Alfalfa Pellet Production Line

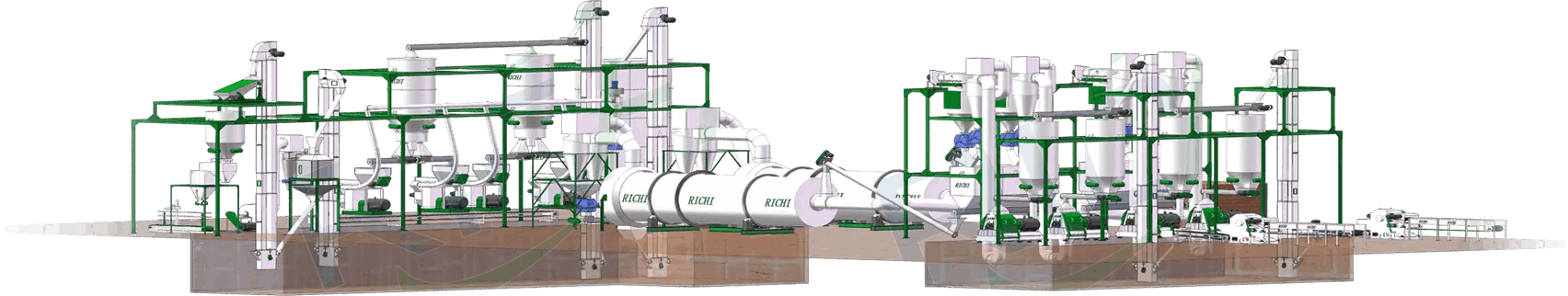

This alfalfa pellet production line is a highly modernized industrial solution. It features a scientifically organized system, efficient equipment, and advanced control systems. Consequently, it can produce nutritious and tasty alfalfa pellets. Contact us to receive your customized design solution.

CHOOSE PROFESSIONAL

alfalfa PELLET PRODUCTION solution

Our offer alfalfa pellet processing line that can produce pellets ranging from 4-12 mm in diameter. We can adjust the parameters of the specific equipment according to your production targets, thus fulfilling your precise pellet specifications.

Additionally, we also offer a one-stop turnkey solution for this production line. It includes production line planning, on-site construction, equipment installation and commissioning, operator training and more. We provide full-process production assurance for your alfalfa pellet plants.

We have thoroughly researched potential challenges in alfalfa pellet production. This solution is therefore designed based on real customer production needs. Each process segment is equipped with high-efficiency main machinery. In addition to efficient pelletizers, we can configure raw material handling systems and pellet packaging equipment according to your requirements.

Complete process flow

We can provide customized production processes.

Crushing

Drying

Pelletizing

Cooling

Screening

Packaging

Applications of alfalfa Pellet Production Line

This alfalfa pellet processing line has a wide range of applications. It can produce alfalfa feed suitable for ruminants, livestock and pets. Each type of pellets can provide perfect quality and feeding results. We can tailor a production line solution to your specific requirements.

Working Process of Alfalfa Pellet Production Line

To make your alfalfa pellet processing line more efficient and convenient, we have divided this process into distinct stages. Each stage combines robust operational systems with flexibility. Accordingly, we offer varying levels of automation and customizable processes.

01

Crushing Section

This section is equipped with powerful forage crushers, which effortlessly reduce raw materials into powdered particles measuring 3–5 mm or smaller. The enlarged capacity design of these crushers allows for higher unit output.

02

Drying Section

We have designed an innovative drying system to facilitate the processing of alfalfa with a high moisture content. This drying drum features a dual-cylinder design, which evenly dries the grass powder to achieve an ideal moisture level of 15–18%.

03

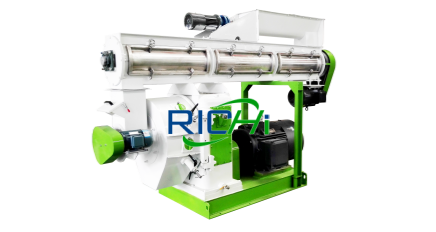

Pelletizing Section

The alfalfa grass pellet machine plays a key role in this process and is essential for the alfalfa pellet manufacturing line. It boasts highly efficient anti-bridging and pelletizing capabilities, which enhance the formation rates of alfalfa pellets and reduce material loss.

