Bagasse Pellet Machine

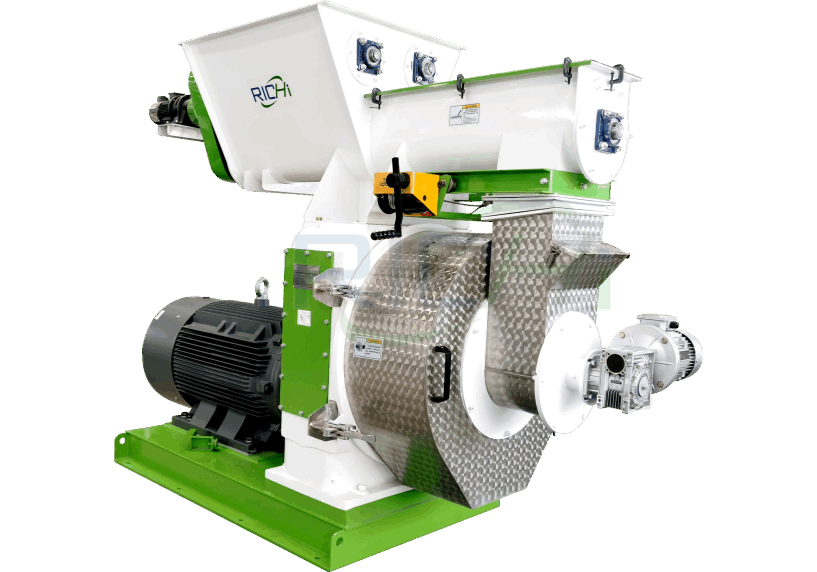

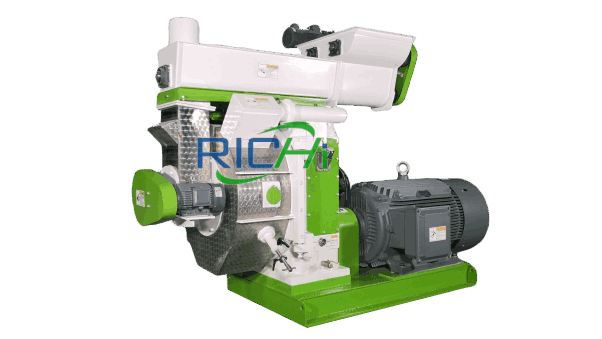

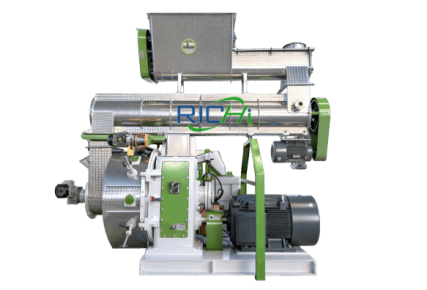

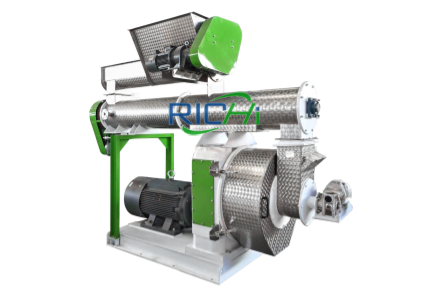

This industrial bagasse pellet machine can convert sugarcane bagasse into hard, high-density pellets. It features an efficient pelletizing system for processing fibrous biomass materials. We also offer customized equipment and complete production solutions.

bagasse Pellet machine For Sale

We provide efficient pelletizer solutions, including customized production capacity and ring die sizes. With this equipment, you can achieve stable and efficient large-scale bagasse pellet production.

The equipment features a well-designed structure for convenient operation and routine maintenance. Whether you require bagasse pellets for fuel or animal feed, this machine performs flawlessly. We will customize equipment components and parameters according to your specific production needs.

With a production capacity ranging from 0.5 to 8 T/H, this pelletizer is ideal for large-scale bagasse pellet production. The resulting pellets have a diameter ranging from 4 to 12 mm, with lengths reaching 4 to 5 times their diameter. Its high utilization rate delivers greater returns on investment for you.

