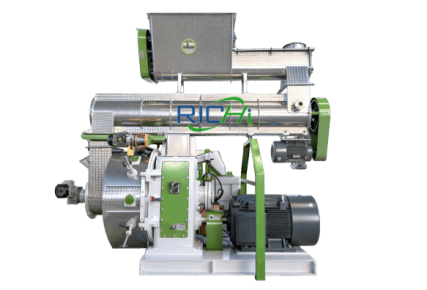

Corn Stalk Pellet Machine

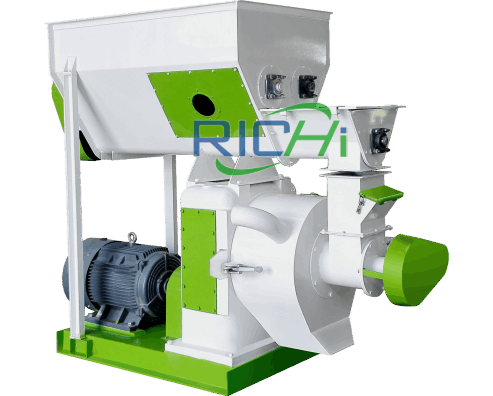

The corn stalk pellet machine is advanced industrial-grade production equipment. It efficiently produces corn stalk pellets, which are suitable for use as high-calorific-value fuels, animal bedding, and more. We also provide customized corn stalk pelletizer to meet your diverse needs.

Efficient Corn Stalk Pellet Machine For Sale

We are an experienced equipment supplier. Therefore, we can provide genuinely efficient corn straw pellet machine. Each machine boasts high-efficiency pelletizing capability and energy-saving advantage to support your efficient production.

Corn stalks make excellent fuel. When processed through our pelletizer, their combustion value is maximized. These pellets can achieve a calorific value of 4,500–5,000 kcal/kg, offering enhanced durability. They are more convenient for transportation and storage.

Our equipment is energy efficient and complies with multiple international environmental standards. Its optimized molds can produce pellets of various sizes. Standard biomass pellets measure 6 mm, 8 mm or 10 mm in diameter. Our machinery can produce multi-size pellets ranging from 4 mm to 12 mm in diameter.

Innovative Design

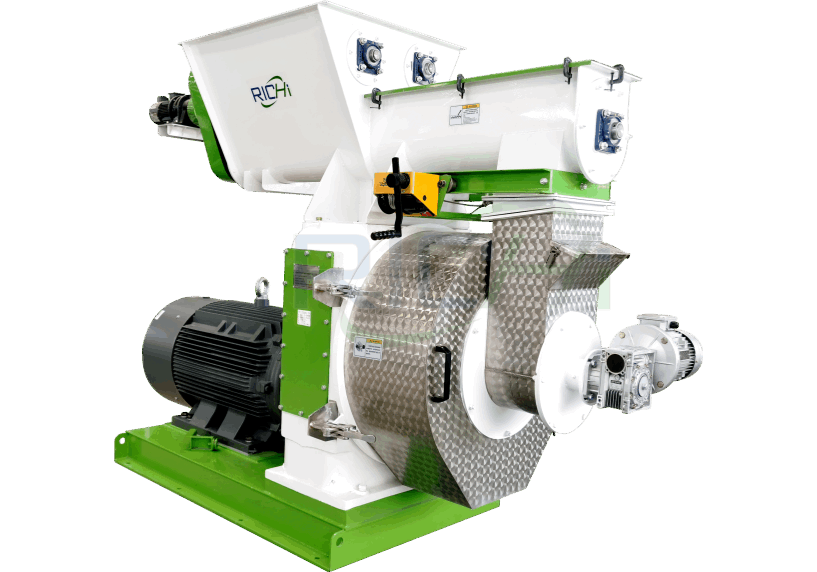

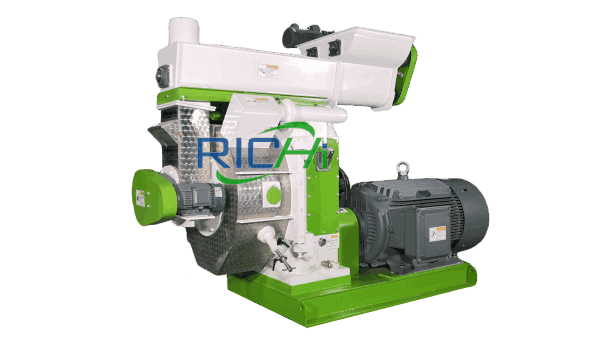

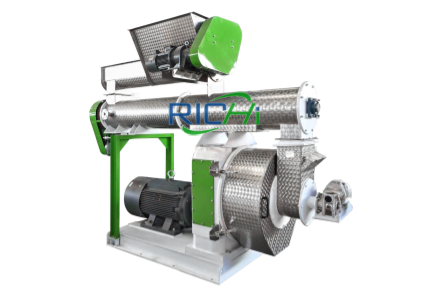

RICHI corn stalk pellet machine incorporates multiple innovative designs, including anti-bridging features and an advanced pelletizing system. We are committed to manufacturing innovative pellet mills to enable your efficient production.

