feed for ruminants, they face challenges such as low formation rates, loose structure and unstable output. In practical use, problems such as nutritional imbalance and susceptibility to spoilage frequently occur.

Therefore, it is particularly important to have a production line capable of meeting the market’s demand for high-quality grass pellets.

Using our grass pellet production line ensures a stable pellet structure and maximizes nutrient retention. The grass pellet machine improves the palatability and digestibility of grass pellet by enhancing the gelatinisation of raw materials through a high-temperature conditioner. This delivers higher returns for this grass pellet plant in USA.

CLIENT PROJECT DETAILS

Our client is a grass pellet plant in USA, and primarily producing feed pellets for sale. Due to high demand, they sought a low-cost, high-capacity grass pellet production system. The existing production line equipment was unable to meet the daily production requirements. Following extensive consultations and on-site factory inspections, the client selected RICHI as their project supplier.

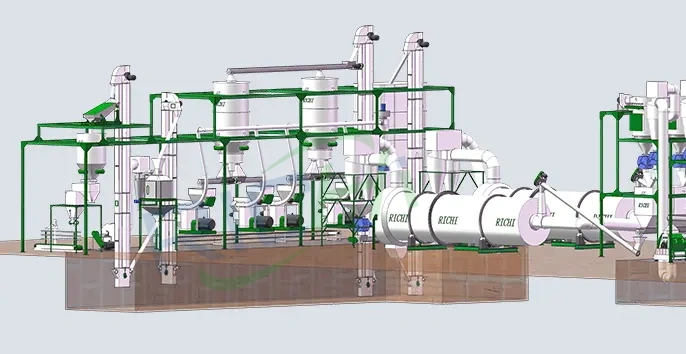

The customer’s previous equipment frequently experienced blockages, wear, and low pellet formation rates, severely impacting output. They required high-intensity pelletizing equipment capable of processing mixed raw materials. Our grass pellet production line effectively resolved this challenge. The grass pellet plant USA has a limited space. Our turnkey solution effectively resolves site planning through 3D modeling and other methods, achieving an optimal layout.

Customers required the blending of fresh grasses with straw for pelletization. Our high-efficiency drying equipment is designed to effectively address these challenges.

Every machine is designed for user-friendly operation. The production line is accompanied by on-site installation and comprehensive training by engineers.

CUSTOM-TAILORED SOLUTIONS

The project of grass pellet plant in USA encountered several practical challenges in the initial stages, including client facility constraints, raw material ratios and pellet storage. Drawing on our extensive project experience, we successfully helped the client to achieve their desired outcomes for alfalfa pellet production.

The following are also common issues encountered in most grass pellet production lines.

The uneven ground surface makes it difficult to operate the equipment stably. The height restriction cannot ensure the structure integrity of large-scale production lines. Drawing on years of project experience, our engineering team rebuilt the grass pellet factory USA to ensure production line functionality.

The ratio of different grass pellets in the formulation has a significant impact on the uniformity and structural stability of the resulting pellets. We have equipped the production line with robust raw material processing equipment, including forage grinder, mixer, and drying drum. This solves the issue of raw material low formation rate.

Excessive raw material moisture often compromises grass pellets structural stability. Insufficient moisture reduces pellet formation efficiency. Our high-efficiency drying system can handle raw materials with a wide range of moisture levels. Its twin-drum design ensures the optimal moisture content for pelletization.

Many workers have trouble operating specialized pelleting equipment. Achieving smooth and stable grass pellet production is difficult. Our turnkey solution includes complimentary operational training. With the help of our engineers, the workers at this grass pellet plant in USA successfully mastered production line operations.

The Production Process of grass pellet plant in uSA:

To meet the high-volume production requirements of grass pellet factory USA, we have installed high-capacity grass pellet machines on the production line, with multiple units operating in parallel. They can preserve the nutritional structure of grass pellets and enhance palatability. Due to the high moisture content of the alfalfa hay material, we have installed an efficient drying system and pellet coolers to ensure the pellets have the optimal structure.

01

Crushing

In order to meet high-output demands, we use two grinders to process high-fiber raw materials and produce particles measuring 3–5 mm.

02

Mixing

Our large-capacity mixer, handling 4m³ per batch, features dual-shaft paddles to effortlessly achieve uniform blending of diverse materials such as alfalfa, hemp, and straw.

03

Drying

Fresh grass with high moisture content is subsequently dried in a drum dryer, reducing moisture to the ideal range of 15%-18%.

04

Pelletizing

The grass pellet machines, with a capacity of 2.8-3.0 T/H, produces perfectly formed grass pellets. A large-capacity 40m³ storage bin ensures smoother transition between mixing and pelletizing.

05

Cooling

A large-capacity counterflow cooler rapidly cools pellets, further preserving their optimal structure. A high-frequency vibrating screen precisely and rapidly separates finished pellets, ensuring pellet quality.

