What is the raw material for your pellet production?

Our biomass pellet machine for sale is suitable for pellet production from various raw materials. With experience of serving thousands of customers, we have a deep understanding of your production needs and concerns. RICHI pellet production equipment comes in diverse models with strong adaptability, meeting all requirements for producing wood pellets, grass pellets, straw pellets, and husk pellets.

Raw Materials of Wood Pellets

The common raw materials for wood pellets include various waste wood and agricultural residues, such as large-diameter logs, small wood chips. We provides powerful wood crushers and wood pellet machines that can easily process wood materials and produce perfect wood pellets.

Logs

Straw

Branches

Corn stalks

Wood pieces

Wood Shavings

Wood chips

Wood Boards

Raw Materials of Grass Pellets

Given the high moisture content, arching tendencies of grass materials, we incorporate high-efficiency drum dryers and grass pellet machines. These ensure optimal pelletization conditions for the feedstock. Whether processing fresh grass, hay, or mixed feedstocks, our system consistently produces structurally dense, smooth-surfaced grass pellets.

Nettle

Corns

Hops

Wheat

Pasture Grass

Hay

Trefoil

straw

Raw Materials of Straw Pellets

The primary raw material for straw pellets is typically long-fiber crop stalks, sometimes blended with a certain proportion of grasses or grains. The lack of efficient straw pellet machine is a key factor hindering production. Our machinery is perfectly suited to this challenge and consistently produces high-quality pellets.

Corn Straw

Grain

Rice Straw

Corns

Wheat Straw

Cotton Stalks

Hay

Straw

Raw Materials of Husk Pellets

Agricultural husks are typically lightweight and prone to clogging equipment. Harder husks present challenges during pre-processing. RICHI biomass pellet machine is specifically designed to address these concerns. Regardless of your raw materials or formulation ratios, our husk pellet machine adapts seamlessly.

Rice Husks

Palm Shells

Peanuts Shells

Cotton Husks

Sunflower Seed Hulls

Grain

Coconut Shells

Walnut Shells

Design Highlights of biomass Pellet Machines

Our biomass pellet making machines across all models have undergone extensive R&D upgrades and market testing. They feature not only rational structures and powerful functionality but also energy efficiency, environmental friendliness, and strong adaptability. This helps you achieve ideal biomass pellet production.

Anti-Arching Feeder

This unit features a set of counter-rotating spiral paddles that effectively prevent material arching and accumulation.

Cutting Device

By adjusting this device, you can control the position of the internal blades to easily achieve different pellet lengths.

Forced Feeder

This device can be used to push accumulated material into the pelletizing chamber, thereby accelerating the process.

Exhaust vent

A fan and cyclone can be installed here. This enables high-temperature water vapour to be quickly removed from inside.

This advanced biomass pellet press machine delivers both high output and superior quality.

Beyond these, we’ve implemented numerous other innovative upgrades for pelletizer. For instance, the dual-roller design accommodates your specific pellet length requirements. The optimal ring die compression ratio helps you produce perfect pellets from various raw materials. If you’re seeking a highly efficient and energy-saving pelletizer, RICHI is your top choice. Contact us now to receive a special discount on biomass pellet machine prices!

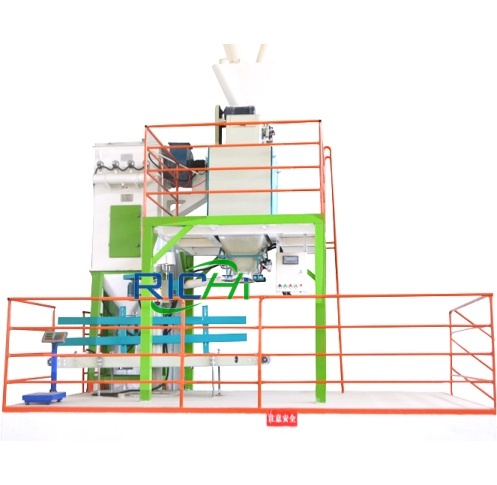

production line Solutions

Global Project

We have established partnerships with clients around the world through attentive service and superior biomass pellet machines. These cases have been implemented in multiple countries and regions including the United States, Russia, Australia, Mexico, and the Netherlands. Our outstanding biomass pellet solutions deliver significant economic benefits to customers, earning widespread praise.