Due to the lightweight nature of corn stalks, they are prone to clogging. Therefore, this equipment incorporates multiple anti-clogging devices, such as arch-breaking feeder and forced feeding system. These enhance pelletizing efficiency and increase output per unit.

The machine features an optimized roller system and an innovative ring die. These components substantially increase pellet formation rates. Ring dies with different aperture sizes enable the production of differently sized pellets. We also offer bespoke corn stalk pelletizer.

01

Arch-breaking feeder

This device is installed at the feed inlet. Its reverse-rotating paddles ensure straw powder enters smoothly.

02

Forced Feeder

It can push accumulated material into the granulation chamber, thereby accelerating the pelletizing process.

03

Multiple Motor Groups

We have installed motors at critical points. This ensures the entire machine operates with enhanced stability and efficiency.

04

Ring Die Mold

The ring die is made from 42 CrMo alloy, ensuring optimal compression ratios and enhanced wear resistance.

05

Dual-Roll System

This innovative dual-pressure roller system can significantly increase the formation rate and length of pellets.

06

Exhaust Vent

The vent enables high-temperature steam to escape from the interior quickly, while keeping material inside.

Working Process Of corn stalk pelletizer

This pelletizer features several innovative structural designs. For this reason, it produces highly standardized products. We can adjust the parameters and molds according to your needs. Please feel free to ask us at any time.

We have high-capacity corn stalk pellet machine for sale, which can meet your diverse production requirements.

Dry corn stalk powder tends to clump together, which adversely affects pelletization efficiency. We have designed an arch-breaking feeder. As the powder passes through the device, it flows smoothly into the pelletizer. Here, the high-temperature steam and continuous agitation enhance its binding properties.

Then, a dual-roller system compresses the material into the die. This powerful extrusion process forces the material continuously through the apertures of ring die. Specially designed blades then cut the extruded material into uniformly sized straw pellets. The pellets are then discharged beneath the vertical pelletizing chamber.

After cooling to room temperature, the corn stalk pellets will achieve their optimal structural stability. This makes them easier to bale and store. Our energy-efficient pellet machine produces harder pellets that helps you to avoid losses and reduce costs.

Parameters of corn stalk Pellet Machine

| Model | MZLH 320 | MZLH 350 | MZLH 420 | MZLH 520 | MZLH 678 | MZLH 768 |

| Main Motor Power(kw) | 22 | 37 | 90 | 132 | 185 | 250 |

| Breaker Feeder Power(kw) | 2.2 | 2.2 | 3 | 3 | 3 | 4 |

| Forced Feeder Power(kw) | 0.75 | 0.75 | 1.5 | 1.5 | 1.5 | 1.5 |

| Ring Die Inner Diameter(mm) | 320 | 350 | 420 | 520 | 673 | 762 |

| Pellet Diameter(mm) | 4-12 | |||||

| Capacity(T/H) | 0.5-0.6 | 1.0-1.2 | 1.8-2.0 | 2.8-3.0 | 4-5 | 6-8 |

The above details the specific models and production capacities of this series of pellet mills. Each machine has been meticulously designed to deliver sustainable fuel production. If you require any additional specifications, please do not hesitate to contact us.

Advantages of corn stalk Pellet machine

Our machine is more energy-efficient and productive than other pelletizers. Its robust construction significantly extends its service life. Using our pelletizer will make your pellet production more efficient.

Applications of corn stalk Pellet machine

Our pellet mill boasts multiple applications. It not only produces high-quality corn stalk pellets, but can also process other types of straw pellets.

Processable straw Materials

This equipment is suitable for pelletizing various straw and hay materials. It can be used to pelletize single ingredients or mixed ratios, consistently achieving high-quality results.

Corn stalks

Corn cobs

Rice straw

Wheat stalks

Oat straw

Cotton stalks

Available straw Pellets

In addition to corn stalk pellets, it can also produce other types of pellets. The equipment features a robust pelletizing system capable of producing compact, uniform pellets. Regardless of the straw type, consistently high-quality results are achieved.