06

Packaging

A fully automatic packaging scale automatically weighs and packages products, ensuring consistent packaging specifications and saving labor costs.

the CONFIGURATION of Grass Pellet PLANT in USA

The customer’s production requirements include a high level of automation, high output and high quality. We offer a production line comprising multiple high-capacity, high-efficiency grass pellet machines operating in parallel. It also features a robust raw material drying system, as well as pellet cooling, screening, and packaging and equipment.

01

Crushing System

The project’s raw materials include a mixture of straw and alfalfa, both of which are high-fibre feedstocks. For this reason, we installed a dedicated forage crusher to speed up the process. Its larger capacity ensures effective crushing while increasing the output.

02

Mixing System

This production line is equipped with a large-capacity mixer to ensure the effective granulation of mixed raw materials. Its enlarged chamber design can accommodate greater volumes of material for thorough blending. The internal dual-shaft paddle design guarantees a more uniform mix.

03

Drying System

The high moisture content of alfalfa directly impacts pelletising efficiency. Therefore, this project incorporates two large-capacity drying drums. With a dual-barrel design featuring inner and outer cylinders, they deliver superior drying results. Both units operate simultaneously to enable the rapid drying of large volumes of raw material.

04

Pelletizing System

In order to meet the high-volume production demands of this grass pellet manufacturing plant USA, we have installed four 130 KW high-power alfalfa pellet machines. These machines feature a dual-roller design to ensure the pellets meet precise specifications. The resulting grass pellets have a uniform texture and enhanced structural stability.

05

Cooling And Screening System

The system consists of integrated counterflow coolers and vibrating screens for coordinated operation. This ensures smoother transitions between cooling and screening. Combining both units saves space while increasing the speed of grass pellets production.

06

Packaging System

The packaging section is equipped with a fully automated ton-bag scale. This device weighs granular materials automatically and fills bags rapidly. The customer opted for heat-sealed packaging, which ensures consistent packaging standards and significantly reduces labour costs.

This project of grass pellet plant in USA began in 2024 with the start of investment and construction. Since its completion, the production of the plant has been of an excellent standard, and we have always enjoyed a good relationship with our clients.

For this project of grass pellet plant USA, we provided our client with comprehensive end-to-end services, including pre-sales consultation, exclusive customization, post-sales follow-up and ongoing support. As an equipment manufacturer with over three decades of industry experience, we operate large-scale manufacturing facilities capable of delivering solutions tailored to all your grass pellet production needs.

We are committed to delivering the highest quality service experience through our dual-track online and offline service channels.

RICHI Production Solutions

Through years of customer service, RICHI Machinery has developed a comprehensive service system. This includes end-to-end solutions from equipment consultation and project planning to construction, worker training, spare parts supply, and equipment upgrades. Besides this project of grass pellet plant in USA, you can also confidently choose our other grass pellet production solutions.

Production Line Solution

We provide professional grass pellet machines that can solve the problems of low formation rates and unstable output. Our high-efficiency production line solutions can meet all production needs of grass pellet plants, with capacities ranging from 0.5 to 100 T/H. Choose the turnkey production line solutions, and you will achieve maximum return on investment in the shortest time.

Customized for Clients

At RICHI, we provide customized design solutions for grass pellet production equipment and production lines, tailored to your specific requirements. Our customization services include equipment customization, project planning, engineering construction and dedicated technical support. Of course, comprehensive after-sales service is also included.

One-Stop Service

All equipment and production line systems supplied by us come with a one-year warranty. We respond promptly to any product quality issues. We also provide long-term technical guidance and welcome production-related technical questions at any time. You will also gain access to our global network spare parts supply system.

Professional Manufacturer

RICHI is an experienced manufacturer of particle processing machinery. Every machine we deliver is meticulously designed and rigorously tested. Thanks to our specialized equipment and premium services, we have completed over 2,000 projects worldwide. Partner with us to effortlessly maximize your investment returns.

GRASS PELLET PROCESSING SOLUTIONS

Our grass pellet solutions include specialized pellet machines and production line systems. These systems enable the efficient grass pellet production of large, medium, and small-scale grass pellet plants, farms, breeding facilities, etc. This project of grass pellet plant in USA is a turnkey solution. We also offer customized services for other solutions. (View YouTube)

Grass Pellet Production Line

The production line is suitable for manufacturing various grass pellets, including alfalfa, hemp, hay, hops, etc.

Alfalfa Pellet Production Line

It can efficiently process alfalfa raw materials to produce more palatable grass feed pellet.

Reed Grass Pellet Production Line

It can process reed grass into perfect animal feed, and meet the requirements for high-calorie fuel pellets.

Hemp Pellet Production Line

It can grind the high fiber content of hemp into pellets with a uniform texture and compact structure.

Oat Grass Pellet Production Line

It can process oat straw herb, dried oat grass, oat grass powder into uniquely flavored oat grass pellets.