Parameters of bagasse Pellet mill

| Model | MZLH320 | MZLH350 | MZLH420 | MZLH520 | MZLH678 | MZLH768 |

| Main Motor Power(kw) | 22 | 37 | 90 | 132 | 185 | 250 |

| Breaker Feeder Power(kw) | 2.2 | 2.2 | 3 | 3 | 3 | 4 |

| Forced Feeder Power(kw) | 0.75 | 0.75 | 1.5 | 1.5 | 1.5 | 1.5 |

| Ring Die Inner Diameter(mm) | 320 | 350 | 420 | 520 | 673 | 762 |

| Pellet Diameter(mm) | 4-12 | |||||

| Capacity(T/H) | 0.5-0.6 | 1.0-1.2 | 1.8-2.0 | 2.8-3.0 | 4-5 | 6-8 |

We offer a range of models and production capacities for this bagasse pellet machine, which can support bagasse pellet production lines with capacities ranging from 0.5 to 40 T/H. We also offer customized designs for specific parameter requirements.

Applications of bagasse Pellet machine

This industrial-grade pelletizer boasts high utilization efficiency. It can pelletize single or blended high-fiber raw materials. It enables you to produce a variety of biomass pellets to meet various application needs.

Processable raw Materials

Based on the characteristics of sugarcane bagasse, we have improved the wear resistance and forming capability of the equipment. Consequently, it is equally suitable for pelletizing tasks involving other high-fiber raw materials. Whether you use a single raw material or a mixture, it maintains stable output.

Bagasse

Sugarcane Leaf

Empty Fruit Bunch

Palm fiber

Rice Husk

straw

finished Pellet products

Sugarcane bagasse pellets are primarily used as biomass fuel. They can be utilized in industrial boilers, biomass power generation, district heating, and similar applications.

Additionally, if you need to produce animal feed, it is equally suitable. You can achieve high-quality feeding results by mixing and pelletizing them with corn, soybean meal, and other ingredients.

Below are the pellet products produced by this pelletizer. They are compact and plump, meeting stricter sales standards. Contact us for a free equipment consultation.

bagasse pellets

Sugarcane Leaf Pellets

EFB Pellets

straw pellets

sorghum stalk pellets

corn cob pellets

Peanut Shell Pellets

Mixed Biomass Pellets

Innovation and Upgrading

Traditional bagasse pellet machine suffer from low forming rates, high energy consumption, and susceptibility to wear. Our equipment has undergone innovative upgrades to effectively overcome these issues, delivering optimal production results for you.

To address clogging issues during sugarcane pelletization, we have specifically designed a dual-roller structure. It improves the compression of high-fiber, lightweight materials. All wear-prone components utilize 42 CrMo alloy to provide superior abrasion resistance.

For convenient feeding, we have incorporated dual feed ports. Each port is fitted with anti-clogging devices and dedicated motors to ensure smooth material flow and increased production efficiency.

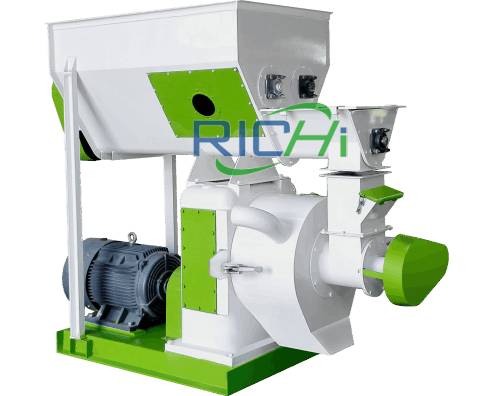

01

Arch-Breaking Feeder

Installed here is a variable-frequency impeller feeder, whose rotation prevents lightweight materials from accumulating at the feed inlet.

02

Forced Feeder

It can push accumulated material into the pelletizing chamber. This enhances material utilization and production efficiency.

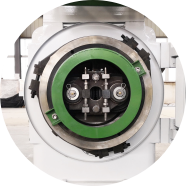

03

Pelletizing Chamber

The primary structure consists of a clamp-type ring die and a dual-roll system, which work together achieve optimal pelletizing results.

04

Exhaust Port

This port allows for the installation of a fan and cyclone to vent high-temperature steam from the pelletizing chamber without removing material.

05

Cutting Device

You can use it to adjust and secure the distance between the blade and the ring die, enabling to cut pellets of different lengths.

06

Oil Injection System

This device enables you to add lubricating grease to internal parts. There is an inspection port below to easily control the amount added.

Production Process of bagasse Pellet machine

The pelletizing temperature of this equipment is 80°C, which effectively enhances material cohesion and promotes molding. Below is the complete pelletizing process.

- Feeding: The crushed bagasse materials enter the pelletizer via an arch-breaking or forced feeder.

- Compression: Under high-temperature steam conditions, the dual-pressure roller system compresses them into the mold.

- Forming: The cylindrical material is discharged continuously through the holes of the ring die.

- Cutting: Through blade cutting, the material becomes uniformly textured pellets of the ideal size.

