Bamboo Pellet Machine

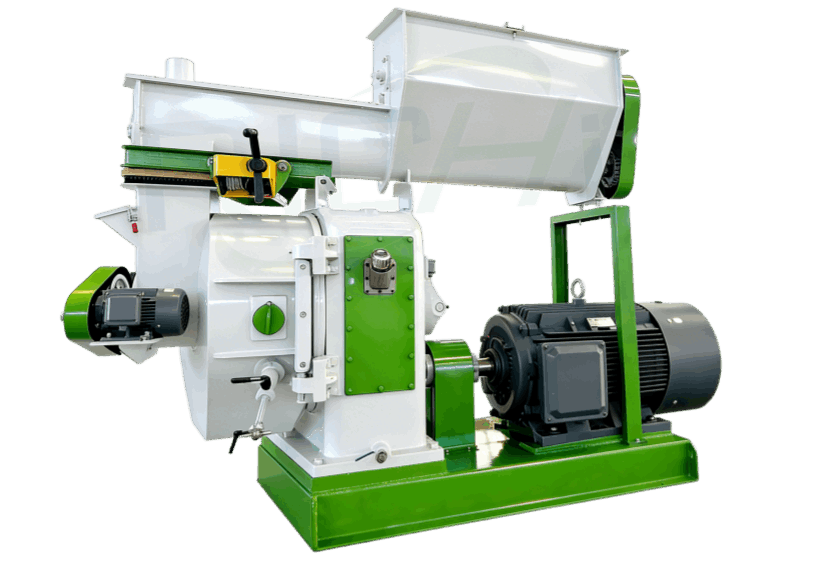

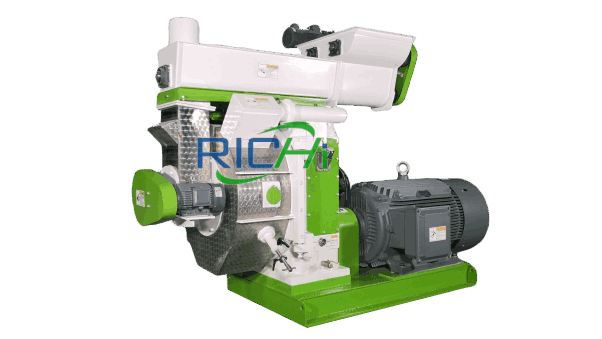

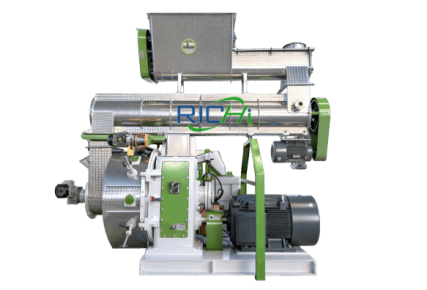

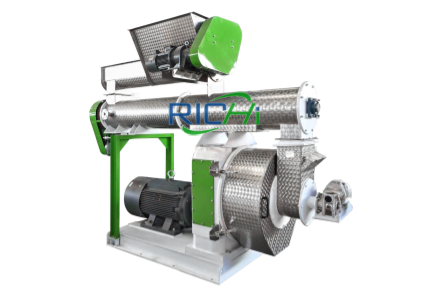

This bamboo pellet machine processes bamboo raw materials into high-quality biomass pellets. It is ideal for producing pellets from various types of bamboo waste with a high fiber content. We provide customized equipment to meet your industrial bamboo biomass pellet production needs.

bamboo Pellet machine For Sale

We are an advanced bamboo pellet mill manufacturer. These machines effectively address the issues of low forming efficiency and equipment wear when using bamboo materials. With a simple structure, they provide convenient operation.

Due to the lightweight nature of bamboo and its tendency to arch, both feed inlets of this bamboo pellet mill are fitted with anti-clogging devices. Each device has its own high-efficiency motor. These features ensure a smoother and more efficient pelletizing process.