Should you require the production of mixed-ratio materials, this pelletizer remains equally suitable. The addition of wood chips to straw fuel is an effective strategy to enhance its calorific value. Our equipment is designed to maximize this advantage.

The straw pellets below are produced using our corn straw pellet machine. If you are looking for an industrial-grade pellet machine, you can trust us to provide the best solution.

corn stalk Pellets

Oat straw Pellets

Rice straw Pellets

Wheat stalks Pellets

corn cob Pellets

Cotton stalks Pellets

hay Pellets

Mixed Straw Pellets

Global CASES

Our pelletizing equipment has served customers in over 150 countries and regions worldwide. Our premium services have also earned high praise from clients. Whether you require individual corn stalk pellet machine or complete production line solutions, our products consistently deliver outstanding performance.

Corn Stalk Pellet Project in South Africa

The client has lots of waste corn stalks. They wanted to process these into 6 mm fuel pellets for boiler combustion. We supplied a corn pellet mill with a production capacity of 2.8–3.0 T/H. This equipment fully meets the production requirements.

Corn stalk Pellet Mill for Sale in Indonesia

This project uses rice straw, corn stalks and wood chips as raw materials. The client requires producing mixed-ratio straw pellets for sale. The product primarily addresses agricultural waste recycling. Therefore, we are offering a small-scale pellet mill.

romanian Biomass Straw Pellet making Plant

Our client operates a biomass pellet plant and requires high-quality straw pellets. We supplied a high-capacity corn straw pellet machine with a production capacity of 4-5 T/H. This equipment produces premium fuel, enhancing the economic returns.

Corn stalk pellet making machine for sale in Argentina

This project involves producing straw pellets for use as animal bedding. The raw materials are corn stalks and rice straw. Due to the high demand for loose pellets, we provided customized equipment. The production results fully meet the customer’s expectations.

High-Quality Straw Pellet Production Project in Poland

Our client required equipment capable of producing high-quality straw pellets. The target production capacity is 4 T/H. We provided customized pelletizer and other production equipment. The mixed straw pellet product meet the highest sales standards.

Automated Straw Pellet Production Project in USA

This project is a turnkey solution for straw pellet plant. Our client has substantial quantities of corn stalks and wheat straw. They require a highly automated corn straw pellet production line. With a capacity of 5-6 T/H, it offers an excellent return on investment.

Why Choose RICHI?

We offer industry-leading corn stalk pellet machine for sale.

RICHI Machinery was established in 1995, and we have remained dedicated to providing customers with the best pellet solutions. Our commitment to customer satisfaction drives us to research pellet machinery. To date, we have successfully supplied advanced corn stalk pellet maker to clients worldwide.

Drawing upon extensive customer service experience, we have a thorough understanding of your production needs and the challenges at every manufacturing stage. Consequently, we offer an integrated solution combining pre-sales and after-sales support to protect your corn stalk pellets production operations.

Our after-sales service includes a one-year warranty and a prompt response to any quality issues. To ensure rapid dispatch of components, we also maintain a global network of spare parts. If you encounter any production challenges, we will provide solutions to help you resume operations swiftly. We also offer the following services:

Free consultation Service

At RICHI, our experienced engineers and sales team offer free consultations on the corn stalk pellet making machine. We understand your production requirements and queries, so feel free to ask us any questions you have about the production solutions.

Customised Equipment Service

Should you have specific requirement for output and standard for pellets, we can provide tailored solutions to meet your needs. Our specialist technical team and large-scale manufacturing facilities can accommodate all your equipment needs.

Turnkey Production Solutions

Besides exceptional corn stalk pelletizer, our production line solutions have earned the trust and support of clients. The turnkey solutions, in particular, offer complete service including project planning, construction, equipment installation and operator training.