After undergoing the above processing steps, the bagasse pellets become dense and compact. Once cooled and set, they attain a stable structure.

The above outlines the production process for biomass bagasse pellets. If your goal is to produce feed pellets, incorporating a conditioner will achieve better material gelatinization. Additionally, we offer pellet cooling, screening, and packaging systems. Feel free to contact us anytime for inquiries.

Advantages of bagasse Pellet mill

This bagasse pellet machine boasts multiple technological advantages that significantly extend its service life. It not only delivers an efficient and energy-saving production experience, but also reduces costs to maximize your return on investment.

Global CASES

Our pelletizer projects span over 150 countries and regions worldwide. This success is due to our advanced production equipment and premium service. These projects cover individual bagasse pellet mill for sale and complete production line installations. Each one delivers optimal outcomes for pellet production and high return on investment.

Sugarcane bagasse pellet machine for sale in Thailand

The client is a sugar mill with abundant sugarcane bagasse. They require a pellet mill with a capacity of 3-4 T/H, as well as other production equipment. The resulting pellets are primarily used in industrial boilers.

Sugarcane Bagasse Pellet Production Project in Brazil

This biomass pellet manufacturer uses bagasse and wood chips as material. The target product is used in industrial boilers or power plants. We provided a complete bagasse pelletizing system and other necessary equipment.

Bagasse Pellet Production Project in Indonesia

In this project, our 1.8-2.0 T/H pellet mill produces biomass fuel for sale. The raw materials used are sugarcane bagasse and empty fruit bunches, which enhance the calorific value of the finished pellets.

Bagasse Pellet Making Machine for Sale in India

As the client is a large sugar mill, which has abundant raw materials and high capacity need, we provided a customized 3 T/H pelletizer. This machine fully meets the client’s requirement for 100% bagasse pelletization.

Biomass Bagasse Pellet Plant in Philippines

Our client operates a biomass pellet plant with capacity of 2–3 T/H. We offered a flexible equipment configuration that enables bagasse and rice husk mixture to pelletized, providing greater economic benefits.

biomass Bagasse Pellet Press for Sale in Pakistan

This project serves an industrial boiler user. The materials are bagasse, rice husks and straw. Thanks to this 1-2 T/H pelletizing equipment, our clients have successfully reduced their production costs and energy consumption.

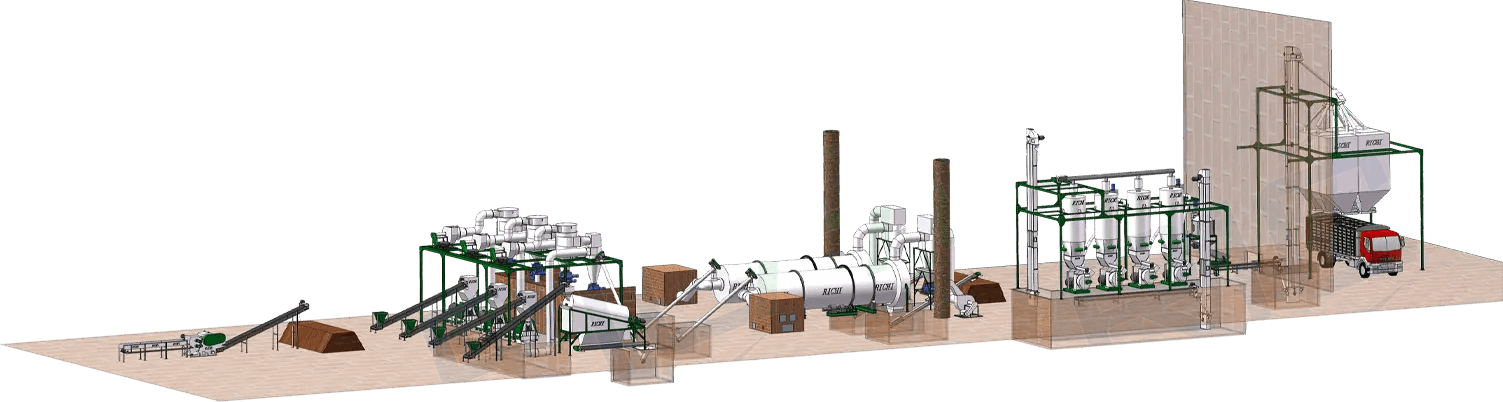

bagasse Pellet Production Line

Bagasse pellet machine is the core equipment of this production line. This system is ideal for industrial-scale production of sugarcane pellets, with capacities ranging from 1.5 to 40 T/H. It features scientifically divided process stages and higher automation level. We also offer customized solutions and turnkey project services.