To enhance the formation rate of bamboo pellets, our equipment uses dual rollers and innovative dies. Both components are made from strong alloy materials to enable consistent, stable production of high-quality bamboo pellets. The design also allows for a wider range of pellet sizes.

Parameters of bamboo Pellet mill

| Model | MZLH320 | MZLH350 | MZLH420 | MZLH520 | MZLH678 | MZLH768 |

| Main Motor Power(kw) | 22 | 37 | 90 | 132 | 185 | 250 |

| Breaker Feeder Power(kw) | 2.2 | 2.2 | 3 | 3 | 3 | 4 |

| Forced Feeder Power(kw) | 0.75 | 0.75 | 1.5 | 1.5 | 1.5 | 1.5 |

| Ring Die Inner Diameter(mm) | 320 | 350 | 420 | 520 | 673 | 762 |

| Pellet Diameter(mm) | 4-12 | |||||

| Capacity(T/H) | 0.5-0.6 | 1.0-1.2 | 1.8-2.0 | 2.8-3.0 | 4-5 | 6-8 |

The above details the specific models and production capacities of this industrial bamboo pellet machine. Each model is available for customization. If you require additional specifications or tailored solutions, please feel free to contact us.

Applications of bamboo Pellet machine

This pelletizer is highly adaptable. It can be used to pelletize various crushed agricultural and forestry residues, as well as other high-fiber, high-hardness biomass materials. It can produce biomass fuel for industrial boilers, heating systems, export and more.

Processable raw Materials

This pelletizer is a versatile industrial-grade machine. It can efficiently pelletize various bamboo materials, such as shavings, crushed chips and bamboo processing waste. Additionally, it is suitable for pelletizing a wide range of mixed biomass materials.

bamboo Chips

bamboo Sawdust

bamboo Shavings

Sugarcane bagasse

wood sawdust

wood Chips

coconut shell

Peanut shell

rice husk

empty fruit bunches

Available biomass Pellets

Our bamboo pellet machine can process raw materials into compact, high-energy biomass pellets. It delivers equally excellent results even when mixed with other materials.

These bamboo pellets can be carbonized to produce high-quality bamboo charcoal pellets, which significantly enhances product quality and calorific value. We also offer a full range of equipment for producing bamboo pellets.

Below are the pellet products manufactured using this biomass pellet machine. If you require a robust, industrial-grade machine, please feel free to enquire at any time.

bamboo sawdust Pellets

bamboo shaving Pellets

bamboo chips Pellets

Wood chip Pellets

wood sawdust Pellets

Bamboo Blended Pellets

bamboo charcoal pellet

Bagasse pellet

Innovation and Upgrading

To address the common issues of low pellet formation rates and equipment wear during bamboo pellet production, we have upgraded this bamboo pelletizer machine. These upgrades enable it to produce high-quality pellets more efficiently and consistently.

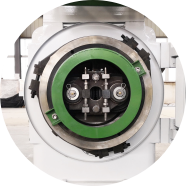

This pelletizer features an innovative dual-roller structure that more effectively handles bamboo with high fiber strength. When paired with an optimized ring die for the ideal compression ratio, it significantly enhances the efficiency of forming pellets.

Each bamboo pellet machine employs rollers and ring dies made from high-strength alloy steel 42 CrMo. We also subject them to a carburizing heat treatment to achieve superior surface hardness and wear resistance.

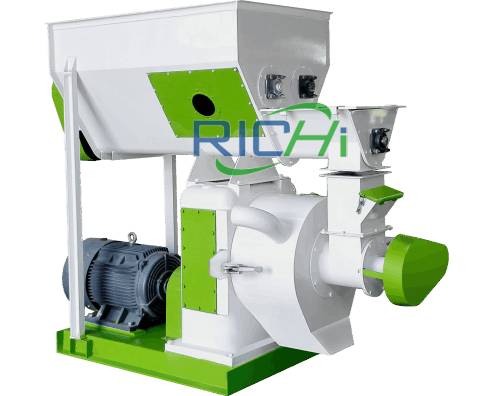

01

Arch-Breaking Feeder

This device consists of two sets of counter-rotating paddles, which facilitate the smooth feeding of material into the pelletizer.