04

Cooling Section

Freshly produced alfalfa pellets are moist and soft, which makes them difficult to package and transport. This counterflow cooler can quickly cool the surfaces of the pellets. Once cooled to room temperature, the alfalfa pellets achieve a stable structure.

05

Screening Section

We provide specialized screening equipment for alfalfa pellets to ensure uniform specifications for sale. This rotary classifier can separate standard pellets from other materials, making secondary pelletization easier and reducing costs.

06

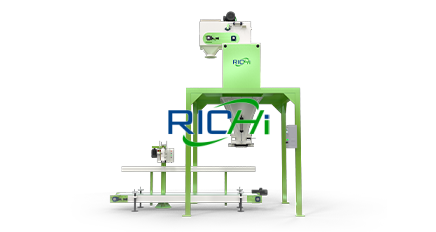

Packaging Section

At this stage, we have designed multiple packaging solutions featuring different levels of automation and packaging methods. The fully automated packaging scales enable automated weighing and packaging, thereby reducing material waste and labor costs.

The above outlines the basic workflow of this production line. We can design customized solutions based on the characteristics of your raw materials and the application requirements of your pellets. We also offer a one-stop turnkey service, which enables you to achieve efficient and easy production.

Applicable Raw Materials

The alfalfa pellet production line has an excellent degree of versatility. Beyond alfalfa hay, it efficiently processes other grass materials. The following raw materials can also be transformed into high-quality pellets.

Alfalfa

Clover

Hemp

oat grass

Peppermint

Hay

Miscanthus

Leymus chinensis

Cattail grass

Rye grass

We have implemented targeted optimizations to equipment on alfalfa pellet production system. These include anti-bridging devices, increased capacity designs, and high-efficiency conditioning systems. Therefore, they can also efficiently handle various other grass. Furthermore, we can also provide customized production solutions for special raw materials.

The perfect Pellets produced By alfalfa pellet production line

Thousands of customers have successfully produced premium alfalfa pellets with our highly efficient production line solutions. This production line suits the manufacture of various alfalfa pellet formulations and other grass pellets equally well. Choose us and you can also produce perfect pellets.

alfalfa pellets

These pellets undergo a scientific conditioning and pelleting process. Consequently, they have a compact texture, high nutritional value and are easy to consume. They suit the feeding of cattle, horses, rabbits, sheep and other animals.

hemp pellets

This production line can also compress hemp seeds and meal, as well as similar materials, into high-quality feed for ruminants. The pellets retain the abundant fiber and nutrients present in the raw materials.

clover pellets

Our alfalfa pellet processing line can also produce clover pellets. Whether you need to process fresh clover or hay, the highly efficient pelleting system can handle both with ease. The result is high-quality forage pellets.

oat grass pellets

This production line features a highly efficient system for processing oat grass, such as oat hay and bales of oat straw, into a fine powder. The resulting oat straw pellets have an excellent structure, making them ideal for use as roughage for cattle and sheep.

Customized Capacity for alfalfa Pellet Production Line

We offer multiple customized capacity solutions to meet diverse needs for alfalfa pellet manufacturing line. The robust processing capacity can meet demands ranging from 0.5 to 40 T/H. If you require additional capacities, please feel free to contact us at any time.

0.5-40 T/H

alfalfa Pellet processing Line

This alfalfa grass pellet production line features a standard capacity model. It offers exceptional adaptability to different materials, delivering outstanding production results. For this reason, it has earned the trust and support of many alfalfa pellet manufacturers and livestock farms.

0.5-1 T/H

1-2 T/H

2-3 T/H

3-4 T/H

5-6 T/H

8-10 T/H

11-15 T/H

15-20 T/H

20-40 T/H

Equipment on alfalfa Pellet Production Line

Raw Material Crusher

This machine is designed specifically for crushing grass and straw. Its enlarged feed inlet and arch-breaking device enable efficient crushing. The result is a powdery material with a particle size of 3–5 mm.

Raw Material Mixer

With the larger capacity, it can mix more raw materials at once, making it ideal for producing pellets from multiple ingredients. The resulting grass powder allows each pellet to deliver comprehensive nutritional value.

Drum Dryer

This equipment features a dual-barrel design. With an internal spiral conveyor plate, it enables rapid and uniform drying. Its large capacity reduces drying time and enhances production efficiency.

alfalfa Pellet Machine

The scientific structure of this pelletizer makes it highly efficient and energy-saving. With the robust roller system and innovative die ratio, it consistently produces high-quality alfalfa pellets.