01

Crushing

Sugarcane bagasse has a high fiber content. Therefore, it requires pulverization before pelletization. This process can crush the bagasse to a size of 3-5 mm to facilitate pellet formation.

02

Drying

The moisture content of bagasse typically ranges between 40% and 50%, making direct pelletization difficult to achieve. This process dries the bagasse to an ideal moisture level of 15–18% for pelletization.

03

Pelletizing

We will provide the appropriate pellet mill configuration based on your raw material ratio, target production capacity, and pellet size. For feed pellet production, the pelletizer will be equipped with a conditioner.

04

Cooling

To ensure rapid pellet setting, you can choose to configure this section. This cooling system enables the pellet structure to set quickly without losing integrity, making it easier to package.

05

Screening

This section can screen three types of pellet product to meet requirements for different pellet sizes. The excess material removed during screening can undergo secondary pelletization, thereby reducing costs.

06

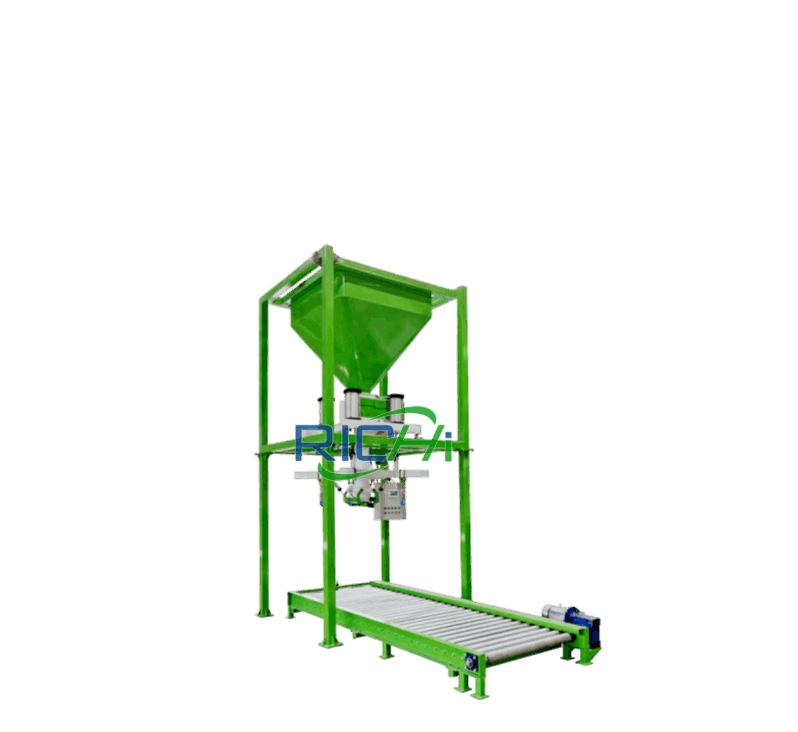

Packaging

It is suitable for rapid pellet weighing and packaging requirements. Our highly automated packaging scales will reduce your labor costs and pellet loss while ensuring consistent packaging quality.

Application Scenarios

To meet diverse automation requirements, we offer two solutions: fully automated production lines and disconnect lines. You may select based on your factory space, target production capacity, and investment budget.

For large-scale manufacturers requiring rapid production deployment, our turnkey solution is available. This comprehensive service covers project planning, construction, training, commissioning and subsequent phases.

We offer free consultations on production equipment around the clock.

We provide a one-stop service for bagasse pellet production projects.

Biomass Pellet Plant

Sugar Manufacturing Plant

Rapid Customization Services

High Return on Investment

Why Choose RICHI?

We provide industrial-grade pellet production solutions and one-stop services.

RICHI Machinery established since 1995, and we have consistently dedicated ourselves to providing customers with optimal pelletizing solutions. We prioritize customer satisfaction, delivering the best possible service.

Because of extensive customer service expertise, we deeply understand your production requirements. Therefore, we offer comprehensive pre-sales and after-sales support to safeguard your bagasse pellet production operations.

The comprehensive pre-sales service includes free consultations on bagasse pellet machine. Our sales team is always available online to provide answers. We also provide attentive after-sales service, which includes the following specific services:

Long-Term Warranty

Every machine sold by RICHI comes with a one-year quality guarantee and fast shipping. For any quality issues arising during this period, you will receive prompt responses and proper resolutions.

Spare Parts Supply

We have also established a global spare parts supply network. Built upon a global system of warehouses, this network ensures the rapid shipment and timely replacement of your worn parts.

Technical Support

Beyond dedicated equipment manuals and instructional videos, we also offer installation and operational training for production line equipment, along with ongoing online technical guidance.