02

Forced Feeder

It can push accumulated material into the pelletizing chamber. This enhances material utilization and production efficiency.

03

Pelletizing Chamber

The high-strength dual rollers and ring die are optimally assembled to achieve the ideal compression ratio consistently.

04

Exhaust Port

This port allows for the installation of a fan and cyclone to vent high-temperature steam from the pelletizing chamber without removing material.

05

Cutting Device

It can adjust the distance between the internal blade and the ring die. This allows pellets to be cut to different lengths.

06

Oil Injection System

It features a dedicated oil injection port and standard indicators, enabling you to better control the oil injection volume.

Production Process of bamboo Pellet machine

This equipment operates at a pelletizing temperature of 80°C, which activates the binding properties of its lignin. The following outlines the basic pelletizing process. We also offer customized designs.

- Feeding: The crushed bamboo chips enter the pelletizer via an arch-breaking or forced feeder.

- Compression: Under high-temperature steam conditions, the dual-pressure roller system compresses bamboo material into the mold.

- Forming: The cylindrical material is discharged continuously through the holes of the ring die.

- Cutting: Through blade cutting, the material becomes uniformly textured pellets of the ideal size.

After undergoing the above processing steps, the bamboo pellets become dense and compact. Once cooled and set, they attain a stable structure.

For biomass pellet manufacturer, rapid pellet cooling, screening and packaging processes are essential. Therefore, we have designed other high-efficiency equipment for bamboo pellet plants or other industrial-scale production lines. Feel free to contact us anytime for free consultation.

Advantages of bamboo Pellet machine

Our equipment offers multiple technical advantages and user-friendly performance. It is structurally simple for easy operation and maintenance, and significantly reduces production costs. This bamboo pellet press machine is the ideal solution for your industrial production needs.

Global CASES

Thanks to superior production performance and high utilization, this biomass pelletizer has been used in pellet production projects for customers worldwide. These include individual units sold to biomass pellet manufacturer, as well as bamboo pellet plant projects. It has consistently delivered outstanding results.

Bamboo Pellet machine for Sale in India

Our client has a biomass pellet plant with a capacity of 1.5–2 T/H. The raw materials are bamboo and wood chips. Accordingly, we supplied efficient pellet mill, raw material crusher and other necessary equipment.

Biomass Bamboo Pellet Production Project in Vietnam

This project requires high-quality bamboo fuel pellets with a diameter of 6 mm for export. The material consists of various bamboo processing waste. This high-capacity 2.8–3.0 T/H pellet mill effectively meets the production targets.

Bamboo Biomass Pellet machine For Sale in Indonesia

The customer required a pellet mill capable of processing multiple raw materials. Subsequently, we supplied a machine producing 8 mm diameter pellets, resolving their issues with accumulated bamboo and palm materials.

Bamboo Fuel Pellet Production Project in Thailand

This client primarily produces pellet fuel for industrial boilers and heating systems. Their raw materials are uncrushed bamboo and waste wood. We provided the client with cost-effective production line equipment.

Bamboo Waste Pellet Machine for Sale in Colombia

We supplied a small-capacity 1-1.2 T/H bamboo pelletizer for this project, capable of pelletizing bamboo sawdust and waste wood. The end product is primarily used for industrial combustion, so the pellet diameter is 8 mm.

Biomass Pellet Plant Project in Malaysia

It is a turnkey project with a production capacity of 2-3 T/H. Our client requires the production of 8 mm diameter pellet fuel. The production line incorporates a carbonization section to produce higher-quality products.