United States

Mexico

1-2 T/H Flexible Husk Pellet Production Line

Iceland

3-4 T/H Straw Pellet Biomass Energy Plant

Indonesia

1-2 T/H Flexible Wood Pellet Production Line

Uzbekistan

1.5-2 T/H Refined Grass Pellet Production Project

Congo

1-1.2 T/H Flexible Wood Pellet Production Line

Germany

2-2.5 T/H Biomass Pellet Manufacturing Plant

Canada

2-3 T/H Wood Pellet Production Line

Thailand

3-5 T/H Automated Husk Pellet Production Line

Taiwan, China

1-1.2 T/H Flexible Wood Pellet Plant Project

Customer Reviews

Our innovations and advancements in biomass pellet mills are supported by customers. Many biomass pellet plants, large and small farms, heating providers, and other industries have shown their support and trust. We hope these experiences and insights will help you better understand our pellet machines.

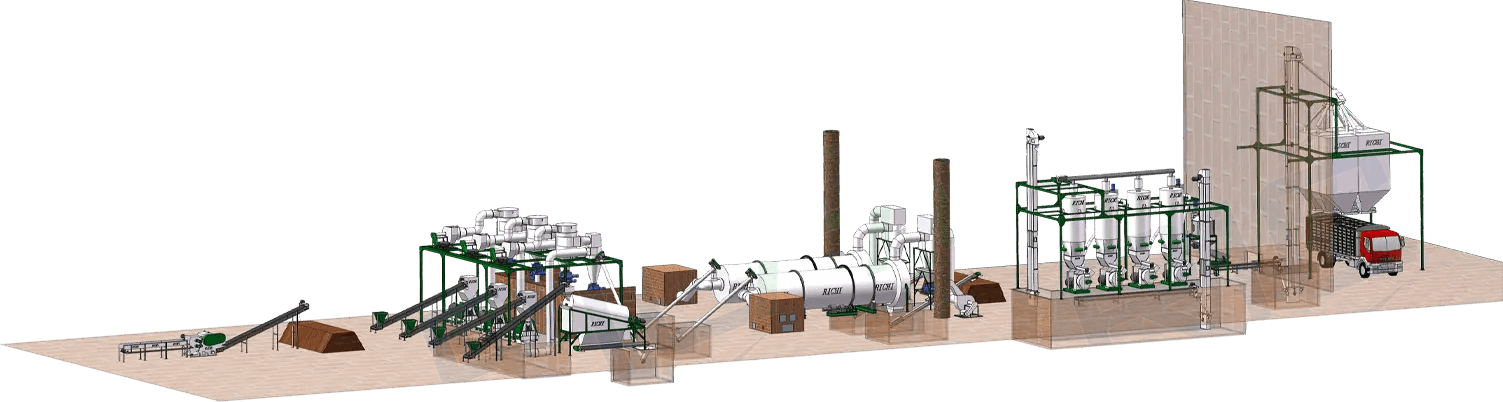

8-10T/H biomass Wood pellet production plant

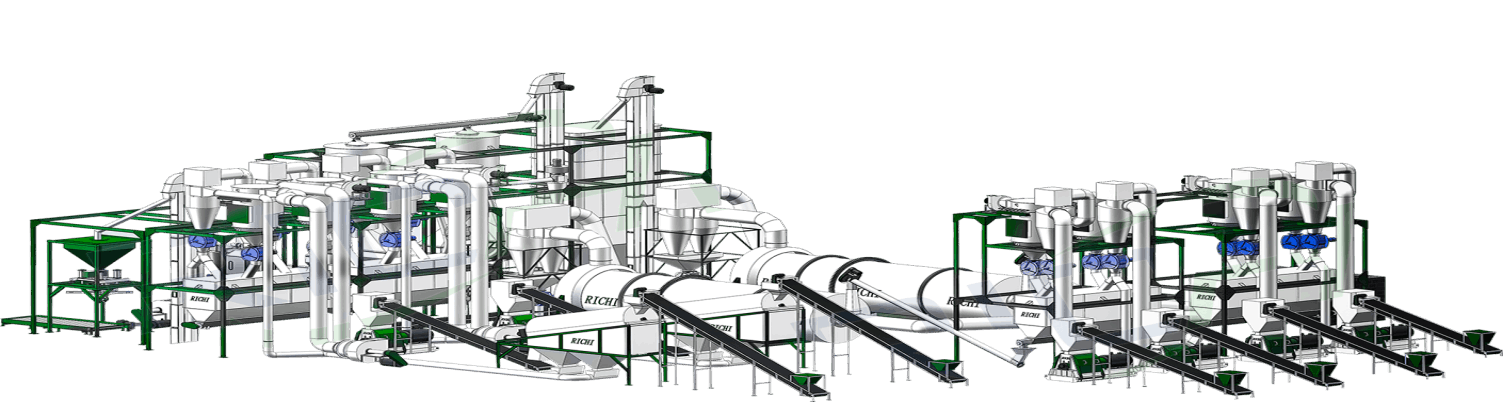

11-12T/H Grass pellet making plant

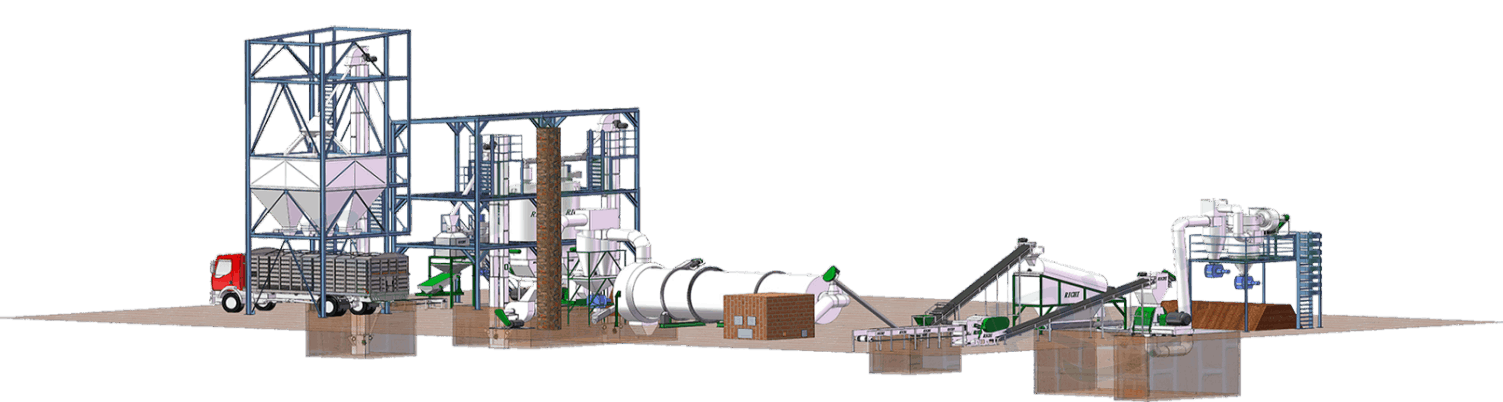

5-6T/H Wood pellet production line

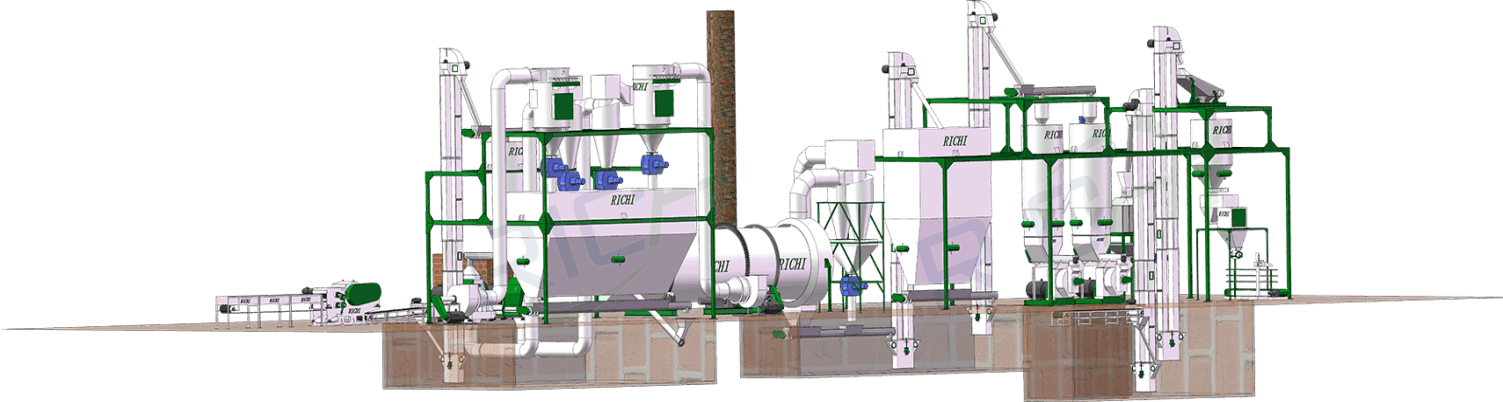

5-6T/H Husk pellet Manufacture Plant