Counterflow Cooler

It can rapidly lower the temperature of pellets by using cyclic convection between the pellets and air. Cooled alfalfa pellets have a more stable structure. This device can operate with a vibrating screen.

Rotary Grade Screen

It offers three screening sizes, enabling simultaneous separation of finished pellets with different diameters. It provides high screening precision with minimal vibration. It can also remove powder for re-granulation.

The above outlines the main components of this alfalfa pellet production line. In addition to these, we have designed convenient, efficient auxiliary devices. For example, we offer U-shaped screw conveyors, pneumatic conveying systems, storage bins and air cannons. If you are interested in these devices, please feel free to contact us.

Global CASES

With over three decades of specialized expertise, RICHI Machinery can deliver ideal customized solutions that are tailored to client needs. The following are alfalfa pellet plant solutions for customers worldwide. Our turnkey solutions, in particular, enable customers to produce more quickly and conveniently.

CUSTOMER REVIEWS

Following years of dedicated effort, our alfalfa pellet production line has earned the favor of customers worldwide. Feedback from farms, ranches, livestock operations and alfalfa pellet manufacturers worldwide has been overwhelmingly positive. The following words offer insights into the user experience with these systems.

Click to chat with us online

Operational Video of Alfalfa Pellet Production Line

Until now, we have delivered our alfalfa pellet production system to over 150 countries and regions worldwide. Our advanced equipment and full service system provide continuous support for our clients’ full-cycle production. Below are some videos which show you some of these solutions.

Alfalfa Pellets In the Production Line

the Pelletizing Process

4 T/H alfalfa Pellet Production Line

Frequently Asked Questions

We have extensive experience in customer service. As a result, we understand the challenges you may face when choosing a alfalfa pellet making line. Therefore, we have put together the following answers to help you find out more. For any questions about this solution or equipment, please get in touch.

What are the raw material requirements for the alfalfa pellet making line?

+

The basic pelletizing conditions must be met, including three aspects: cleanliness of the raw material, moisture content and particle size. Our production line equipment can perfectly achieve all these requirements.

Firstly, clean raw materials are essential for producing high-quality feed pellets. Free from impurities, they ensure pellet quality and prevent equipment wear. Secondly, the ideal moisture content is between 15% and 18%. Excessive or insufficient moisture adversely affects the formation rate of pellets. Finally, an optimal particle size for grass powder material is 3-5 mm.

What is the main purpose of alfalfa pellets produced by this production line?

+

Alfalfa pellets are a high-quality source of roughage for ruminants such as dairy cows, beef cattle and sheep. Similarly, they can be used to feed certain herbivorous animals, including specialty breeds such as rabbits, foxes and deer.

Is the alfalfa pellet production line energy-intensive and costly to operate?

+

All of our production line equipment features energy-efficient designs that reduce energy consumption by 20%. Consequently, this line offers high efficiency and environmental benefits.

Primary operating costs include sourcing raw materials, minimal electricity consumption and replacing wear parts such as ring dies and press rollers.

Our press roller system and ring dies utilize food-grade stainless steel and alloy materials, which enhance wear resistance and extend the service life. Please note that proper equipment maintenance and standardized operation are essential for controlling costs and maintaining profitability.

How long does it take to recoup the investment in an alfalfa pellet production line?

+

This production line has an excellent capacity, which will maximize your return on investment. Therefore, your actual payback period depends on the cost of raw materials, the selling price of finished pellets, and operational efficiency.

We provide the most cost-effective production solution. With a stable supply of raw materials and consistent sales, the investment can typically be recovered within one to three years. We offer timely technical support for any subsequent production issues to help you run your pellet business.

Which services are included in our turnkey production line solutions?

+

During the initial project phase, we provide customized project planning based on actual conditions and production requirements. We select suitable production equipment according to the project plan and install control systems tailored to your chosen level of automation. We deploy a dedicated engineering team to deliver on-site construction services.

During the mid-phase of the project, we handle equipment installation and commissioning, as well as production line trial runs, to ensure seamless integration and optimal operational performance. Furthermore, our engineers will provide your staff with operational training to facilitate a swift ramp-up in production.

Finally, we implement rigorous acceptance procedures to ensure the production line is implemented flawlessly. Our comprehensive after-sales support package includes a one-year warranty, fast spare parts delivery and long-term technical assistance. (YouTube Channel)