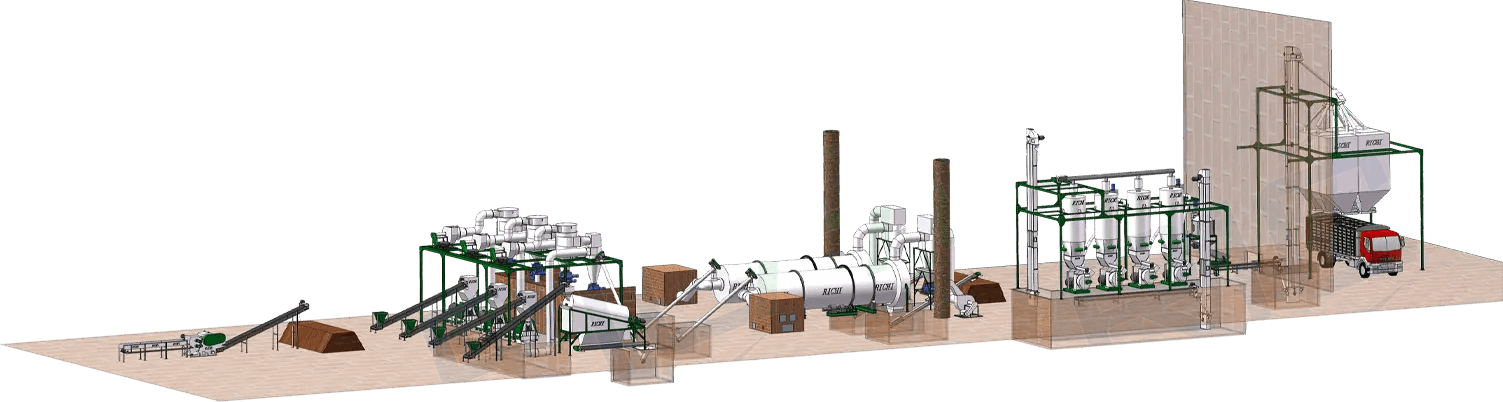

bamboo Pellet Production Line

In addition to advanced bamboo pellet machine, we also offer customized production line solutions. This biomass pellet production line is ideal for large-scale production, with capacities ranging from 0.6 to 40 T/H. We also offer turnkey solutions, including project planning, construction, installation, training and more, so you can enjoy a one-stop service.

01

Crushing

This section is designed for biomass materials with a diameter exceeding 5 mm that require crushing. Our high-efficiency crusher can uniformly process bamboo, wood and similar materials to meet pelletization needs.

02

Drying

If the moisture content of your raw material exceeds 18%, it will require this drying treatment. The convenient and efficient drying drums ensure optimal pellet moisture levels and facilitate easy adjustment of drying time.

03

Pelletizing

We have implemented multiple upgrades to our pelletizer for high-fiber, high-hardness raw materials. This effectively produces high-quality pellets while reducing wear. We offer a range of ring die apertures.

04

Cooling

If you require rapid pellet cooling, we provide this process stage. The cooling equipment here rapidly stabilizes pellet structure for subsequent processing. Its high level of automation prevents pellet breakage.

05

Screening

At this stage, you can obtain pellets in three sizes. Our dedicated pellet screeners can achieve optimal size distribution by using different mesh sizes. Additionally, excess material can enter a secondary pelletization.

06

Packaging

It is suitable for rapid pellet weighing and packaging requirements. Our highly automated packaging scales will reduce your labor costs and pellet loss while ensuring consistent packaging quality.

Application Scenarios

The production line solutions are suitable for biomass pellet plants, bamboo processing factories, biomass pellet export companies and industrial fuel manufacturers of all sizes. We can customize production stages according to your specific needs.

For turnkey biomass pellet plant solutions, we offer full project services. If you have any concerns regarding project planning, construction, equipment installation or worker training, this solution will provide you with peace of mind.

We offer free consultations on production equipment around the clock.