20T/H Wood pellet Manufacturing Plant

Introduction to Biomass Pellet Production Line Sections

In order to achieve more precise and efficient production, we have divided the production line into multiple segments. Besides biomass pellet machines, these include raw material pretreatment, cooling, screening, and packaging equipment. Each segment works in coordination to provide you with a highly efficient and smooth production process.

Application of Biomass Pellet Production Line

We provide industrial biomass pellet machines and advanced production lines, which can manufacture conventional energy pellets and serve diverse applications. Examples include producing cat litter pellets, organic fertilizer, animal feed, fish feed, and more. They are adaptable to any field or industry utilizing biomass pellets. (View YouTube)

Cat Litter Manufacturing Plant

Organic Fertilizer Manufacturing Plant

Animal Feed Production

Fish Feed Production

News & Updates

Follow the global biomass energy market continues to expand, more customers are learning about our biomass pellet machine. Thanks to our customers’ trust and support, the collaborative projects are growing steadily. Here are some recent developments regarding biomass pellet projects.

Wood Pellet Project Client Visit …

After our online presentation and initial consultation, the client team visited our factory workshop on September 9, 2024. Our technical specialists accompanied them and provided a detailed introduction to the biomass pelletizer…

RICHI Machinery

25. Aug. 2025

Canadian Clay Pellet Machine Trial Run

The biomass pellet mill ordered by our Canadian client is designed for clay production. With our customized manufacturing process, it has now reached the trial run phase….

RICHI Machinery

25. Feb. 2025

Workers Performing Equipment Assembly

RICHI machinery manufacturing plant produces large volumes of equipment every day, and our workers assemble and inspect biomass pelletizers on a daily basis…

RICHI Machinery

30. Apr. 2024

On-site Installation of 5T Powder Production Line in Malaysia

The high-capacity 5 T powder production line, which customized for our Malaysian client has successfully arrived at the client’s facility. Our engineers have arrived on-site to provide equipment installation guidance and commissioning…