Other Related Production Equipment

As a leading bagasse pellet machine supplier, we also provide complete bagasse pellet production line equipment. Below are the commonly used equipment models for key process stages. We also offer bespoke bagasse pellet plant solutions. Please feel free to get in touch at any time.

Raw Material Shredder

It can crush irregularly shaped sugarcane bagasse preliminarily, processing the material to a size of approximately 3 cm. The number of cutter discs and teeth can be customized.

Drum Dryer

This device uses a double-layer drying drum design to achieve an ideal moisture content of 15–18% in materials. The drying time is adjustable.

Cooling Machine

The principle of operation involves cooling pellets through convection with cold air. Its octagonal structure prevents pellet damage.

Packaging Scale

It provides fully automated weighing and uniform packaging. You may select thermoplastic, stitching, or hybrid sealing methods.

Other pellet machines

Besides advanced bagasse pellet machine, we design and manufacture other industrial biomass pellet machines. These machines also offer high efficiency and energy savings. They can manufacture pellets for high-quality fuel, animal feed, bedding, organic fertilizer and more.

bamboo pellet machine

It features a robust pelletizing system for processing high fiber bamboo into pellets.

wood chip pellet machine

The device can pelletize various types of wood into high-calorific wood pellets of multiple sizes.

hay pellet machine

Our practical hay pellet machines can produce premium livestock feed and fuel pellets.

alfalfa pellet machine

Our alfalfa pellet machine is ideal for meeting your high-standard feed requirements.

Corn stalk pellet machine

We offer efficient corn stalk pellet machines that produce high calorific fuel pellets.

Frequently Asked Questions

With years of customer service experience, we understand your concerns and uncertainties when selecting a bagasse pelletizer. Below, you will find some detailed answers that may help. If you have any further questions, please feel free to contact us with details of your raw materials and target production capacity.

–

Can the bagasse pellet machine pelletize 100% sugarcane bagasse?

Absolutely. Both the ring die and roller shells of this pelletizer are crafted from high-hardness alloy materials. Furthermore, they undergo carburizing heat treatment for enhanced wear resistance. Consequently, it can effectively handle the pelletization of high-fibre, pure sugarcane bagasse. This production method is commonly employed in sugarcane plantations and sugar factories.

However, for biomass pellet manufacturers, 100% bagasse is not the most optimal material composition. To enhance pellet formation rates and calorific value, it is advisable to blend in appropriate quantities of other biomass materials such as wood shavings or rice husks.

–

What is the production capacity range applicable to the bagasse pellet making machine?

Our equipment is industrial grade. The minimum production capacity is 0.5 T/H. For small- to medium-scale pellet production, we recommend selecting models with a capacity of 1–3 T/H. Pelletizers with capacities of 4–8 T/H are usually customized solutions. We offer a range of models with different capacities.

–

What are the main applications of sugarcane bagasse pellets?

Their main use is as a biomass fuel. As a clean energy source, they can power boilers and heating systems and generate electricity. They offer lower costs and reduced combustion emissions compared to coal.

We also supply biomass pellet machines that can produce high-quality fuel. Examples include sawdust pellet machine, rice husk pellet machine, EFB pellet machine, peanut shell pellet machine, and more.

Additionally, sugarcane bagasse is rich in dietary fiber and sugars. Consequently, it can be mixed with ingredients such as soybean meal and maize to create pellets. The resulting pellets serve as feed for ruminant animals. For this application, the sugarcane bagasse pellet machine requires the addition of a conditioner. (View YouTube)

–

Is the bagasse pellet machine more suitable for producing biomass fuel or feed?

The most common application is producing biomass fuel. However, our bagasse pelletizer is a versatile industrial unit. It can produce both biomass fuel pellets and pelletized animal feed. We will increase the number of conditioners according to your production requirements.

Should you require alternative pellet machines capable of producing both fuel and feed pellets, we can supply hemp pellet machine, miscanthus pellet machine, rice straw pellet machine, wheat straw pellet machine, and others.

–

Does sugarcane bagasse require specialized crushing equipment?

Sugarcane bagasse typically constitutes waste material following mechanical pressing. Retaining most of its long fibres, it proves difficult to pelletize directly. Consequently, dedicated pulverising equipment is necessary. The pulverisation process involves primary crushing and fine grinding.

When crushed uniformly, bagasse with a particle size of 3–5 mm facilitates easier pelletization. We can supply highly efficient, energy-saving crushing systems, as well as processing equipment for other process stages. These solutions offer maximum convenience and superior results for your bagasse pellet production.