We provide a one-stop service for bamboo pellet production projects.

Biomass Pellet Plant

bamboo Processing Plant

Rapid Customization Services

High Return on Investment

Why Choose RICHI?

We offer industry-leading bamboo pellet machine for sale.

RICHI Machinery established since 1995, and we have consistently dedicated ourselves to providing customers with optimal pelletizing solutions. We prioritize customer satisfaction, delivering the best possible service.

Because of extensive customer service expertise, we deeply understand your production requirements. Therefore, we offer comprehensive pre-sales and after-sales support to safeguard your bamboo pellet production operations.

The comprehensive pre-sales service includes free consultations on bamboo pellet equipment. Our sales team is always available online to provide answers. We also provide attentive after-sales service, which includes the following specific services:

Long-Term Warranty

Every machine sold by RICHI comes with a one-year quality guarantee and fast shipping. For any quality issues arising during this period, you will receive prompt responses and proper resolutions.

Spare Parts Supply

We have also established a global spare parts supply network. Built upon a global system of warehouses, this network ensures the rapid shipment and timely replacement of your worn parts.

Technical Support

Beyond dedicated equipment manuals and instructional videos, we also offer installation and operational training for production line equipment, along with ongoing online technical guidance.

Other Related Production Equipment

Just like bamboo pellet machine, we provide a full range of equipment for bamboo pellet production lines. Below are the equipment types commonly selected by customers. Based on your production requirements, we will configure the appropriate equipment types. For this purpose, we also offer customized equipment solutions.

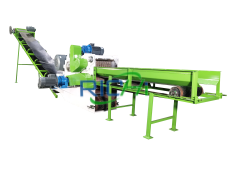

Drum Chipper

It can crush large-sized bamboo raw materials into 20-40 mm chips for subsequent processing. Its screen size can be customized.

Drum Dryer

This unit features a double-layer drying cylinder and spiral agitator blades. It dries high-moisture raw materials to the desired level.

Cooling Machine

It has a high level of automation, using cold air circulation to cool and set the pellets. The octagonal structure prevents pellet breakage.

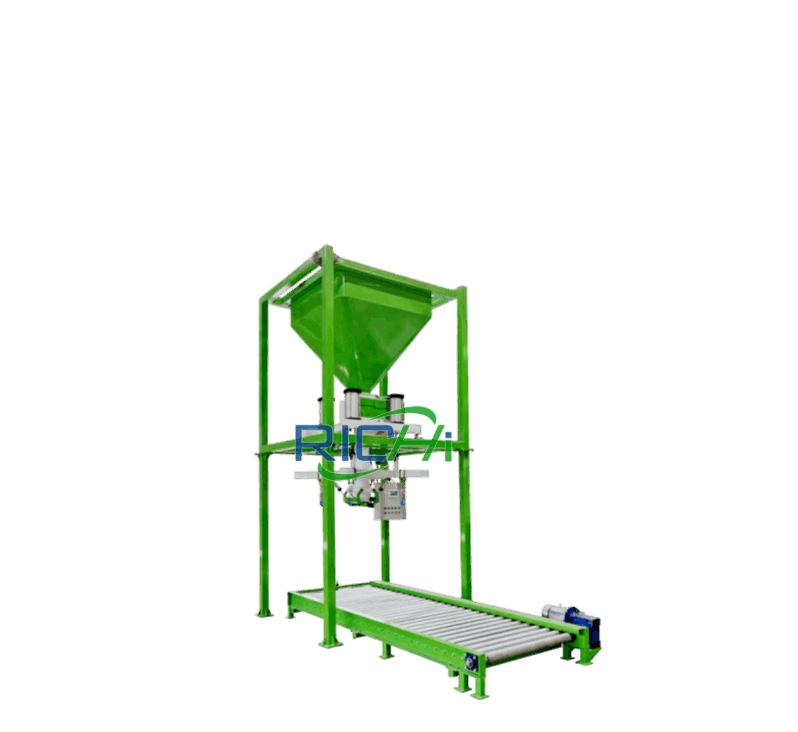

Packaging Scale

It provides fully automated weighing and uniform packaging. You may select thermoplastic, stitching, or hybrid sealing methods.