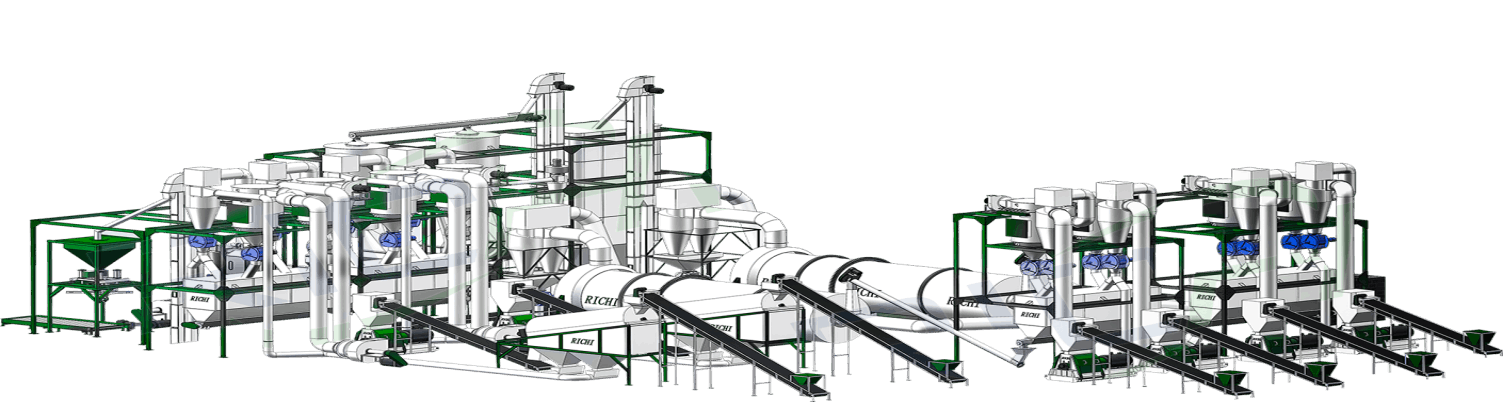

corn stalk Pellet Production Line

We not only supply advanced corn stalk pellet machines, but also provide highly efficient production lines. This solution is an industrial-grade straw pellet production line, with a capacity ranging from 0.5 to 40 T/H. The product incorporates scientifically organized process stages, thereby enhancing production efficiency. We also offer bespoke services and turnkey solutions.

01

Crushing

Corn stalks should be crushed into a powder before pelletization. At this stage, we supply robust crushers. These machines are designed to reduce the stalks to a powdery consistency of 3-5 mm.

02

Drying

If your corn stalk moisture content exceeds 18%, this processing stage is specifically tailored for you. We have designed an innovative large-scale drying cylinder to ensure the optimum moisture level.

03

Pelletizing

Our corn stalk pelletizer plays a pivotal role in this process. We will provide a suitable pelletizer model based on your production capacity. The appropriate die will be configured according to the required pellet size.

04

Cooling

This section is equipped with a highly efficient and energy-saving pellet cooling unit. It rapidly cools the pellets to ambient temperature levels, thereby ensuring the most stable structure.

05

Screening

Should you require uniformly sized pellets, this stage proves highly effective. It offers three distinct pellet size classifications. Concurrently, it separates other materials for secondary granulation.

06

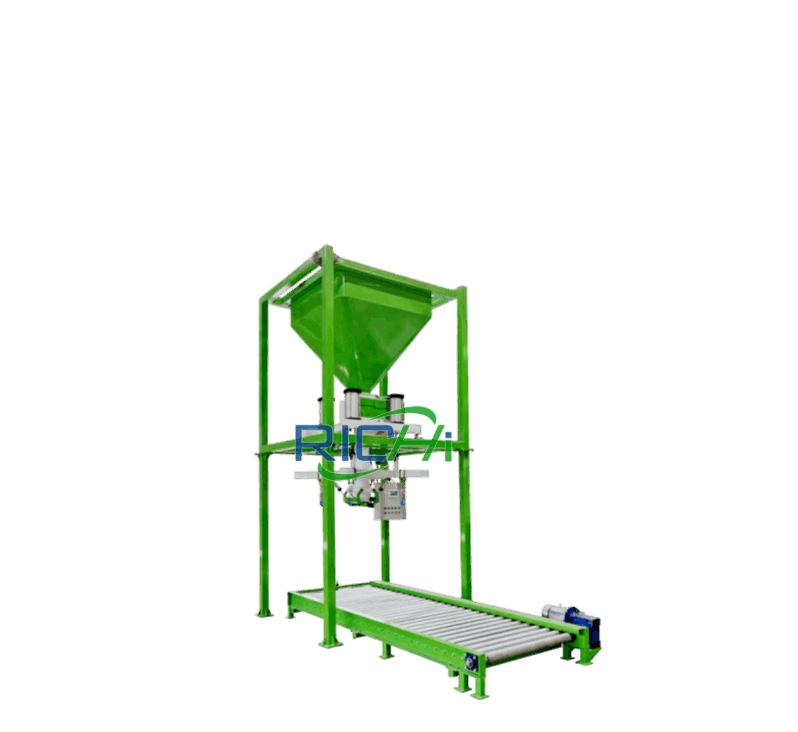

Packaging

We offer packaging equipment with varying levels of automation. You may select according to specific requirements. Fully automated packaging sections can reduce labour costs and minimize product loss.