Other pellet machines

As a leading supplier of biomass pelletizers, we also offer a range of other high-efficiency pellet machine. Like the bamboo pellet machine, these devices can produce biomass fuel and other products, such as animal feed, bedding material and organic fertilizer. Please feel free to contact us for a complimentary consultation.

EFB Pellet Machine

It features a robust pelletizing system for processing hard-shelled materials into pellets.

rice husk pellet machine

This machine produces both highly calorific clean fuel and high-quality animal feed.

hay pellet machine

Our practical hay pellet machines can produce premium livestock feed and fuel pellets.

alfalfa pellet machine

Our alfalfa pellet machine is ideal for meeting your high-standard feed requirements.

Corn stalk pellet machine

We offer efficient corn stalk pellet machines that produce high calorific fuel pellets.

Frequently Asked Questions

If you have concerns about choosing a bamboo pelletizer, we will address each one for you. Below is a compilation of answers to frequently asked questions, which we hope will help you choose the right equipment. However, should you have any further questions, please feel free to consult us.

–

Is it difficult to pelletize bamboo?

Due to its naturally high fiber content and hardness, bamboo is more difficult to pelletize than wood. Therefore, conventional bamboo press machine often suffer from wear and compaction issues.

Our equipment features high-strength alloy dual rollers and ring dies. Their optimized structural design can handle various materials while consistently achieving optimal compression ratios. Therefore, selecting an industrial-grade bamboo pelletizer is crucial for stable, high-efficiency pellet production.

We also offer other equipment suitable for pelletizing high-fiber materials. These include wood chip pellet machine, peanut shell pellet machine, hemp pellet machine, and more.

–

What are the requirements for raw materials in a bamboo pellet machine?

The ideal raw material size should be within 3-5 mm. Uneven crushing can easily cause wear to components and reduce output. Additionally, the ideal moisture content for pelletizing is around 15%. If the moisture content of your raw materials is unsuitable, it will affect the forming results.

Therefore, maintaining consistent, high-quality pelletization in the long term requires properly handling the raw materials. These requirements apply equally to other pellet machines, such as wheat straw pellet machine, rice straw pellet machine, miscanthus pellet machine, and more.

–

What is the most common pellet diameter produced by bamboo biomass pellet mills?

This primarily depends on your intended pellet application. Generally, small to medium-sized combustion systems primarily use pellets with a diameter of 6 mm. Examples include small boiler combustion, residential heating, small-area heating, and export markets.

Additionally, industrial-grade pellet fuel typically requires a diameter of 8-10 mm. For example, industrial boilers and industrial combustion power generation. Pellet fuel with an 8 mm diameter offers the most stable quality and is the most common.(View YouTube)

–

What is the minimum production capacity suitable for a bamboo pellet machine?

Due to the high hardness of bamboo, the output per unit is lower than that of wood pellet production. Our single pellet machine has a minimum capacity of 0.5 T/H and a maximum capacity of 8 T/H, suitable for industrial-scale biomass pellet production.

If your investment scale is small, your budget is limited, and your raw material supply is unstable, we recommend careful evaluation. Bamboo pelletization requires higher equipment specifications and is not suitable for low-specification or home workshop production projects.

–

How to determine whether to invest in a bamboo pellet machine?

This depends on three main factors: a stable supply of raw materials, the ability to produce pellets on a large scale, and a long-term operational plan. Based on these factors, you can then assess whether investing in an industrial-grade pelletizer is necessary.

If your production could be impacted by shortages of raw materials, small-batch production or prolonged downtime, it is advisable to conduct a thorough technical evaluation first.