Application Scenarios

Our equipment represents advanced industrial-grade machinery. It is suitable for biomass pellet plants of all scales. The high-quality pellets it produces meet stringent market standards, thus maximizing your return on investment.

In addition, our pellet mill boasts substantial energy-efficiency advantages. It is capable of processing a variety of straws, delivering higher calorific values and enhanced durability. Moreover, it is particularly well-suited for farms with substantial surplus straw resources.

We offer free consultations on production solutions around the clock.

We provide a one-stop service for corn stalk pellets production project.

biomass straw Pellet Plant

Farm

Rapid Customization Services

High Return on Investment

Other Related Production Equipment

In addition to corn stalk pellet machine, we also supply production equipment for other process stages. These include primary machinery and efficient material conveying systems. All our machines comply with multiple international environmental standards. RICHI can meet all your industrial-grade straw pellet production equipment needs.

Raw Material Crusher

It can grind hay and straw into a powder with size of 0.5-20 mm, and offer custom screen sizes.

Drum Dryer

It features a large capacity and a dual-barrel design for efficient, uniform drying of materials.

Cooling Machine

It rapidly cools high-temperature straw pellets to room temperature through counter-current cooling.

Packaging Scale

It provides fully automated weighing and uniform packaging. The sealing method options include thermoplastic sealing, seam sealing, or mixed sealing.

Other pellet machines

We have also designed other innovative pellet machines. Like the corn stalk pellet machine for sale, they offer energy-saving, eco-friendly and highly efficient performance. We are committed to providing you with premium pellet production in the long term.

alfalfa pellet machine

Our alfalfa pellet machine is ideal for meeting your high-standard feed requirements.

hemp pellet machine

We offer efficient hemp pellet machines that produce high-protein feed effectively.

EFB Pellet Machine

It features a robust pelletizing system for processing crop husks materials into pellets.

rice husk pellet machine

This machine produces both highly calorific clean fuel and high-quality animal feed.

Frequently Asked Questions

We fully understand your concerns when selecting a biomass corn stover pellet mill. Therefore, we have compiled answers to the following frequently asked questions. These cover equipment selection, raw material processing and services. For your convenience, we also provide round-the-clock equipment consultation support.

–

What other biomass materials can the corn stalk pellet machine process?

Our equipment boasts exceptional versatility. It not only handles straw materials, but is also ideal for producing grass pellets. The machine incorporates multiple innovative designs tailored for lightweight materials. Therefore, it delivers outstanding performance when producing forage pellets.

If you require equipment to blend corn stalks and forage grasses for feed production, we can provide customized solutions. Our turnkey solutions enable the construction of flexible corn straw pellet production lines.

–

What are the raw material requirements for producing corn straw pellets?

The pelletizing process for corn stover requires an appropriate moisture content and particle size. Corn stalks usually need to be crushed. The optimal particle size is 3-5 mm.

The ideal moisture content for pelleting is 15–18%. If your raw material has a higher moisture content, we recommend using drying equipment. We also provide complete corn stalk pellet production equipment.

–

What are the differences between corn stalk and wood chip pellet machine?

Corn stalk pellet mills are designed primarily for processing straw materials. Therefore, compared to wood pellet mills, they feature more specific enhancements.

For example, the roller system provides stronger compression, making it better suited to processing straw. Additionally, its ring die exhibits greater wear resistance, which is better suited to the pelletization of long-fiber straw.

–

What after-sales services do we provide for corn stalk pellet machines?

We offer comprehensive, long-term support. Each shipment includes a user manual and video tutorials to help you quickly learn to operate the machine. For production line projects, we also provide on-site equipment installation and technical training.

Each pelletizer also comes with a 12-month warranty. We have established a global spare parts network system for the shipment of wear-and-tear spare parts. We provide ongoing online guidance for any technical issues encountered during subsequent production. (View YouTube)

–

Can this corn stalk pellet machine produce products for export?

This is an advanced, industrial-grade machine. Therefore, it is fully capable of producing high-quality, export-grade pellets. However, this depends on your raw materials being properly processed to meet premium pelletization requirements.

We will provide optimal ring die dimensions and parameter adjustments for your pellet requirements. The robust system can accommodate varying production ratios. We also offer customized equipment and production line solutions to meet your needs for efficient, high-standard biomass pellet manufacturing.